Preparation method of microbial flocculant for purifying aquaculture seawater

A microbial flocculant and seawater purification technology, applied in the field of biotechnology and bioengineering, can solve the problem that the removal effect of soluble organic matter, inorganic matter and total N and P is not good, bacteria and pollutants cannot be effectively aggregated, and they cannot play a role. Reaction effect and other problems, to achieve the effect of good application value, low production cost, and accelerated flocculation and sedimentation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Microbial flocculant preparation and expanded cultivation of production strains

[0031] (1) Expanded cultivation of production strains

[0032] ① Medium

[0033] Klebsiella (Klebsilla sp.) LDX1-1 slant medium: sucrose 12g / L, NH 4 NO 3 1.5g / L, K 2 HPO 4 1.0g / L, MgSO 4 0.4g / L, NaCl 0.3g / L, FeSO 4 0.01g / L, agar powder 1.5%.

[0034] Xanthomonas campestris CICC10258 slant medium: peptone 5g / L, beef extract 3g / L, sodium chloride 5g / L, agar powder 1.5%.

[0035] Shake flask culture medium: (sucrose 60%+glucose 40%) 15g / L, mixed nitrogen source (NH 4 NO 3 55%+((NH 4 ) 2 SO 4 45%) 3g / L, K 2 HPO 4 1.2g / L, MgSO 4 0.6g / L, NaCl 0.3g / L, FeSO 4 0.01g / L.

[0036] ②Inoculation and culture

[0037] Slant strain culture: inoculate Klebsiella LDX1-1 (CGMCC No.11330) and Xanthomonas campestris CICC10258 into the slant medium respectively, and culture at 24-32°C for 24-48h until the slant strains grow vigorously ;

[0038] Expanded cultivation of shak...

Embodiment 2

[0039] Example 2 Microbial flocculant fermentation

[0040] (1) Fermentation culture (high concentration magnesium salt fermentation)

[0041] Fermenter medium: sucrose 26g / L, cornstarch 15g / L, mixed nitrogen source (NH 4 NO 3 55%+((NH 4 ) 2 SO 4 45%) 2.7g / L, K 2 HPO 4 1.1g / L, MgSO 4 10g / L, NaCl 0.3, FeSO 4 0.015g / L, MnSO 4 0.03g / L.

[0042] Fermentation medium is inoculated with Klebsiella LDX1-1, Xanthomonas campestris CICC10258 mixed shake flask expansion culture liquid bacterial classification by volume ratio 2.2% inoculum (Klebsiella in the mixed shake flask expansion culture liquid bacterial classification Bacillus LDX1-1, Xanthomonas campestris CICC10258 expansion culture liquid strain volume ratio is 6:4). Fermentation adopts high-concentration magnesium salt fermentation, and the amount of magnesium sulfate required for fermentation is added to the cultured fermentation medium in the proportion of 20%, 35%, and 45% of the total amount when preparing t...

Embodiment 3

[0045] Embodiment 3: produce solid microbial flocculant

[0046] The liquid microbial flocculant of Example 1 was added 2.0 times the volume of 95% (V / V) ethanol under 70r / min full stirring to obtain a precipitate, which was centrifuged with a centrifuge for 8min, and the resulting solid was washed with 90% (V / V) V) Fully wash with ethanol, dry the alcohol-containing solids with a vacuum desiccator at a vacuum degree of -0.07Mpa and 42°C until the moisture is less than 5%, and pulverize them into 80 mesh powders with a pulverizer. The yield is 2.6%, and the flocculation rate is ≥93%.

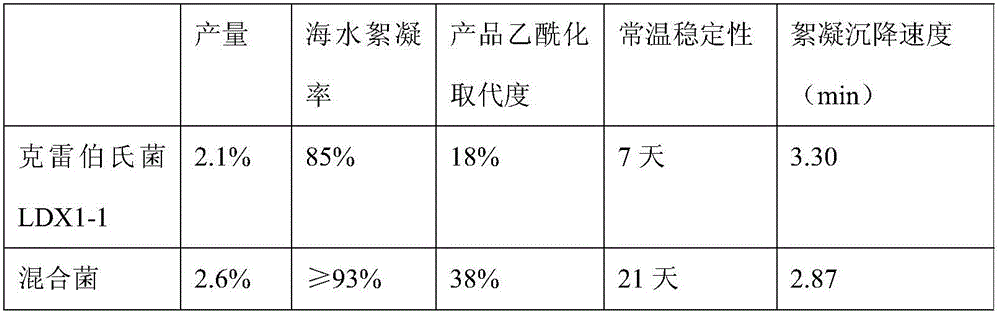

[0047] The flocculant was prepared by single-bacteria fermentation using Klebsiella LDX1-1 (using the method in Example 2 of patent application 201510656846.5) for comparison, and the results are shown in Table 1.

[0048] Table 1 The present invention is compared with the product effect of Klebsiella LDX1-1 single bacterium fermentation

[0049]

[0050] As can be seen from Table 1: the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com