Solar battery material SnS nanocrystal synthesized under conditions of high temperature and liquid phase by non-injection method

A technology of solar cell and liquid phase synthesis, which is applied in the direction of circuits, electrical components, non-metal elements, etc., to achieve the effect of simple operation process, environmental friendliness and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

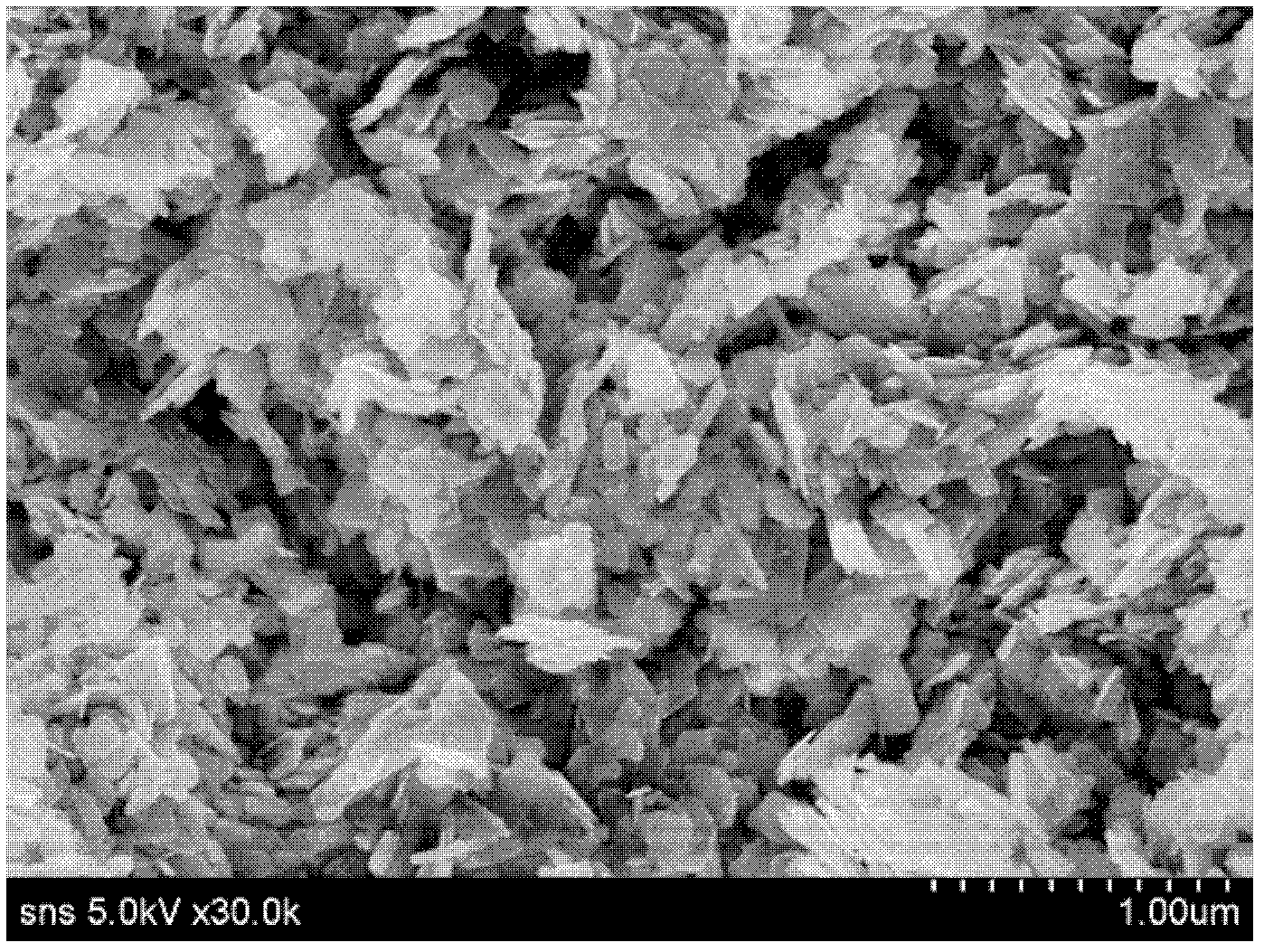

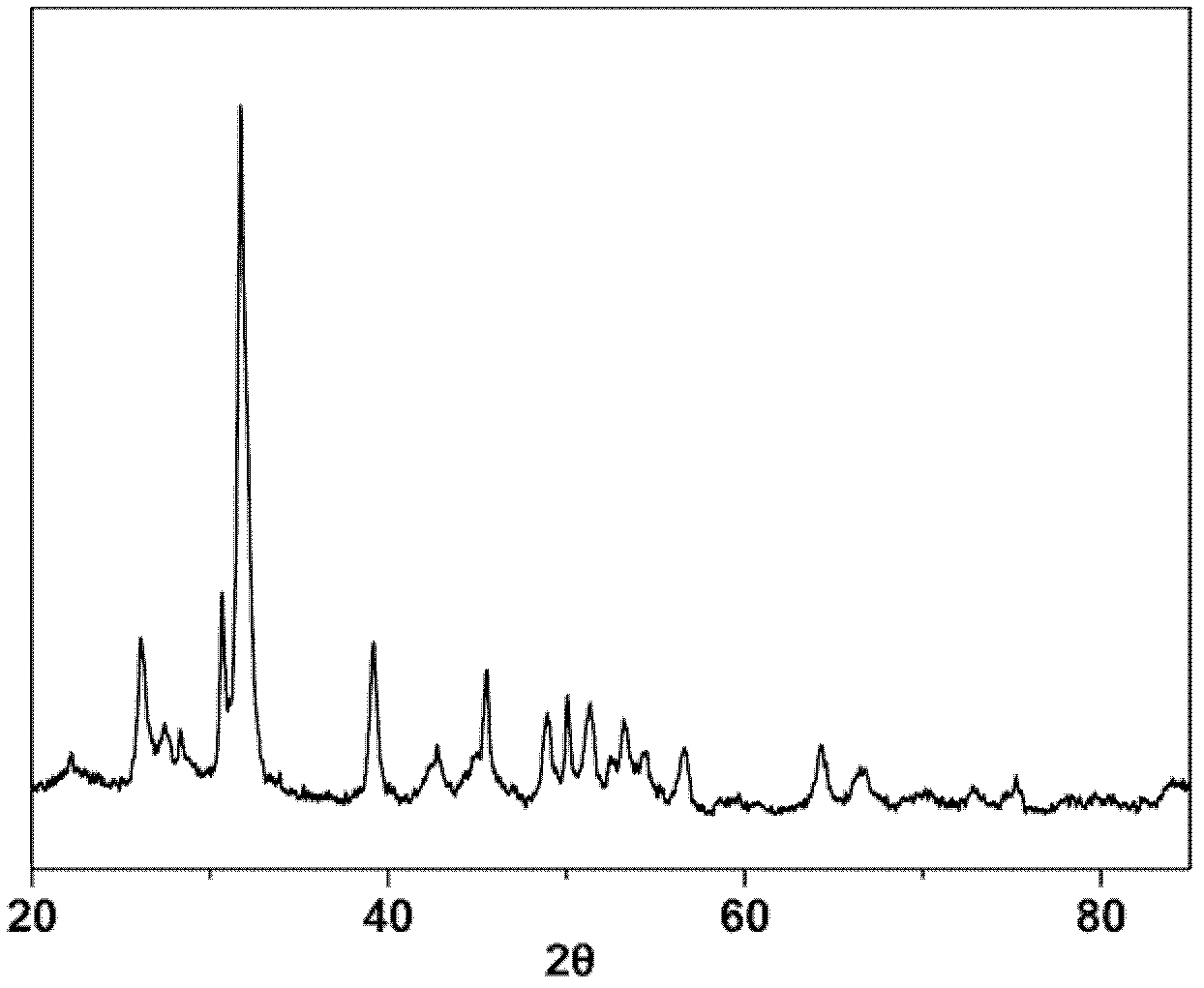

Embodiment 1

[0021] Synthesis of nanocrystals: Measure 15mL oleylamine into a round-bottomed flask, add 0.2g tin diethyldithiocarbamate under magnetic stirring, and stir evenly, then slowly raise the temperature to 300°C under nitrogen protection, and keep the temperature stable The reaction was carried out for 20 min, and then naturally cooled to room temperature. Wash and separate the obtained SnS precipitate with excess ethanol to obtain SnS nanocrystals.

Embodiment 2

[0023] Synthesis of nanocrystals: Measure 15mL of oleic acid into a round bottom flask, add 0.4g tin diethyldithiocarbamate under magnetic stirring, and stir evenly, then slowly raise the temperature to 320°C under nitrogen protection, and keep the temperature stable The reaction was carried out for 30 min, and then naturally cooled to room temperature. Wash and separate the obtained SnS precipitate with excess ethanol to obtain SnS nanocrystals.

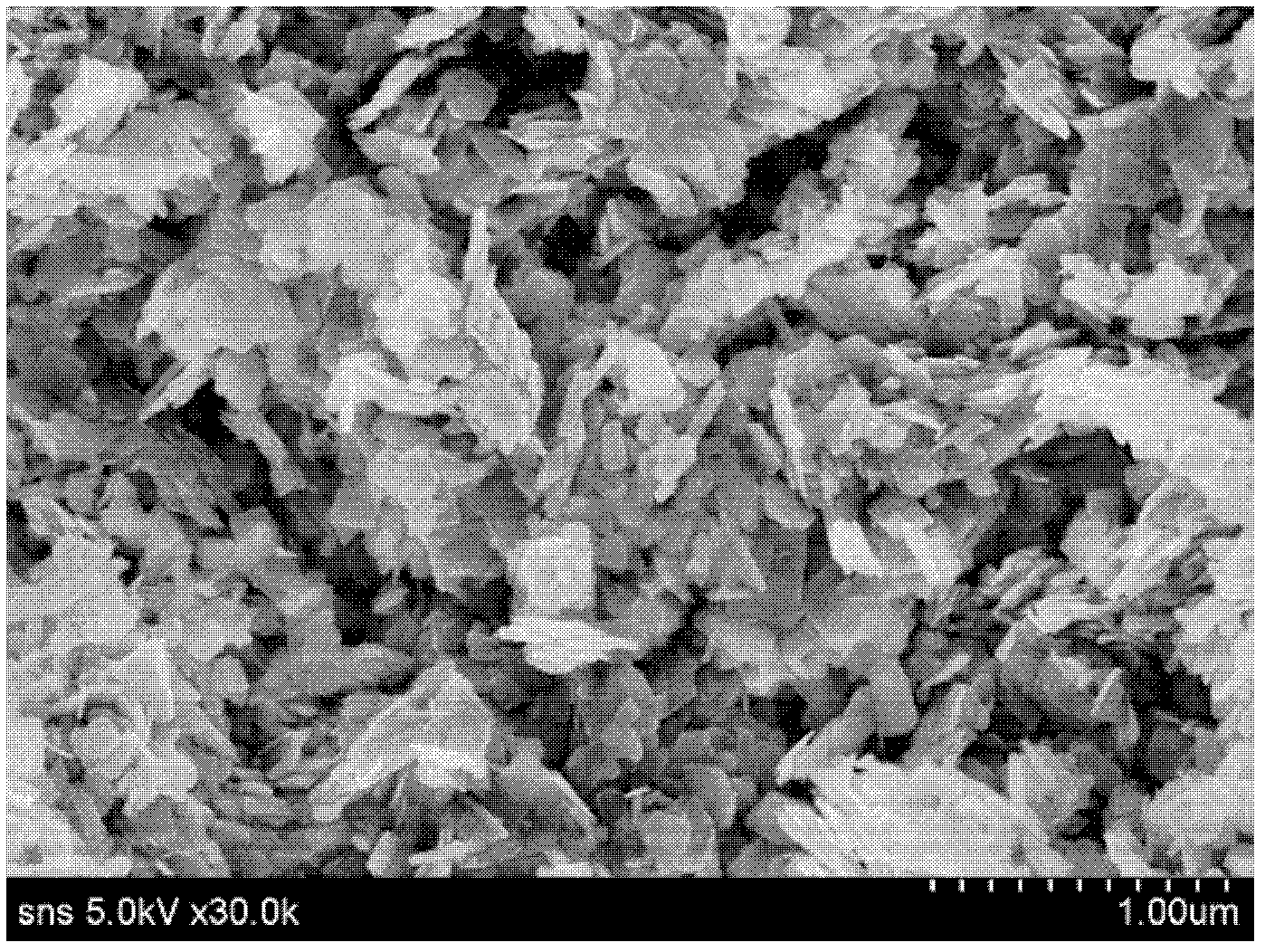

Embodiment 3

[0025] Synthesis of nanocrystals: Measure 15mL of octadecene into a round-bottomed flask, add 0.6g of tin diethyldithiocarbamate under magnetic stirring, and stir evenly, then slowly raise the temperature to 340°C under nitrogen protection, and keep the temperature The reaction was stabilized for 50 min, and then naturally cooled to room temperature. Wash and separate the obtained SnS precipitate with excess ethanol to obtain SnS nanocrystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com