Transparent conductive laminated body with visible adjustment layers

A transparent conductive layer, transparent conductive technology, applied to the conductive layer, oxide conductor, non-metallic conductor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

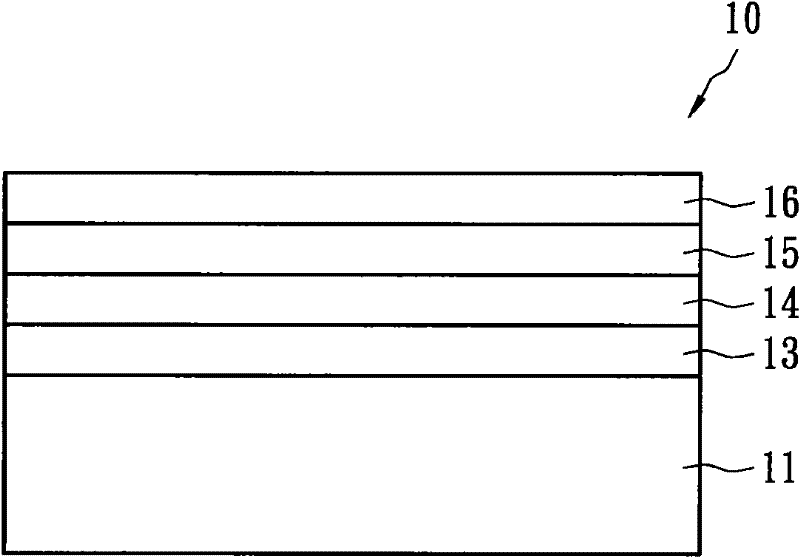

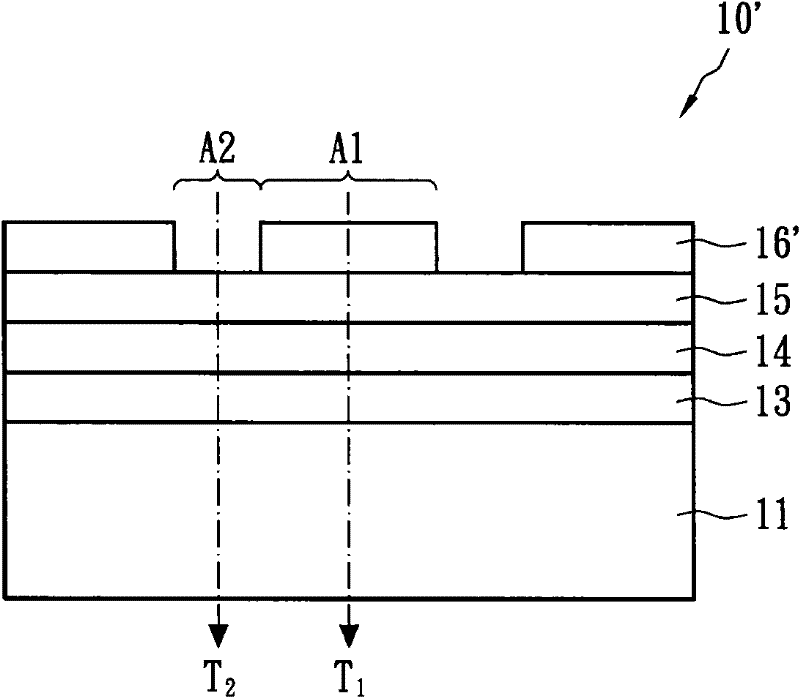

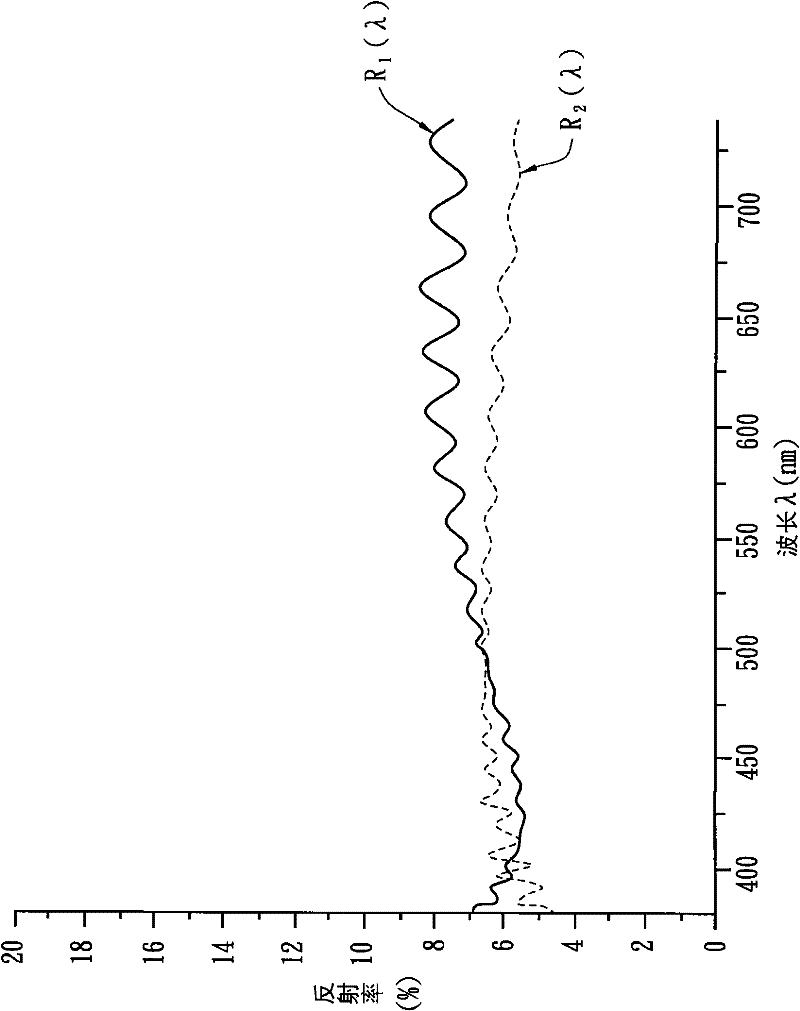

[0051] The embodiment of the present invention discussed below selects a polyethylene terephthalate (PET) substrate with a double-sided hardening treatment, its refractive index is about 1.43, and its thickness is 135 μm. The first visible light adjustment layer is wet-coated. The second visible light adjustment layer, the third visible light adjustment layer, the transparent conductive layer and the intermediate layer are formed by dry sputtering. Wherein the first visible light adjustment layer is Silicon-fluorine (fluorine) copolymer resin, and the second visible light adjustment layer is TiO 2 , the third visible light adjustment layer is SiO 2 , the transparent conductive layer is ITO, and the intermediate layer is SiOx. Comparative example is to select the polyethylene terephthalate (PET) base material that has double-sided hardening treatment, and its refractive index is about 1.43, and thickness is 135 μ m, the first buffer layer, the second buffer layer, and transpar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

| Optical thickness | aaaaa | aaaaa |

| Physical thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com