Method for preparing pyruvic acid by converting DL-lactic acid

A technology of pyruvic acid and lactic acid, applied in biochemical equipment and methods, microorganism-based methods, microorganisms and other directions, can solve problems such as difficulty in immobilization, limited application of lactate dehydrogenase, and difficulty in regeneration, so as to improve product conversion rate, The effect of maintaining product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

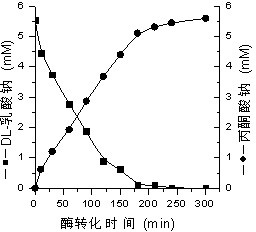

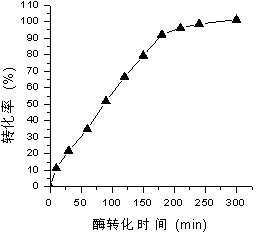

[0047] Example 1: Conversion of Pseudomonas fluorescens crude enzyme solution enzyme protein (70 mg / L) to DL-lactic acid with an initial concentration of 5.54 mM.

[0048] (1) Slant culture: inoculate the Pseudomonas fluorescens strain (ATCC948) on a solid slant minimal medium containing 2.0% agarose and 1.0% DL-sodium lactate, and cultivate at 30°C for 22 hours;

[0049] (2) Primary seed culture: The strains cultured in step (1) are connected to 1 to 2 loops with inoculation loops under aseptic conditions in 50-100 mL liquid minimal medium (LLM) containing 1.0% DL-sodium lactate, 30 Under the condition of ℃, shake culture on a shaker for 24 hours to prepare first-class seeds;

[0050] (3) Expanded culture: Inoculate 5% (volume ratio), then first-level seeds are placed in 500 mL LLM containing 1.0% DL-sodium lactate, and shake cultured on a shaker for 24 hours at 30°C to obtain second-level seed;

[0051] (4) Fermenter culture: 5% (volume ratio) inoculum, inoculated with secondary se...

Embodiment 2

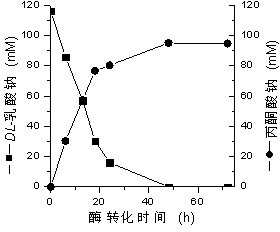

[0058] Example 2: Conversion of Pseudomonas fluorescens crude enzyme solution enzyme protein (300 mg / L) to DL-lactic acid with an initial concentration of 116 mM.

[0059] (1) Slant culture: Inoculate the Pseudomonas fluorescens strain on a solid slant minimal medium containing 1.5% agarose and 2.0% DL-sodium lactate, and cultivate at 30°C for 29 hours;

[0060] (2) Primary seed culture: Connect 1-2 loops of the strain cultured in step (1) with an inoculum loop under aseptic conditions in 50-100 mL liquid minimal medium (LLM) containing 2.0% DL-sodium lactate, 30 Under the condition of ℃, shake culture on a shaker for 24 hours to prepare first-class seeds;

[0061] (3) Expanded culture: Inoculate with 3% (volume ratio), the first-level seeds are added to 500 mL of LLM containing 2.0% DL-sodium lactate, and cultured on a shaker for 20 hours at 30°C to obtain the second-level seed;

[0062] (4) Fermenter culture: 5% (volume ratio) inoculum amount, inoculated with secondary seeds in 2L ...

Embodiment 3

[0068] Example 3: Conversion of Pseudomonas fluorescens crude enzyme solution enzyme protein (300 mg / L) to DL-lactic acid with an initial concentration of 1,080 mM.

[0069] (1) Slant culture: inoculate the Pseudomonas fluorescens strain on a solid slant minimal medium containing 2.0% agarose and 1.0% DL-sodium lactate, and cultivate at 30°C for 20 hours;

[0070] (2) Primary seed culture: The strains cultured in step (1) are connected to 1 to 2 loops with inoculation loops under aseptic conditions in 50-100 mL liquid minimal medium (LLM) containing 1.0% DL-sodium lactate, 30 Under the condition of ℃, shake culture on a shaker for 24 hours to prepare first-class seeds;

[0071] (3) Expanded culture: Inoculate 5% (volume ratio), then first-level seeds are placed in 500 mL LLM containing 1.0% DL-sodium lactate, and shake cultured on a shaker for 24 hours at 30°C to obtain second-level seed;

[0072] (4) Fermenter culture: 5% (volume ratio) inoculum, inoculated with secondary seeds in 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com