Sputtering target and preparation method thereof

A sputtering target and oxide technology, applied in the field of sputtering targets, can solve the problems of flat target cracks, backplane warpage, and high coating stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

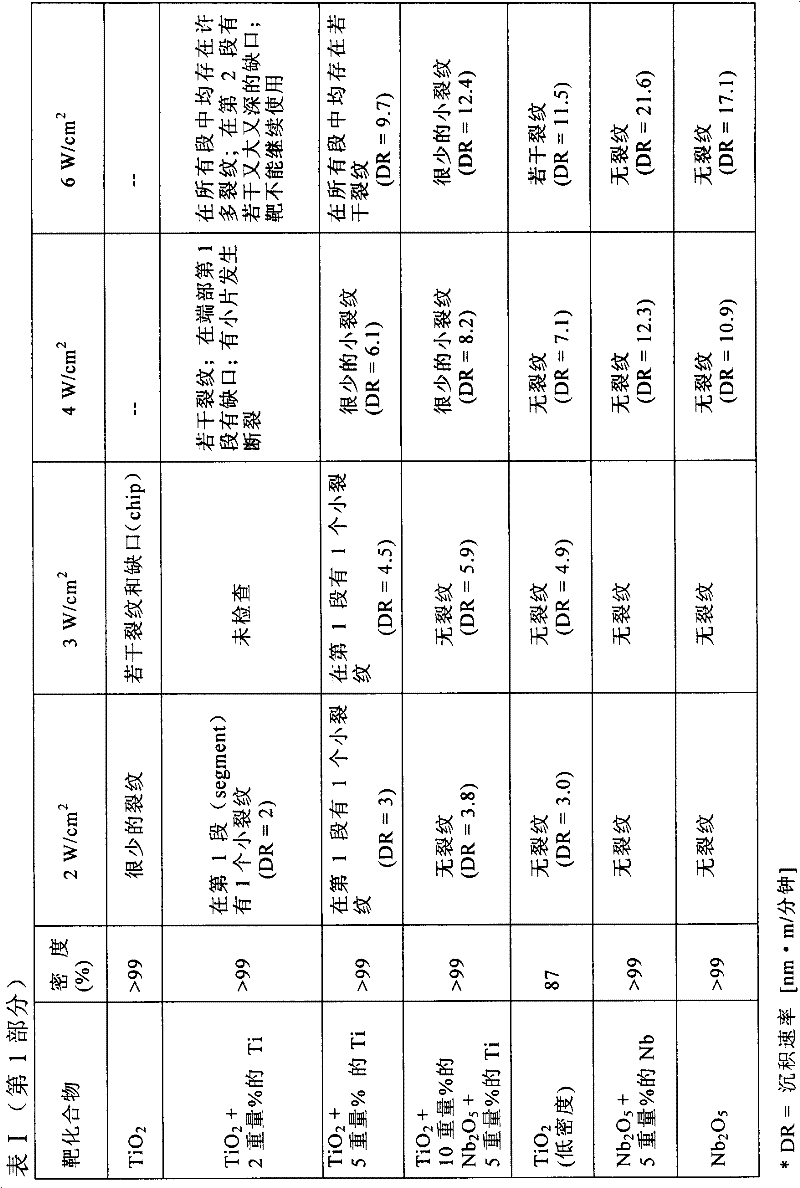

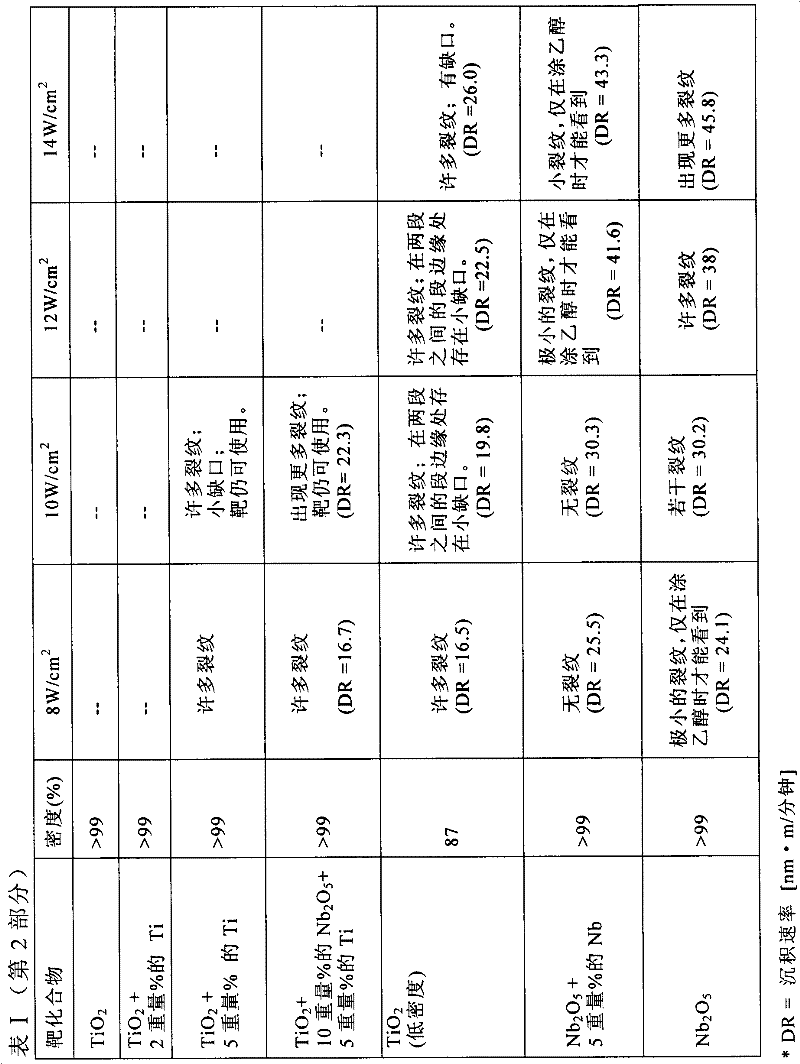

Examples

Embodiment 1

[0059] A sputtering target preparation method according to an exemplary embodiment of the present invention may include the following steps:

[0060] Dry mixing of metal oxide powders with metal powders, and

[0061] • Shaping the mixture by hot pressing or hot isostatic pressing.

[0062] In these exemplary embodiments, the metal powder may preferably be 10% by mass to 20% by mass. This is for pervasive distribution. The particle size of the metal oxide powder and the metal powder is preferably 1 μm to 150 μm. Segregation after mixing must be avoided by careful optimization between metal and oxide particle size, shape and density. Depending on the oxide used, it may be preferable to shape the mixture at temperatures between 600°C and 1400°C.

Embodiment 2

[0064] A sputtering target preparation method according to yet another exemplary embodiment of the present invention may include the following steps:

[0065] mixing metal oxide powders with metal powders into a slurry, and

[0066] Carry out spray drying;

[0067] shaping the mixture by pressing; and

[0068] • Carry out sintering in an inert atmosphere or in vacuum.

[0069] In these exemplary embodiments, the slurry may include a solvent, where the solvent may be water or any alcohol. During the implementation of the sputtering target preparation method, sputtering targets with different densities can be obtained by changing sintering parameters (eg, temperature and time). In this way, low-density sputtering targets with a density of 70% to 95%, preferably 80% to 95%, can be produced.

Embodiment 3

[0071] A sputtering target preparation method according to yet another exemplary embodiment of the present invention may include the following steps:

[0072] Mix metal oxide powder or a mixture of several metal oxide powders into a slurry,

[0073] Carry out spray drying;

[0074] shaping the mixture by pressing; and

[0075] • Carry out sintering in an inert atmosphere or in vacuum.

[0076] In these exemplary embodiments, the slurry may include a solvent, where the solvent may be water or any alcohol. During the implementation of the sputtering target preparation method, sputtering targets with different densities can be obtained by changing sintering parameters (eg, temperature and time). In this way, low-density sputtering targets with a density of 70% to 95%, preferably 80% to 95%, can be produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com