Sensitive material for flexible temperature sensor

A technology of temperature sensor and sensitive material, applied in the direction of thermometers, thermometers, instruments, etc. which use electrical/magnetic components directly sensitive to heat, it can solve the problem that the temperature sensing function and flexibility cannot be combined, and the tactile sensor array cannot be applied. Array structure requirements are high, to achieve good temperature-sensitive characteristics, improve flexibility, and ensure the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

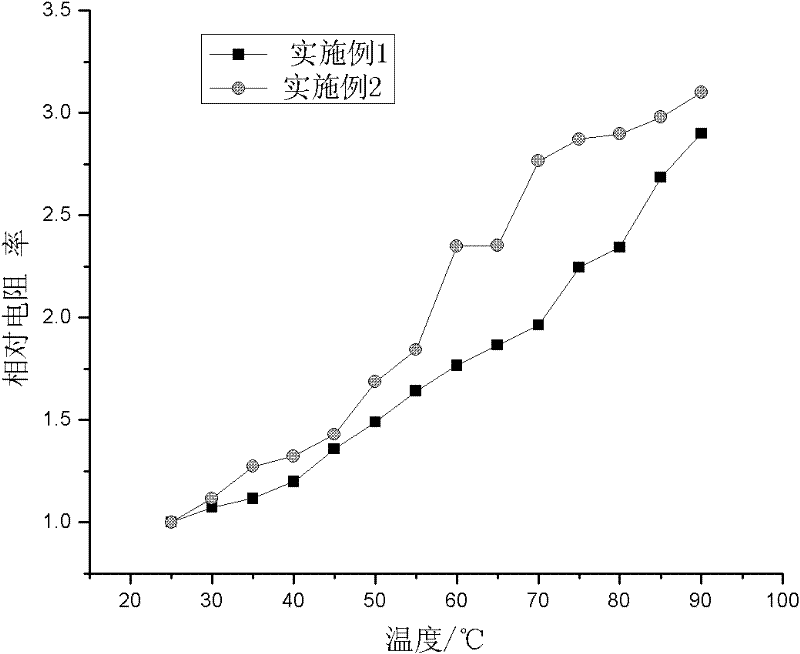

Embodiment 1

[0032] The composite system of conductive carbon fiber, nano-carbon fiber and liquid silicone is formulated according to the following weight ratio:

[0033] One-component liquid silicone rubber RTV GD401: 100 parts;

[0034] Conductive carbon fiber: 8 parts;

[0035] Carbon nanofiber: 2 parts;

[0036] Dispersant: 10 parts.

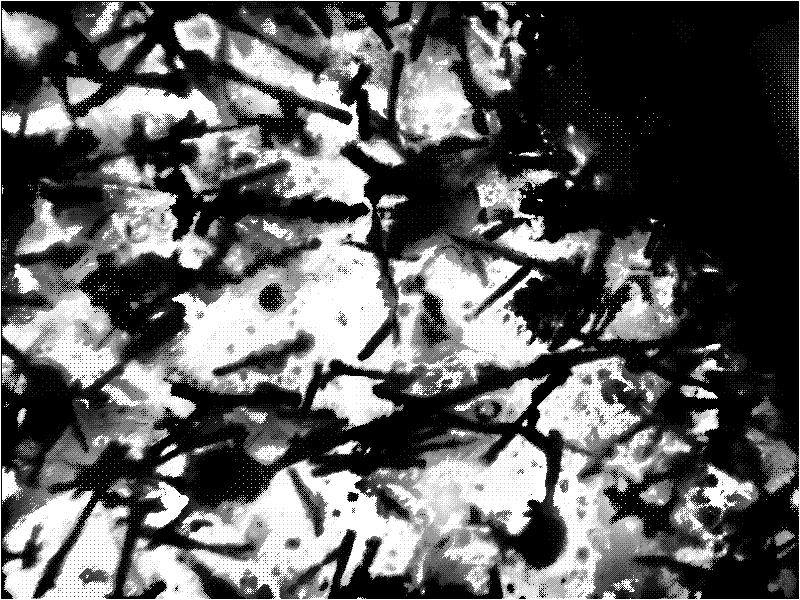

[0037] The conductive carbon fiber is ECP-CF with an average length of 0.2mm, an average diameter of 11-15μm, and a resistivity of 4-7×10 -3 Ω·cm.

[0038] The carbon nanofiber is TNCF with an average length of 5-50 μm, an average diameter of 200-400 nm, and a resistivity of 0.1×10 -3 Ω·cm.

[0039] The dispersant is distilled naphtha, density 650-750kg / m 3 .

[0040] making process:

[0041] Under normal temperature and normal pressure, 8 parts of conductive carbon fiber ECP-CF, 2 parts of nano-carbon fiber TNCF and 10 parts of dispersant were dispersed by FS-150 ultrasonic processor for 30-40 minutes to obtain suspension A; Add to 100 parts of...

Embodiment 2

[0044] The composite system of conductive carbon fiber, nano-carbon fiber and liquid silicone is formulated according to the following weight ratio:

[0045] Two-component polydimethylsiloxane PDMS DC-184: 100 parts, including 90 parts of agent A and 10 parts of agent B;

[0046] Conductive carbon fiber: 10 parts;

[0047] Carbon nanofiber: 4 parts;

[0048] Dispersant: 10 parts.

[0049] The conductive carbon fiber is ECP-CF with an average length of 0.2mm, an average diameter of 11-15μm, and a resistivity of 4-7×10 -3 Ω·cm.

[0050] The carbon nanofiber is TNCF with an average length of 5-50 μm, an average diameter of 200-400 nm, and a resistivity of 0.1×10 -3 Ω·cm.

[0051] The dispersant is distilled naphtha, density 650-750kg / m 3 .

[0052] making process:

[0053]At normal temperature and pressure, 10 parts of conductive carbon fiber ECP-CF, 4 parts of nano-carbon fiber TNCF and 10 parts of dispersant were dispersed by FS-150 ultrasonic processor for 30-40 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com