Thermochromic vanadium dioxide powder and preparation method thereof

A vanadium dioxide, thermochromic technology, applied in vanadium oxide, chemical instruments and methods, color-changing fluorescent materials, etc., can solve the difficulty of adding vanadium dioxide single-phase crystalline powder, cannot fully meet the preparation requirements, and affect the reaction products. Chemical ratio and other issues, to achieve the effects of environmental protection, stable chemical state, improved comfort and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of the thermochromic vanadium dioxide powder provided in this embodiment is to weigh vanadyl oxalate hydrate (VOC 2 O 4 ·nH 2 O) 1.602 g, ammonium metavanadate (NH 4 VO 3 ) 0.882g, put it into a 100ml polytetrafluoroethylene-lined hydrothermal reaction vessel at the same time with 50g of ice and seal it immediately, put it in a drying oven and heat it up to 270°C and keep it warm for 12 hours to take out. The reaction product was isolated by filtration and dried in an oven at 70°C for 12 hours to obtain the defined microparticles.

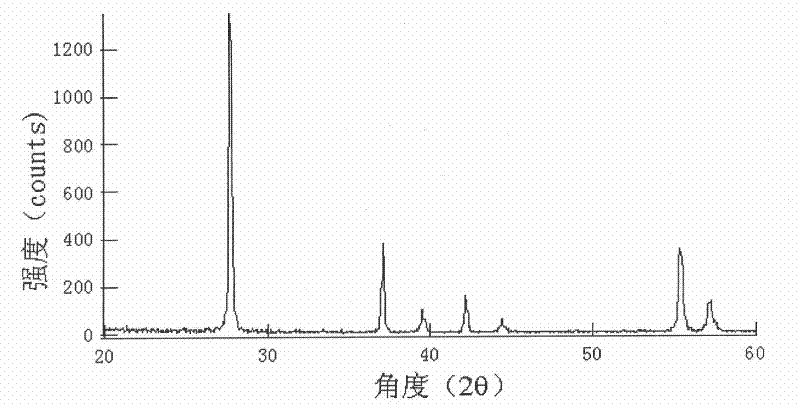

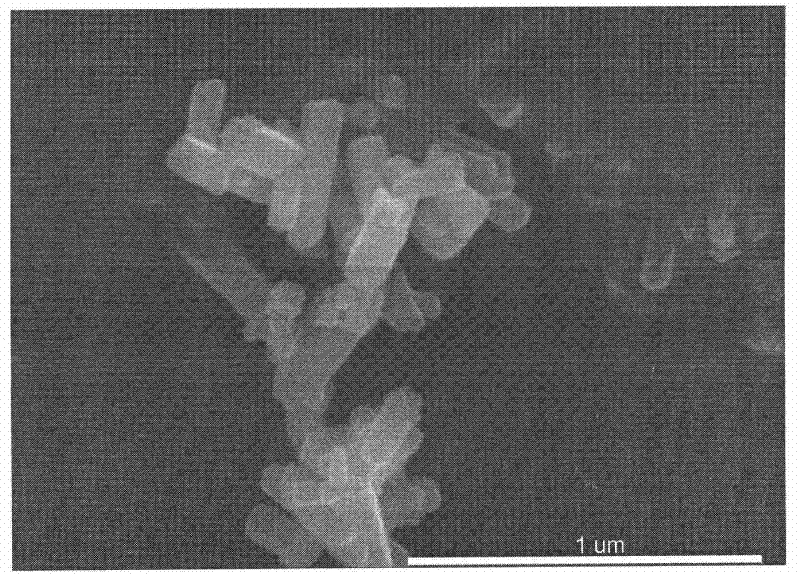

[0027] The powder X-ray diffraction analysis results of the determined particles are as follows figure 1 As shown, it is a single-phase crystal of vanadium dioxide with rutile structure; the powder electron microscope observation results of the determined particles are as follows figure 2 As shown, the single-phase crystalline powder of vanadium dioxide is monodispersed, the morphology is rod-like, and the minimu...

Embodiment 2

[0031] The preparation method of the thermochromic vanadium dioxide powder provided in this embodiment is to weigh vanadyl oxalate hydrate (VOC 2 O 4 ·nH 2 O) 0.830 g, ammonium metavanadate (NH 4 VO 3 ) 0.212 g, vanadium pentoxide (V 2 O 5 ) 0.335g, put it into a 25ml polytetrafluoroethylene-lined hydrothermal reaction vessel at the same time with 10g of ice and seal it immediately, and put it in a drying oven and heat it up to 220°C and take it out after keeping the temperature for 120 hours. After separation by filtration and drying at 70°C for 12 hours, the specified microparticles were obtained.

[0032] The powder X-ray diffraction analysis result of the obtained particles is a single crystal phase of vanadium dioxide with rutile structure, which is an aggregate and has a rod-like shape.

Embodiment 3

[0034] The preparation method of the thermochromic vanadium dioxide powder provided in this example is different from Example 1 in that: adding tungstic acid (H 2 WO 4 ) 0.035 g, the powder X-ray diffraction analysis result of the obtained particles is a vanadium dioxide single crystal phase with a rutile structure, which is an aggregate and has a rod-like appearance.

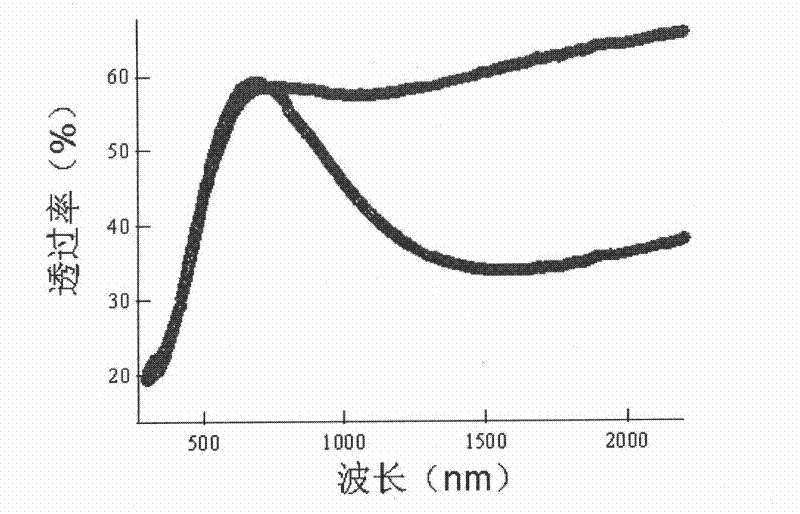

[0035] The obtained powder was uniformly dispersed on the transparent resin double-sided tape, and the double-sided tape was attached to a glass test piece with a thickness of 1 mm to obtain a dimming glass. The spectral transmission spectrum of the dimming glass was measured. The phase transition temperature of the high powder was determined to be 35°C from the temperature change of the near-infrared (wavelength 1 μm) transmittance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com