Method for degrading polychlorinated biphenyl in soil by utilizing mixed powder of zero-valence iron and magnesium metals

A zero-valent metal and mixed powder technology is applied in the field of remediation and environmental treatment of polychlorinated biphenyl-contaminated soil, which can solve the problems of complex operating conditions and high costs, and achieve the effects of simplifying reaction conditions, easy operation and saving soil remediation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 5.6g of iron powder and 3.6g of magnesium powder respectively, fully mix the weighed iron powder and magnesium powder, grind them in a mortar, and pass through a 100-mesh sieve to obtain the desired metal-iron-magnesium mixed powder.

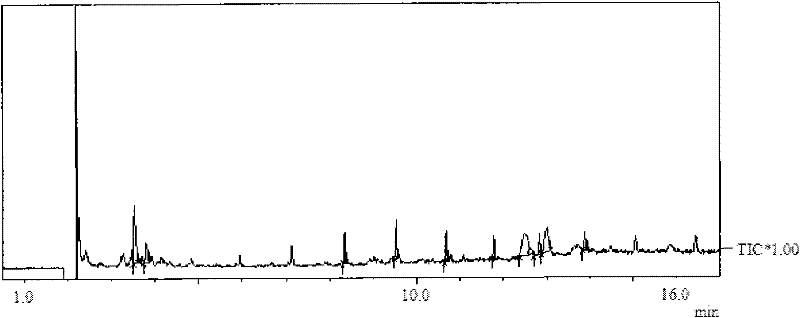

[0031] Weigh 10 g of PCBs-contaminated soil (PCBs concentration: 2258.85 μg / kg), add 0.01 g of the zero-valent metal iron-magnesium mixed powder prepared above, mix well, add 1 mL of deionized water to adjust the soil humidity, under indoor conditions Stand still and react for 9 hours. The reacted soil samples were dried and extracted for pretreatment, and detected by gas chromatography, the concentration of PCBs in the soil was 358.38 μg / kg, and the degradation efficiency was 84.13%.

Embodiment 2

[0033] Weigh 10g of polychlorinated biphenyl contaminated soil (PCBs concentration: 2258.85 μg / kg), add 0.02g of the zero-valent metal iron-magnesium mixed powder prepared in Example 1, mix well, add 1mL of deionized water to adjust the soil humidity, in The reaction was left to stand for 9 hours under room conditions. After the reaction, the soil sample was dried and extracted for pretreatment, and detected by gas chromatography, the concentration of PCBs in the soil was 246.2 μg / kg, and the degradation efficiency reached 89.10%.

Embodiment 3

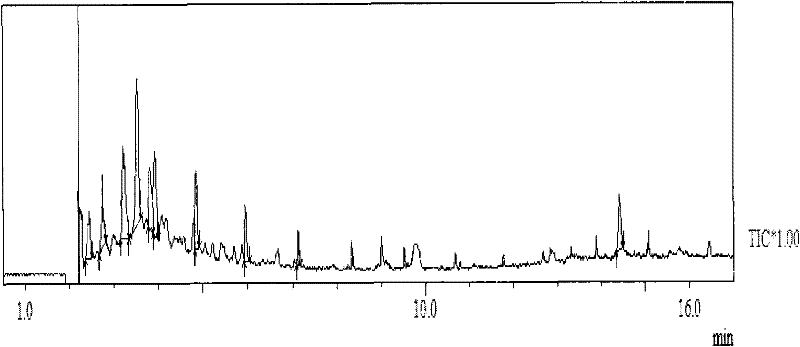

[0035] Weigh 10 g of polychlorinated biphenyl contaminated soil (PCBs concentration: 2258.85 μg / kg), add 0.02 g of the mixed powder of zero-valent metal iron and magnesium prepared in Example 1, mix well, and add 1 mL of NH with a mass fraction of 2%. 4 Cl solution was used to adjust the soil humidity, and the reaction was allowed to stand for 9 hours under indoor conditions. The reacted soil samples were dried and extracted for pretreatment, and detected by gas chromatography, the concentration of PCBs in the soil was 107.91 μg / kg, and the degradation efficiency was 95.22%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com