Thioctic acid-modified hydrophilic polymer for side chain

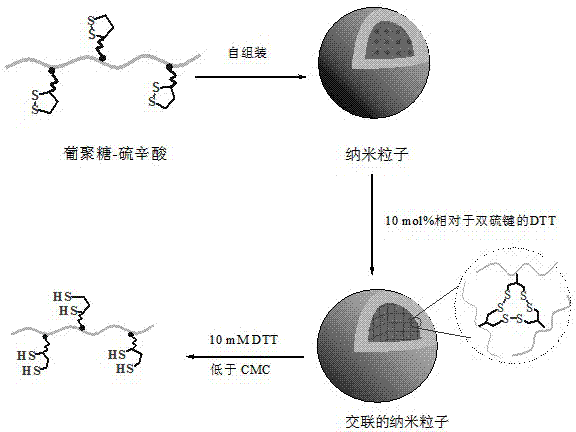

A hydrophilic polymer and amphiphilic polymer technology, applied in the field of modified hydrophilic polymers, can solve problems such as environmentally sensitive nano-drug carriers, and achieve the improvement of encapsulation efficiency, efficiency and bioavailability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

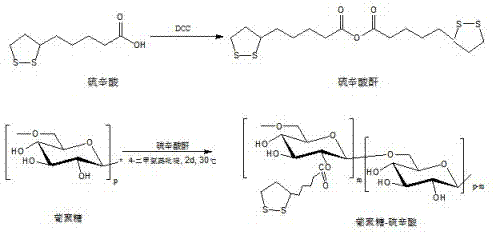

[0039] Embodiment one, synthetic polymer Dex-LA ( M ndextran =20 kDa, DS = 80%)

[0040] Under the protection of argon, dissolve lipoic acid (0.639 g, 3.10 mmol) in 10 mL of dichloromethane, add it into a 50 mL Schlenk vacuum-sealed bottle, and dissolve DCC in 5.0 mL of dichloromethane under argon (0.384g, 1.86 mmol) into a sealed bottle, put the bottle in an oil bath at 30°C, stir and react for 22 hours, cool, filter to remove the urea generated in the reaction, spin the filtrate to obtain lipoic anhydride after removing the solvent .

[0041] The lipoic anhydride obtained above was added to 3 mL of anhydrous-treated dimethyl sulfoxide. Add dextran (0.25 g, 1.55 mmol AHG) dissolved in 19 mL of dimethyl sulfoxide to a 50 mL three-neck flask. Under argon protection, add lipoic anhydride and 2 mL of dimethyl sulfoxide 4-Dimethylaminopyridine (0.189g, 1.55 mmol), the reactor was placed in an oil bath at 30°C, and after stirring for 48 hours, it was precipitated into cold eth...

Embodiment 2

[0042] Embodiment two, synthetic polymer Dex-LA ( M ndextran =20 kDa, DS = 20%)

[0043] Under the protection of argon, dissolve lipoic acid (0.255 g, 1.24 mmol) in 10 mL of dichloromethane, add it to a 50 mL Schlenk vacuum-sealed bottle, and dissolve DCC in 5.0 mL of dichloromethane under argon Add (0.154g, 0.74 mmol) into a sealed bottle, put the bottle in an oil bath at 30°C, stir and react for 22 hours, cool, filter to remove the urea generated in the reaction, and spin the filtrate to obtain lipoic anhydride after removing the solvent .

[0044] The lipoic anhydride obtained above was added to 3 mL of anhydrous-treated dimethyl sulfoxide. Add Dextran (0.25 g, 1.55 mmol AHG) dissolved in 19 mL of dimethyl sulfoxide to a 50 mL three-necked flask, and then add lipoic anhydride and 4-dimethylamino dissolved in 2 mL of dimethyl sulfoxide in sequence under argon protection Pyridine (0.076g, 0.62 mmol), the reactor was placed in an oil bath at 30°C, and after stirring for 4...

Embodiment 3

[0045] Embodiment three, synthetic polymer Dex-LA ( M ndextran =70 kDa, DS = 40%)

[0046] Under the protection of argon, dissolve lipoic acid (0.352 g, 1.71 mmol) in 10 mL of dichloromethane, add it into a 50 mL Schlenk vacuum-sealed bottle, and dissolve DCC in 5.0 mL of dichloromethane under argon Add (0.212g, 1.03 mmol) into a sealed bottle, put the bottle in an oil bath at 30°C, stir and react for 22 hours, cool, filter to remove the urea generated in the reaction, spin the filtrate to obtain lipoic anhydride after removing the solvent .

[0047] The lipoic anhydride obtained above was added to 3 mL of anhydrous-treated dimethyl sulfoxide. Add Dextran (0.25 g, 1.55 mmol AHG) dissolved in 19 mL of dimethyl sulfoxide to a 50 mL three-necked flask, and then add lipoic anhydride and 4-dimethylamino dissolved in 2 mL of dimethyl sulfoxide in sequence under argon protection Pyridine (0.104g, 0.86mmol), the reactor was placed in an oil bath at 30°C, stirred and reacted for 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com