Agricultural residue wheat straw pencil and production method thereof

A technology of leftovers and wheat straw, applied in non-mechanical pencil, pen holder, printing and other directions, can solve the problems of waste of straw resources, traffic and ecological environment pollution, and achieve the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

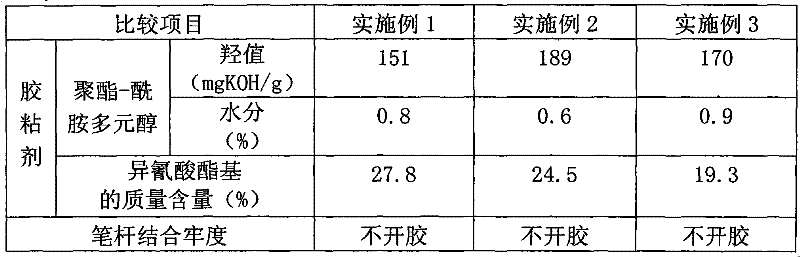

Embodiment 1

[0037] Add 100 parts by mass of recovered polyethylene terephthalate scraps and 30 parts by mass of ethanolamine to the reaction kettle, stir, heat to 190-220°C, and react for 2 hours to obtain polyester-amide polyol; cool down to 75 At ~80°C, add 150 parts by mass of toluene diisocyanate into the reaction kettle, stir and react for 3 hours, and obtain the isocyanate-terminated polyurethane adhesive;

[0038] The wheat straw is dried in the air, dried, and the water content is 14.9% by mass, crushed, sieved, and the whole powder of wheat straw with a particle size less than 20 meshes is collected, and sealed for later use;

[0039] Add the dry wheat straw powder into a high-speed mixer, spray the isocyanate-terminated polyurethane adhesive into it under high pressure, stir and blend at room temperature for 10 minutes, and obtain the glue-sprayed wheat straw powder, wherein the isocyanate-terminated polyurethane accounts for 1.5% of the absolute dry mass of the wheat straw powde...

Embodiment 2

[0042] Add 100 parts by mass of recovered polyethylene terephthalate scraps and 50 parts by mass of ethanolamine to the reaction kettle, stir, heat to 190-220°C, and react for 2 hours to obtain polyester-amide polyol; cool down to 75 At ~80°C, add 180 parts by mass of toluene diisocyanate into the reaction kettle, stir and react for 3 hours, and obtain the isocyanate-terminated polyurethane adhesive;

[0043] Drying the wheat straw, drying, the water content of the wheat straw is 3%, crushing, sieving, collecting the whole powder of the wheat straw with a particle size less than 20 meshes, and sealing it for later use;

[0044] Add the dry wheat straw powder into a high-speed mixer, spray the isocyanate-terminated polyurethane adhesive into it under high pressure, stir and blend at room temperature for 10 minutes, and obtain the glue-sprayed wheat straw powder, wherein the isocyanate-terminated polyurethane accounts for 4% of the absolute dry mass of the wheat straw powder;

[0...

Embodiment 3

[0047] Add 100 parts by mass of recycled polyethylene terephthalate scraps and 40 parts by mass of ethanolamine to the reaction kettle, stir, heat to 190-220°C, and react for 2 hours to obtain polyester-amide polyol; cool down to 75 At ~80°C, add 165 parts by mass of toluene diisocyanate into the reaction kettle, stir and react for 3 hours, and obtain the isocyanate-terminated polyurethane adhesive;

[0048] Drying the wheat straw, drying, the water content of the wheat straw is 9%, crushing, sieving, collecting the whole wheat straw powder with a particle size less than 20 meshes, and sealing it for later use;

[0049] Add the dry wheat straw powder into a high-speed mixer, spray the isocyanate-terminated polyurethane adhesive into it at high pressure, stir and blend at room temperature for 10 minutes, and obtain the glue-sprayed wheat straw powder, wherein the isocyanate-terminated polyurethane accounts for 2.5% of the dry mass of the wheat straw powder;

[0050] Filling the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com