Preparation method of epoxy resin composite material based on nano-silica particles

A technology of nano-silicon oxide and epoxy resin, which is applied in the field of preparation of epoxy resin composite materials, can solve the problems of easy explosion, large equipment investment, complicated process, etc., and achieve simple and easy operation, high mechanical properties, and low process consumption can low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

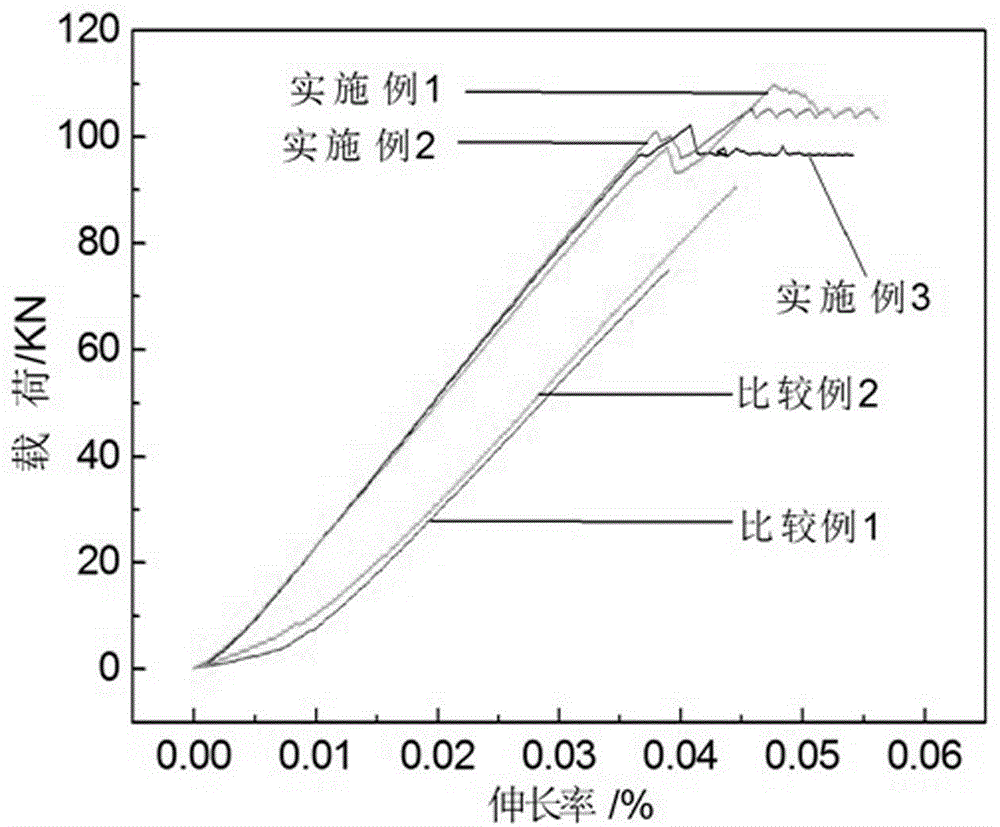

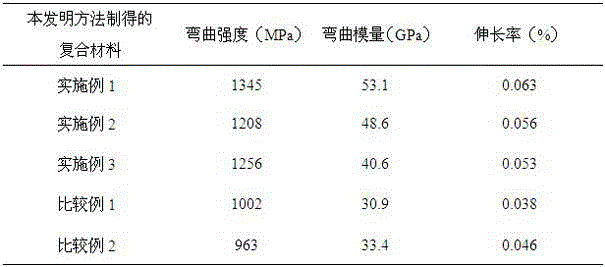

Embodiment 1

[0016] A kind of preparation method based on the epoxy resin composite material of nano silicon oxide particle, comprises the steps:

[0017] 1) Take ethanol and add coupling agent and nano-silica particles successively, mechanically stir for at least 60 minutes, and then ultrasonically disperse for at least 90 minutes, wherein the mass of coupling agent accounts for 3% of the mass of ethanol, and the coupling agent is KH- 550 silane coupling agents, the particle diameter of the nano silicon oxide particles is 45nm;

[0018] 2) heating and drying the ethanol solution in step 1) to obtain pretreated nano-silicon oxide particles, and grinding the pre-treated nano-silicon oxide particles for 40 minutes to obtain modified nano-silicon oxide particles;

[0019] 3) Take the epoxy resin and preheat it at 70°C for 23 minutes, add the modified nano-silica particles obtained in step 2) to the preheated epoxy resin, and then add Curing agent, mechanical stirring for at least 70 minutes,...

Embodiment 2

[0023] A kind of preparation method based on the epoxy resin composite material of nano silicon oxide particle, comprises the steps:

[0024] 1) Take ethanol and add coupling agent and nano-silicon oxide particles successively, mechanically stir for at least 80 minutes, and then ultrasonically disperse for at least 60 minutes, wherein the mass of coupling agent accounts for 2% of the mass of ethanol, and the coupling agent is titanic acid Ester coupling agent, the particle size of the nano silicon oxide particles is 30nm;

[0025] 2) heating and drying the ethanol solution in step 1) to obtain pretreated nano-silicon oxide particles, and grinding the pre-treated nano-silicon oxide particles for 35 minutes to obtain modified nano-silicon oxide particles;

[0026] 3) Take the epoxy resin and preheat it at 63°C for 27 minutes, add the modified nano-silica particles obtained in step 2) to the preheated epoxy resin, and then add Curing agent, mechanical stirring for at least 90 mi...

Embodiment 3

[0030] A kind of preparation method based on the epoxy resin composite material of nano silicon oxide particle, comprises the steps:

[0031] 1) Take ethanol and add coupling agent and nano-silica particles successively, mechanically stir for at least 70 minutes, and then ultrasonically disperse for at least 110 minutes, wherein the mass of coupling agent accounts for 1.5% of the mass of ethanol, and the coupling agent is alumina Ester coupling agent, the particle size of the nano silicon oxide particles is 150nm;

[0032] 2) heating and drying the ethanol solution in step 1) to obtain pretreated nano-silicon oxide particles, and grinding the pre-treated nano-silicon oxide particles for 50 minutes to obtain modified nano-silicon oxide particles;

[0033] 3) Take the epoxy resin and preheat it at 65°C for 25 minutes, add the modified nano-silica particles obtained in step 2) to the preheated epoxy resin, and then add Curing agent, mechanical stirring for at least 80 minutes, u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com