Blueberry pulp juice drink and preparation method thereof

A technology of blueberry fruit and blueberry, which is applied in food preparation, application, food science, etc., to achieve the effect of good absorption, pure taste and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

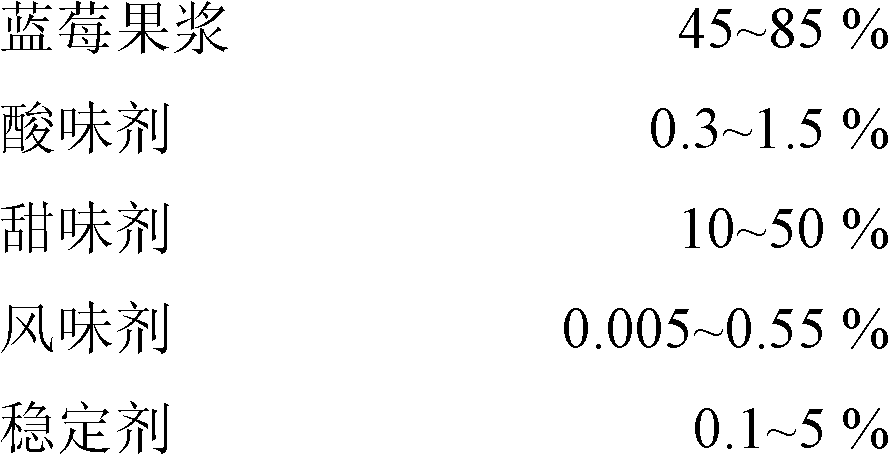

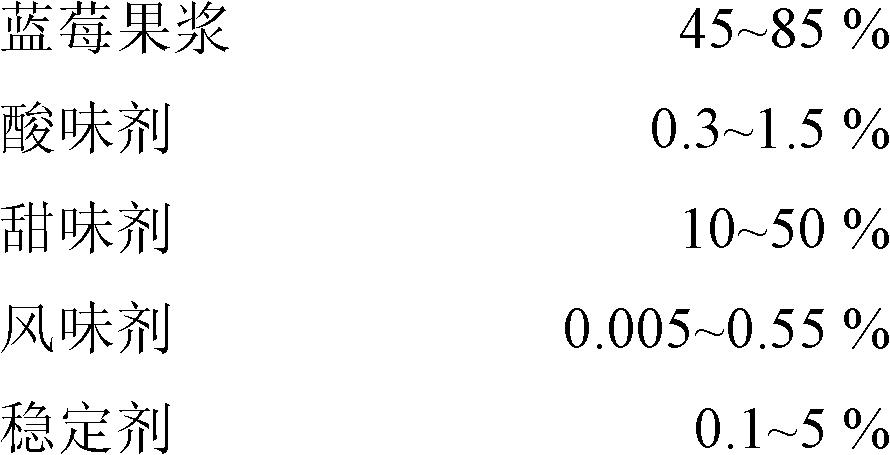

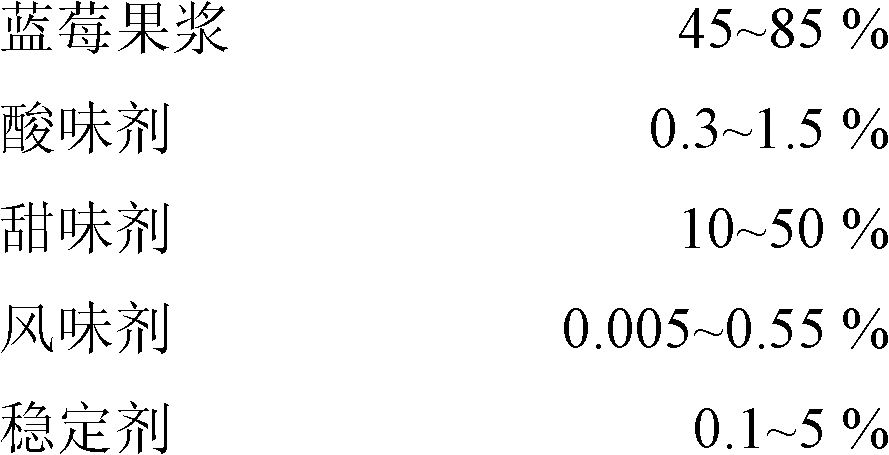

Method used

Image

Examples

Embodiment 1

[0034] Take 1000 kilograms of blueberries; sort the raw blueberries and rinse them with water; add 2000 kilograms of drinking water to crush the blueberries and make a pulp to make 2960 kilograms of blueberry pulp; 16 kilograms of citric acid; 560 kilograms of sucrose; 0.28 ethyl maltol kg; 3.0 kg of pectin; 3.0 kg of agar melted and pumped into the blending tank, adding 2100 kg of drinking water and fully mixing; then through colloid grinding, the blueberry pulp particle size is less than 0.1 mm; homogeneous pressure is 20MP; degassing; 121 ℃ instantaneous sterilization; 80 ℃ hot filling; capping; cooling to 20 ℃; packaging is the finished product of blueberry pulp juice drink.

Embodiment 2

[0036] Take 10,000 kg of blueberries; sort the raw blueberries and rinse them with water; add 50,000 kg of drinking water to crush the blueberries and beat them to make 59,900 kg of blueberry pulp; add 810 kg of malic acid; 16,200 kg of fructose syrup; 400 kg of maltol kg; 400 kg of xanthan gum; 400 kg of carrageenan melted and pumped into the blending tank, adding 40,000 kg of drinking water and fully mixing; then through colloid grinding, the blueberry pulp particle size is less than 0.1 mm; homogeneous pressure is 50MP; degassing ; Instant sterilization at 121°C; hot filling at 90°C;

Embodiment 3

[0038] Take 100 kilograms of blueberries; sort the raw blueberries and rinse them with water; add 300 kilograms of drinking water to crush the blueberries and beat them to make 396 kilograms of blueberry pulp; add 2.4 kilograms of tartaric acid; 72 kilograms of sucrose; 0.24 kilograms of ethyl maltol ; 4.8 kg of gelatin; 4.8 kg of sodium hydroxymethylcellulose melted and pumped into the blending tank, adding 450 kg of drinking water and fully mixing; then through colloid grinding, the blueberry pulp particle size is less than 0.1 mm; homogenization pressure is 35MP; 121°C instant sterilization; 85°C hot filling; capping; cooling to 25°C; packaging is the finished product of blueberry pulp juice drink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com