Beryllium copper alloy, copper bush for amorphous and/or nano crystal strip production equipment and preparation method

A technology for beryllium copper alloy and production equipment, which is applied in the field of copper sleeve and preparation for production equipment of beryllium copper alloy and amorphous and/or nanocrystalline strip, can solve the problems of unsatisfactory thermal conductivity, strength and hardness, etc., Achieve significant social benefits, save materials, and reduce losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

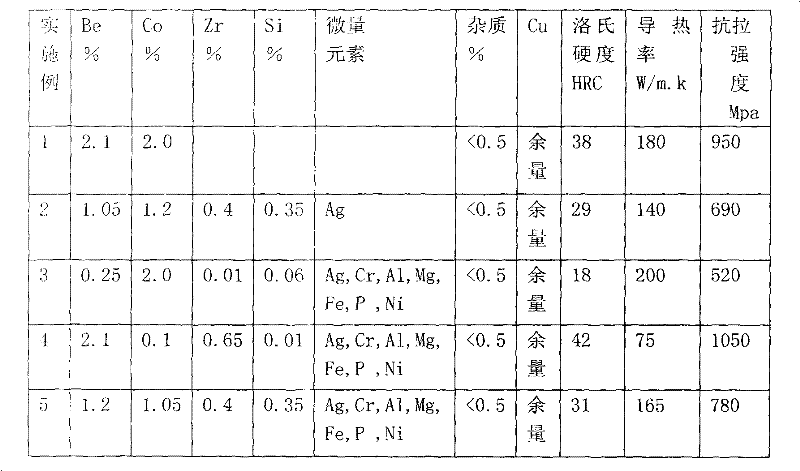

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below through specific examples.

[0021] The present invention is a beryllium-copper alloy, which contains elements Be and Co in copper, takes advantage of the interaction of alloy elements, and prepares high-strength and high-thermal-conductivity conforming amorphous and nanocrystalline ribbon production equipment through the following preparation method Beryllium copper alloy material with copper sleeve.

[0022] A preparation method of a beryllium-copper alloy copper sleeve is as follows:

[0023] (1) Smelting: prepare raw materials and accurately weigh them, and smelt them at a temperature of 1250-1350°C;

[0024] (2) Casting: pour the smelted beryllium-copper alloy into ingots or slabs, and control the pouring temperature at 1000-1150°C;

[0025] (3) Hot forging: Hot forging the billet at a temperature range of 600-910°C, and the hot forging reduction rate is ≥ 20%;

[0026] (4) Heat treatment: The heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com