Application of gene for coding 4-hydroxyphenylphruvic acid dioxygenase

A technology of pyruvate dioxygenase and hydroxybenzene, applied in the field of microbial genetic engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Construction of XC_0450 Gene Mutant in Xcc

[0054] The suicide plasmid pK18mob was used to mutate the XC_0450 gene, and the specific method was described by Windgassen et al. (FEMS Microbiol. Lett. 2003, 193: 201-205).

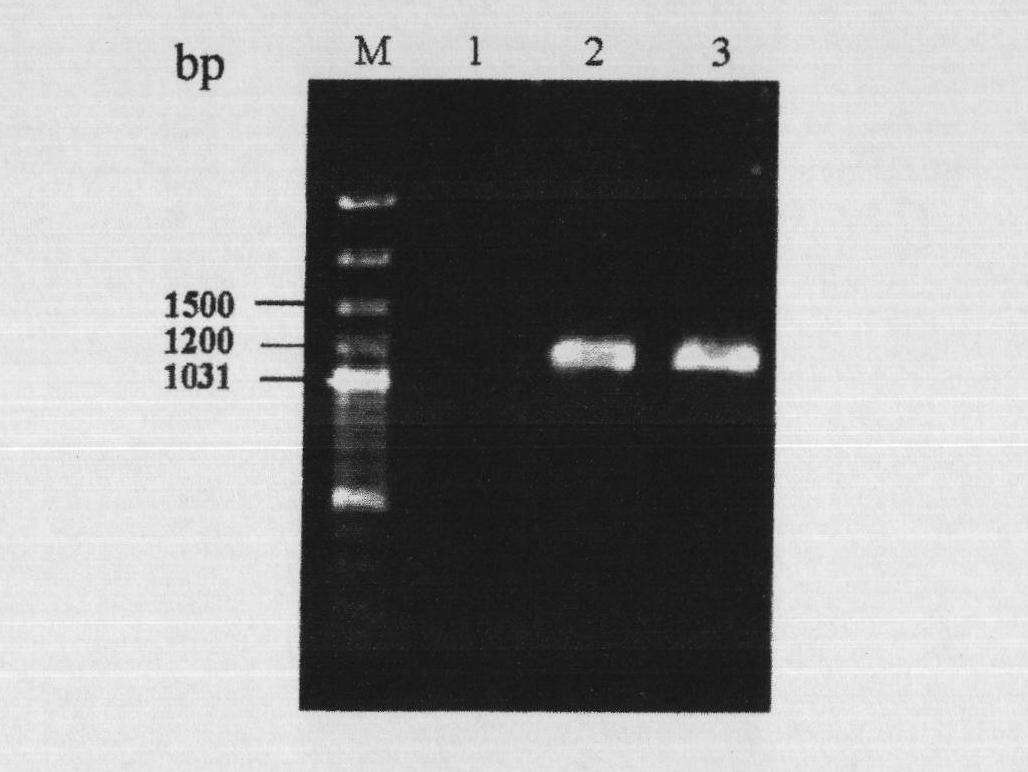

[0055] According to the DNA sequence of the XC_0450 gene in the 8004 strain of Xcc (genome sequence number NC_007086, Qian et al., 2005), design primer 0450F / R (0450F: CCC GGATCC AGGTCACCCACCTTCGAAAATC;0450R:CCC GGATCC CATGTTGCCGAAGTACAGGT), using the total DNA of Xcc 8004 strain as template, amplify XC_0450 by PCR method (pre-denaturation at 95°C for 4 min; denaturation at 95°C for 1 min, refolding at 55°C for 30 s, extension at 74°C for 30 s, 30 cycles; extension at 74°C for 5 min) to amplify XC_0450 The homologous fragment of the 523bp region between 5 and 528bp within the ORF of the gene. For the convenience of cloning, corresponding restriction site sequences (that is, the underlined part in the above DNA primer sequences) were added to the 5'...

Embodiment 2

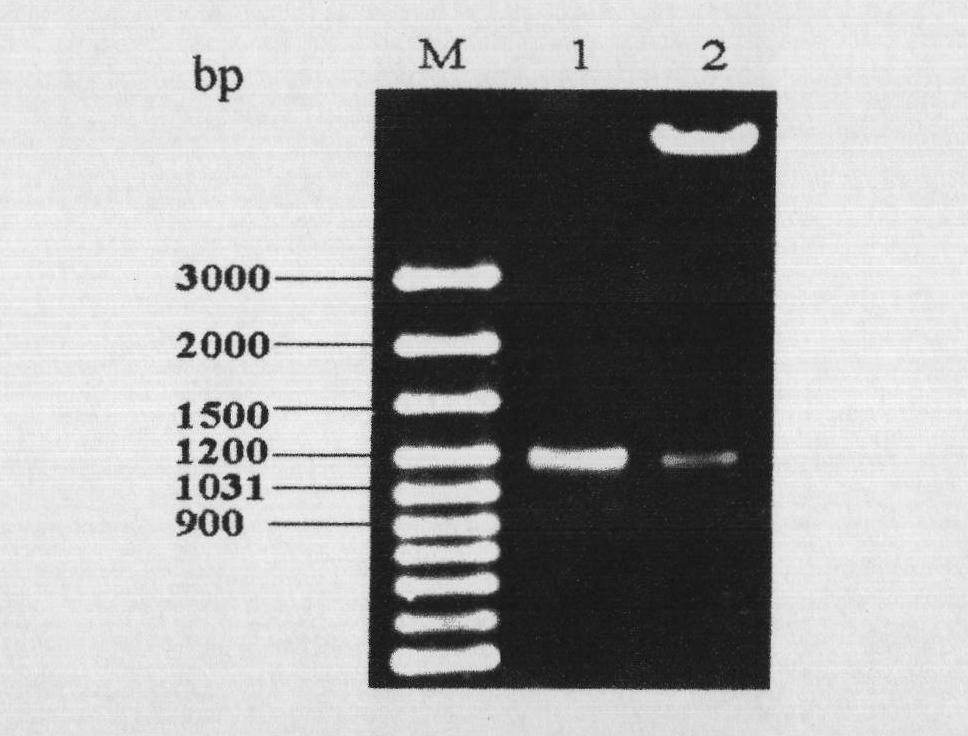

[0058] Cloning and sequence determination of XC_0450 gene and construction of genetically engineered bacteria carrying multiple copies of XC_0450 gene

[0059] According to the DNA sequence of XC_0450 gene (NC_007086, Qian et al., 2005), design primer C0450F / R (C0450F: CCC GGATCC TAGCGTGGAGAAACGACGAT; C0450R: CCC AAGCTT ATCCCGAGTAGCGAATCACC), using the total DNA of the Xcc 8004 strain as a template, the PCR method (pre-denaturation at 95°C for 4 min; denaturation at 95°C for 1 min, refolding at 55°C for 30 s, extension at 74°C for 2 min, 30 cycles; extension at 74°C for 5 min) was used to amplify the The full-length sequence of the gene (1165 bp DNA fragment including 63 bp upstream and 31 bp downstream of the XC_0450 gene coding region). For the convenience of cloning, the restriction site sequences of BamHI and HindIII (underlined part in the DNA primer sequence above) were respectively added to the 5' ends of the primers. The obtained DNA fragment was cloned into the ve...

Embodiment 3

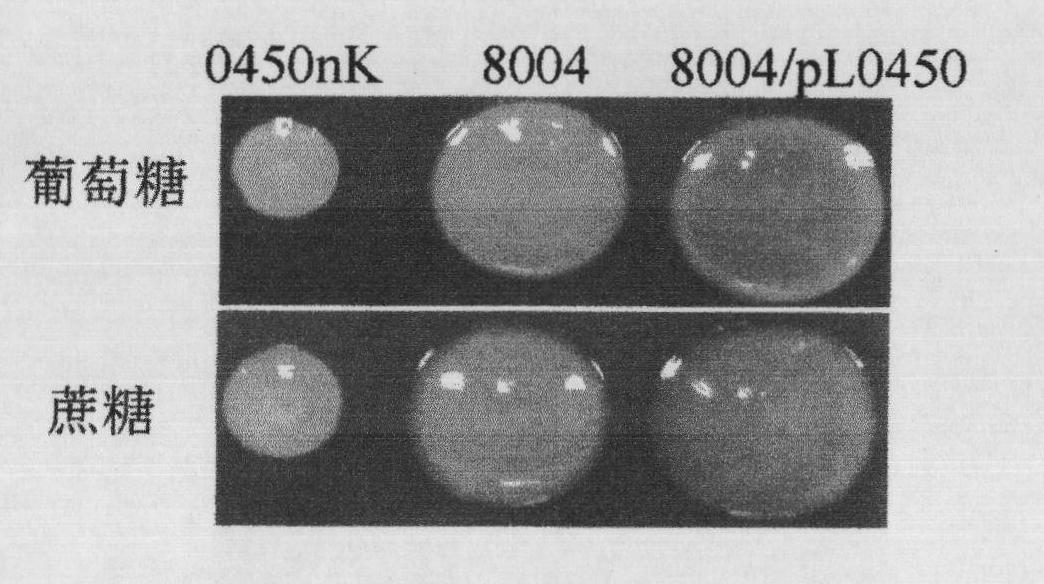

[0062] XC_0450 Gene Mutant and Engineering Bacteria 8004 / pL0450 Correlation Detection with Xanthan Gum Production

[0063] The qualitative and quantitative detection of Xcc xanthan gum production was carried out with reference to the method described by Tang et al. (Mol. Gen. Genet. 1991, 226: 409-417).

[0064] (1) Qualitative detection

[0065] Mutant 0450nK of the XC_0450 gene, genetically engineered bacteria 8004 / pL0450 carrying multiple copies of XC_0450 were inoculated into 10 mL of NYG (per liter of solution contained 5 g of peptone, 3 g of yeastextract and 20 g of glycerol, pH 7.0; Daniels et al., 1984 ) culture medium, after cultivating on a shaker at 28°C overnight, accurately take 1 μL of the culture with a pipette, and inoculate them on NYG medium plates containing 2% glucose or sucrose, respectively. The wild-type strain 8004 was used as a control, and cultivated for 5 days.

[0066] The results showed that the bacterium colony formed by the mutant 0450nK was sma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com