Solution for surface metallization pretreatment of semiconductor P/N type refrigerating sheet and application method of same

A surface metal and semiconductor technology, applied in the manufacturing/processing of semiconductor devices, thermoelectric devices, metal material coating process, etc., can solve problems such as failure to obtain good results, and reduce sandblasting and nickel blasting steps and process consumption. The effect of reducing the energy and enhancing the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

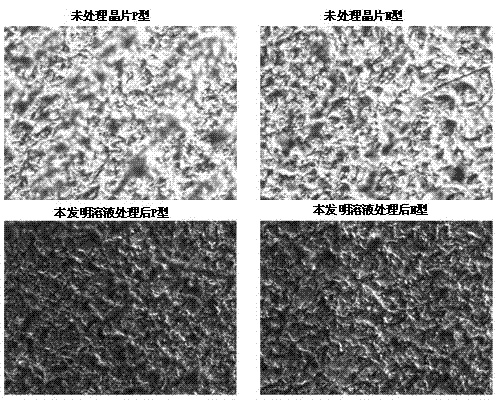

[0023] In a wafer (P-type or N-type) with a diameter of 2.7 cm and a thickness of 0.15 cm, after degreasing and washing with water, immerse in 8% (volume) hydrochloric acid, 5% (volume) nitric acid and 3g / L surfactant (especially Sodium dodecyl sulfonate or potassium dodecyl sulfonate), the rest is water, after 30 seconds to 100 minutes of treatment at a temperature of 12~36°C, take it out and wash it to get a smaller roughness, a more uniform surface, and a rougher surface. For after reducing 10~40% before using the technique of the present invention, can change over to metallization techniques such as electroplating nickel or sputtering ( figure 1 ).

Embodiment 2

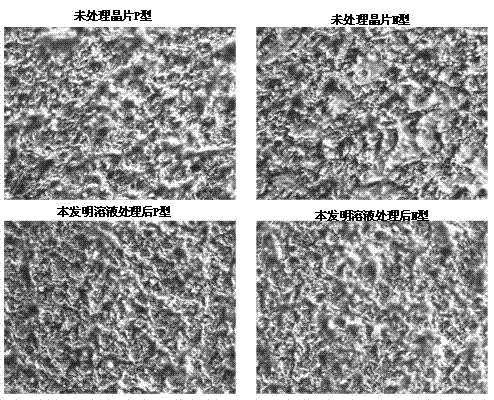

[0025] In a wafer (P-type or N-type) with a diameter of 2.7 cm and a thickness of 0.15 cm, after degreasing and washing with water, immerse in 28% (volume) hydrochloric acid, 30% (volume) nitric acid and 15g / L surfactant (especially sodium dodecylsulfonate or potassium dodecylsulfonate), and the rest is water, which is treated at a temperature of 12~36°C for 30 seconds to 100 minutes, then taken out and washed to obtain a smaller roughness, a more uniform surface, and a rougher surface. For after reducing 10~40% before using the technique of the present invention, can change over to metallization techniques such as electroplating nickel or sputtering ( figure 2 ).

Embodiment 3

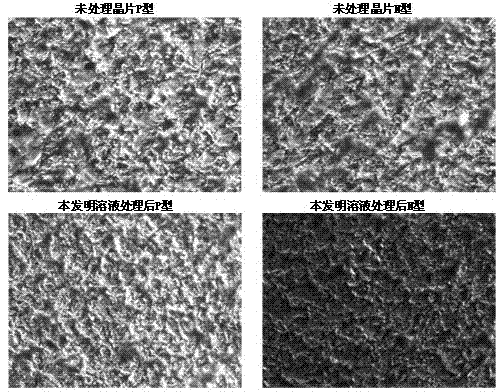

[0027] In a wafer (P-type or N-type) with a diameter of 2.54 cm and a thickness of 0.15 cm, after degreasing and washing with water, immerse in 10% (volume) hydrochloric acid, 18% (volume) nitric acid and 10g / L surfactant (especially Sodium dodecyl sulfonate or potassium dodecyl sulfonate), the rest is water, after 30 seconds to 100 minutes of treatment at a temperature of 12~36°C, take it out and wash it to get a smaller roughness, a more uniform surface, and a rougher surface. For after reducing 10~40% before using the technique of the present invention, can change over to metallization techniques such as electroplating nickel or sputtering ( image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com