A method for efficiently preparing laughing gas

A laughing gas, high-efficiency technology, applied in the field of environment and medical materials, energy, can solve the problem of catalytic activity to be improved, and achieve the effect of low equipment requirements and low process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

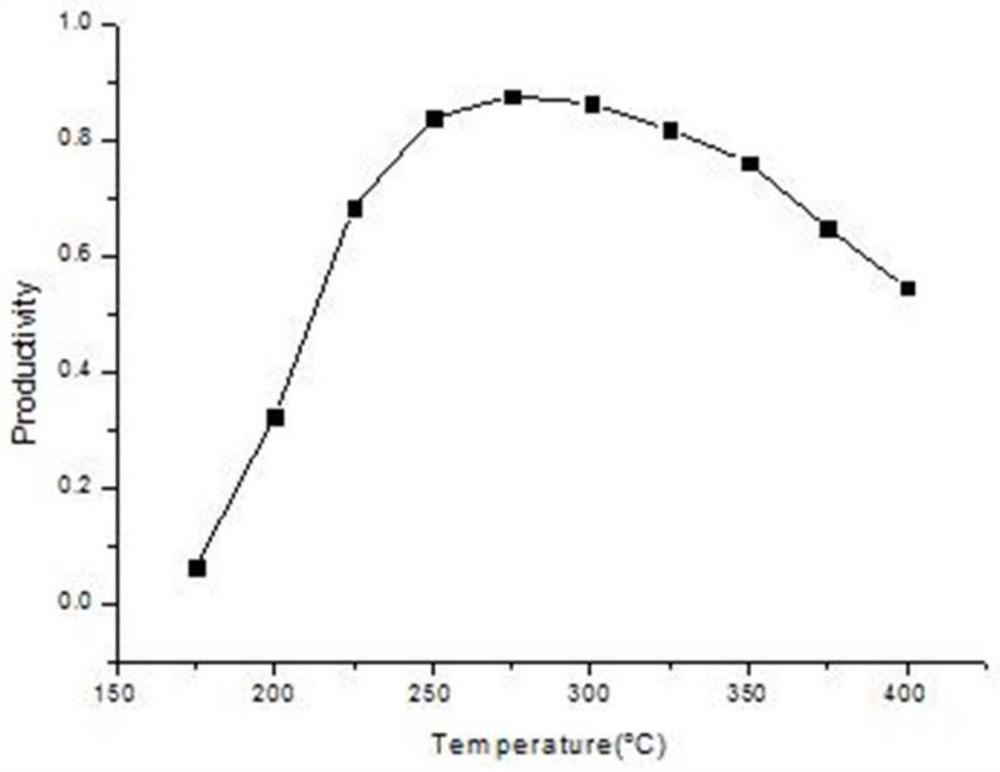

Image

Examples

Embodiment 1

[0026] Embodiment 1: adopt hydrothermal method and grinding sintering method to prepare the catalyst of producing laughing gas:

[0027] 1) Ce(NO with a concentration of 0.03mol / L 3 ) 3 20ml of solution, 140ml of NaOH solution with a concentration of 6mol / L, mixed and put into a hydrothermal kettle, heated and kept at 100°C for 24h; 2 Precipitated suspension;

[0028] 2) After centrifuging the solution with ultrapure water for 3 times, put it into a drying oven and dry it at 60°C for 12 hours;

[0029] 3) Grinding the taken sample into fine particles with an agate mortar, and then heat-treating at 450°C for 3 hours;

[0030] 4) Take the prepared rod-shaped CeO 2 990 mg of the carrier was ground for 10 minutes in an agate mortar to obtain CeO 2 fine powder of the carrier;

[0031] 5) Mix 20.2 mg of platinum acetylacetonate powder with ground CeO 2 Mix the powders and grind them in an agate mortar for 30 minutes to disperse them evenly to obtain mixed powders;

[0032] 6...

Embodiment 2

[0035] Embodiment 2: adopt hydrothermal method and grinding sintering method to prepare the catalyst of producing laughing gas:

[0036] 1) Ce(NO with a concentration of 0.03mol / L 3 ) 3 20ml of solution, 140ml of NaOH solution with a concentration of 6mol / L, mixed and put into a hydrothermal kettle, heated and kept at 100°C for 24h; 2 Precipitated suspension;

[0037] 2) After centrifuging the solution with ultrapure water for 3 times, put it into a drying oven and dry it at 60°C for 12 hours;

[0038] 3) Grinding the taken sample into fine particles with an agate mortar, and then heat-treating at 450°C for 3 hours;

[0039] 4) Take the prepared rod-shaped CeO 2 980 mg of the carrier was ground for 10 minutes in an agate mortar to obtain CeO 2 fine powder of the carrier;

[0040] 5) Mix 40.4 mg of platinum acetylacetonate powder with ground CeO 2 Mix the powders and grind them in an agate mortar for 30 minutes to disperse them evenly to obtain mixed powders;

[0041] 6) ...

Embodiment 3

[0044] Embodiment 3: adopt hydrothermal method and grinding sintering method to prepare the catalyst of producing laughing gas:

[0045] 1) Ce(NO with a concentration of 0.03mol / L 3 ) 3 20ml of solution, 140ml of NaOH solution with a concentration of 6mol / L, mixed and put into a hydrothermal kettle, heated and kept at 100°C for 24h; 2 Precipitated suspension;

[0046] 2) After centrifuging the solution with ultrapure water for 3 times, put it into a drying oven and dry it at 60°C for 12 hours;

[0047] 3) Grinding the taken sample into fine particles with an agate mortar, and then heat-treating at 450°C for 3 hours;

[0048] 4) Take the prepared rod-shaped CeO 2 980 mg of the carrier was ground for 10 minutes in an agate mortar to obtain CeO 2 fine powder of the carrier;

[0049] 5) Mix 57.4 mg of palladium acetylacetonate powder with ground CeO 2 Mix the powders and grind them in an agate mortar for 30 minutes to disperse them evenly to obtain mixed powders;

[0050] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com