Production process and equipment for hollow glass microbeads

A technology of hollow glass microspheres and production process, which is applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of complex production process, poor chemical stability, low compressive strength, etc., and achieve good chemical stability, The effect of low cost and meeting performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

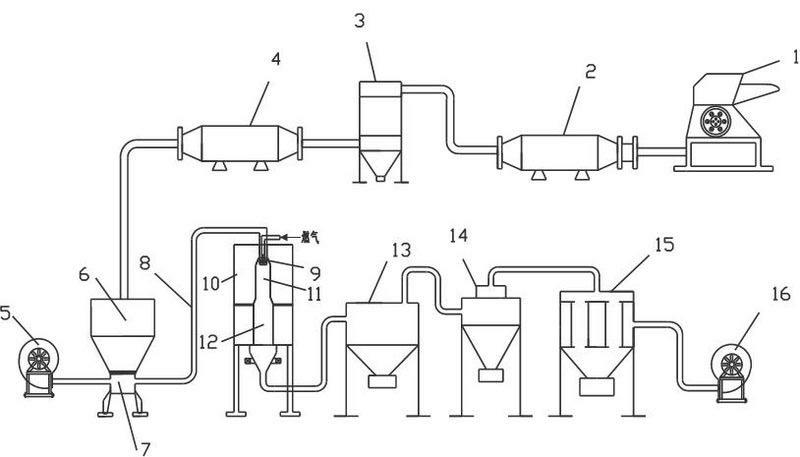

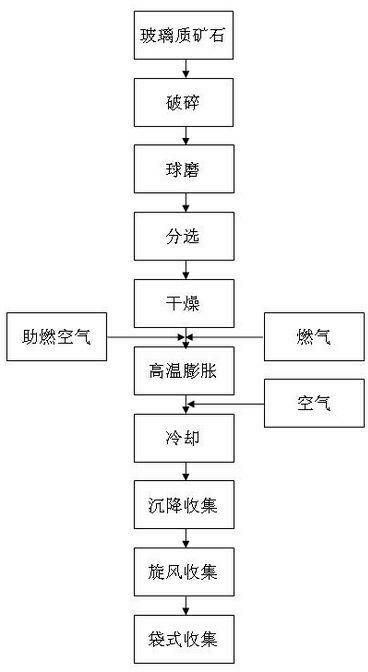

[0032] The glassy minerals are crushed in the crusher 1 and then enter the pulverizer 2. The pulverized powder passes through the classifier 3 to sort out the powder with a particle size of 5 μm, and then enters the dryer 4 at a drying temperature of 300°C. , remove the free water in the powder, and the bound water content is 2wt%.

[0033] The powder enters the hollow glass microsphere expansion furnace 10 through pneumatic conveying, and passes through the high temperature expansion zone 11 and heat preservation and tempering zone 12 of the hollow glass microsphere expansion furnace 10 from top to bottom. The expansion temperature is 1000°C, and the heat preservation and tempering temperature is 800°C. The hollow glass microspheres go down with the high-temperature airflow, mixed with the controllable cooling air to cool and form, and finally the high-performance hollow glass microspheres are obtained through the collection component. The obtained hollow glass microspheres h...

Embodiment 2

[0038] The glassy minerals are crushed in the crusher 1 and enter the pulverizer 2. The pulverized powder passes through the classifier 3 to sort out the powder with a particle size of 200 μm, and then enters the dryer 4 with a drying temperature of 750°C. , remove the free water in the powder, and the bound water content is 0.1wt%.

[0039] The powder enters the hollow glass microsphere expansion furnace 10 through pneumatic conveying, and passes through the high temperature expansion zone 11 and heat preservation and tempering zone 12 of the hollow glass microsphere expansion furnace 10 from top to bottom. The expansion temperature is 1400°C, and the heat preservation and tempering temperature is 1150°C. The hollow glass microspheres go down with the high-temperature airflow, mixed with the controllable cooling air to cool and form, and finally the high-performance hollow glass microspheres are obtained through the collection component. The obtained hollow glass microspheres...

Embodiment 3

[0044] The glassy minerals are crushed in the crusher 1 and enter the pulverizer 2, and the pulverized powder passes through the classifier 3 to sort out the powder with a particle size of 40 μm, and then enters the dryer 4, and the drying temperature is 400°C , remove the free water in the powder, the bound water content is 0.6wt%.

[0045] The powder enters the hollow glass microsphere expansion furnace 10 through pneumatic conveying, and passes through the high temperature expansion zone 11 and heat preservation and tempering zone 12 of the hollow glass microsphere expansion furnace 10 from top to bottom. The expansion temperature is 1250°C, and the heat preservation and tempering temperature is 900°C. The hollow glass microspheres go down with the high-temperature airflow, mixed with the controllable cooling air to cool and form, and finally the high-performance hollow glass microspheres are obtained through the collection component. The obtained hollow glass microspheres ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com