Processing assistant for expansion molding, vinyl chloride resin composition for expansion molding, and expansion molded body

A technology for vinyl chloride resin and foam molding, which is applied in the field of foam molding, can solve the problems of difficult foam molding, uneven foam cell structure, elongation characteristics, insufficient melting strength, etc., and achieves improved melting The effect of strength, excellent molding appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Add 230 parts of deionized water into a reactor equipped with a stirring device and a reflux condenser, further add 1.5 parts of dioctyl sodium sulfosuccinate, and replace the container with nitrogen. Then 0.15 parts of potassium persulfate and 100 parts of isobutyl methacrylate were added thereto, and the external temperature of the reactor was raised to 65° C. under stirring, and heated and stirred for 2 hours to complete polymerization and obtain latex.

[0059] The latex was cooled, and spray-dried under the conditions that the inlet temperature of the drying gas was 160° C. and the outlet temperature of the drying gas was 70° C. to obtain a polymer powder. Reduced viscosity of polymer (η sp / c) was 9.7. The obtained powder of the polymer (A) was used as a processing aid (B-1) for foam molding.

[0060] 15 parts of the obtained processing aid for foam molding (B-1) were mixed as follows, and the blending was completed at an internal temperature of 90° C. to obtain...

Embodiment 2~3、 comparative example 1~8

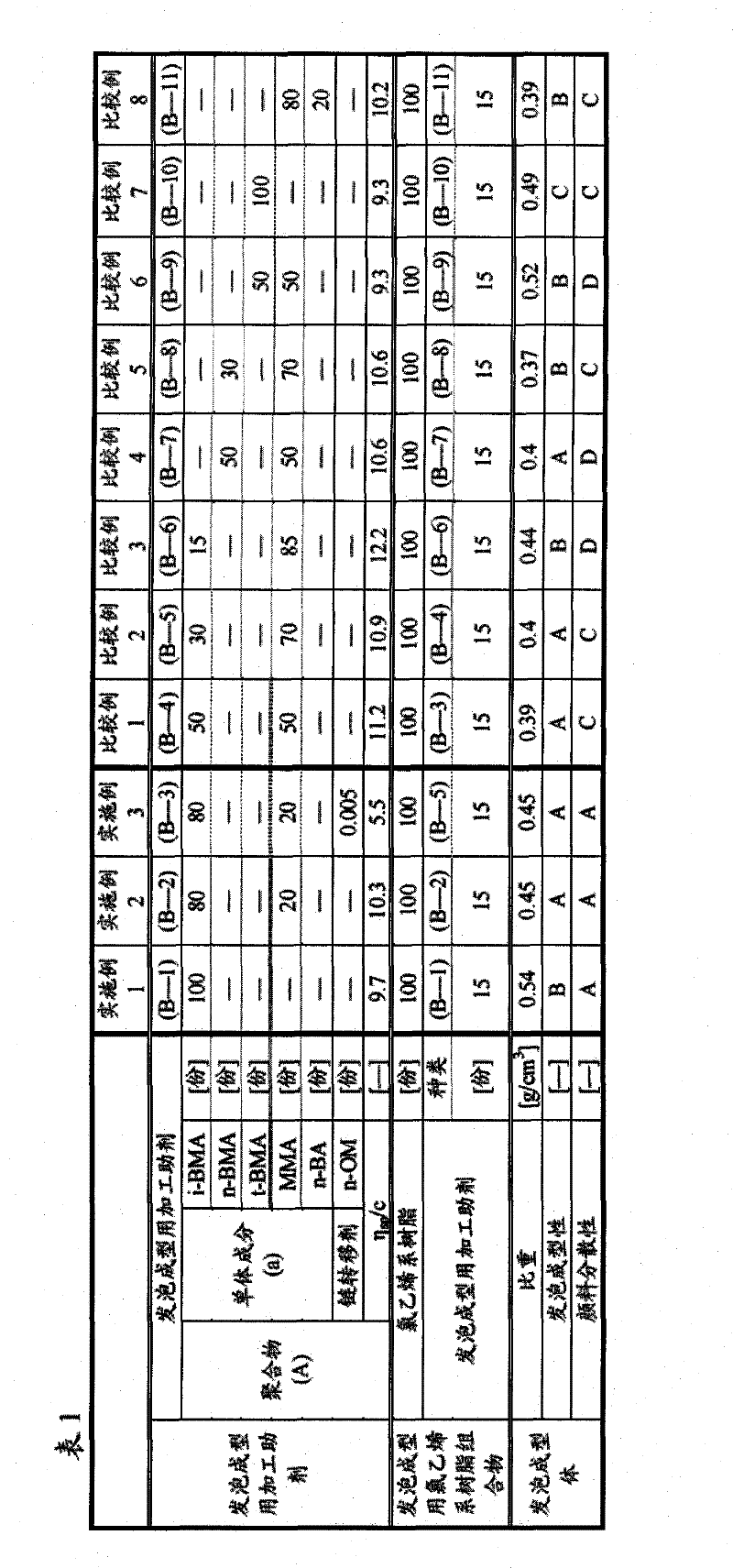

[0090] Except that the composition of the monomer components was changed to the ratio shown in Table 1, the same operation was carried out as in Example 1, and polymerization and spray drying were carried out to obtain polymer powder, a vinyl chloride resin composition for foam molding, and foam. Foam molding.

[0091] Table 1 shows the evaluation results of the foamed molded articles obtained in Examples 1 to 3 and Comparative Examples 1 to 8.

[0092]

[0093] The abbreviations in the table are as follows.

[0094] i-BMA: Isobutyl methacrylate

[0095] n-BMA: n-butyl methacrylate

[0096] t-BMA: tert-butyl methacrylate

[0097] MMA: methyl methacrylate

[0098] n-BA: Butyl acrylate

[0099] n-OM: n-octylthiol

[0100] As is clear from the results in Table 1, the use of a processing aid for foam molding containing a polymer (A) obtained by polymerizing a monomer component (a) containing 65% by mass or more of isobutyl methacrylate By performing foam molding, a molde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Long trail | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com