Method for increasing tin plated raw plate yield

A technology of yield and original plate, applied in heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve the problems of many cold-rolling processes of tin-plated original plates, affecting the surface quality of strip steel, scrapping the whole coil, and shortening the annealing cycle. Eliminate the quality defects of plate shape and the effect of good plate deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention discloses a method for improving the yield of tin-plated raw plates. Firstly, a set of inorganic salt coating device is added to the original degreasing unit for coating the inorganic salt solution. The production steps to improve the yield of tin-plated raw plates are as follows:

[0024] a. Carry out pickling, cold rolling and degreasing of strip steel;

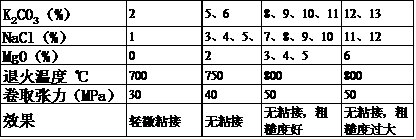

[0025] B, the steel strip after the degreasing is evenly coated with one deck inorganic salt solution, the weight percentage of this inorganic salt solution is coated according to a certain ratio; Specific instructions are shown in Table 1;

[0026] Table I:

[0027]

[0028] Wherein, the weight percent of inorganic salt solution is:

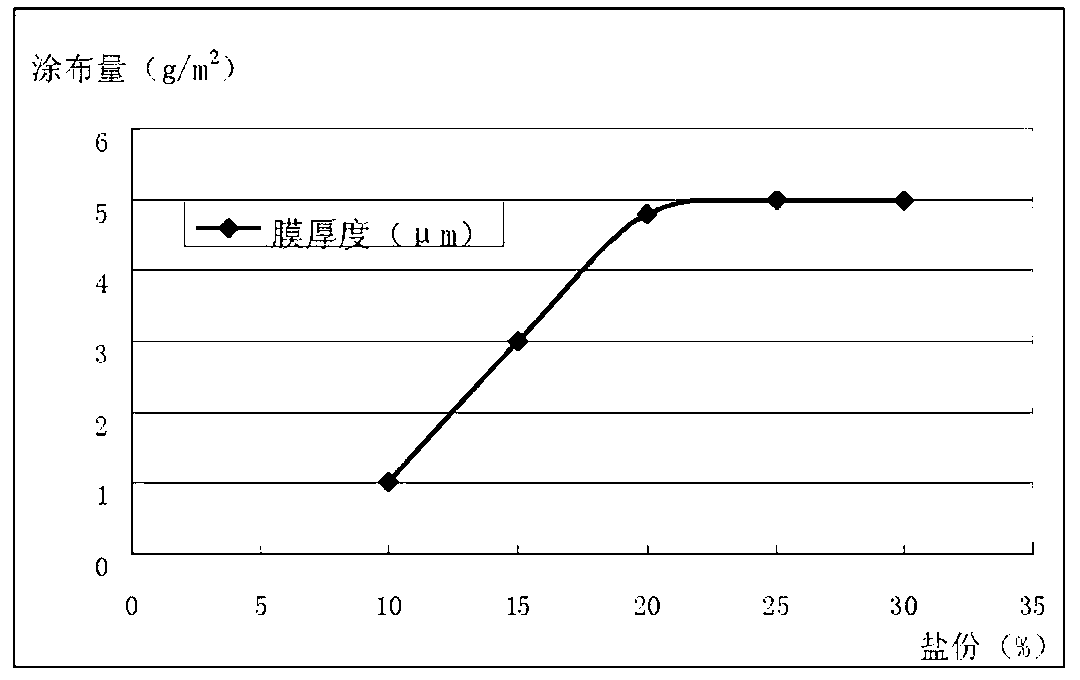

[0029] c, the coating amount of the inorganic salt is 1 ~ 50 g / m 3 , the passing speed of the board is 5~400m / min, among them, the amount of coating and the passing speed of the board can be selected according to the actual needs; in addition, please refer to figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com