Patents

Literature

123 results about "Isobutylmethacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

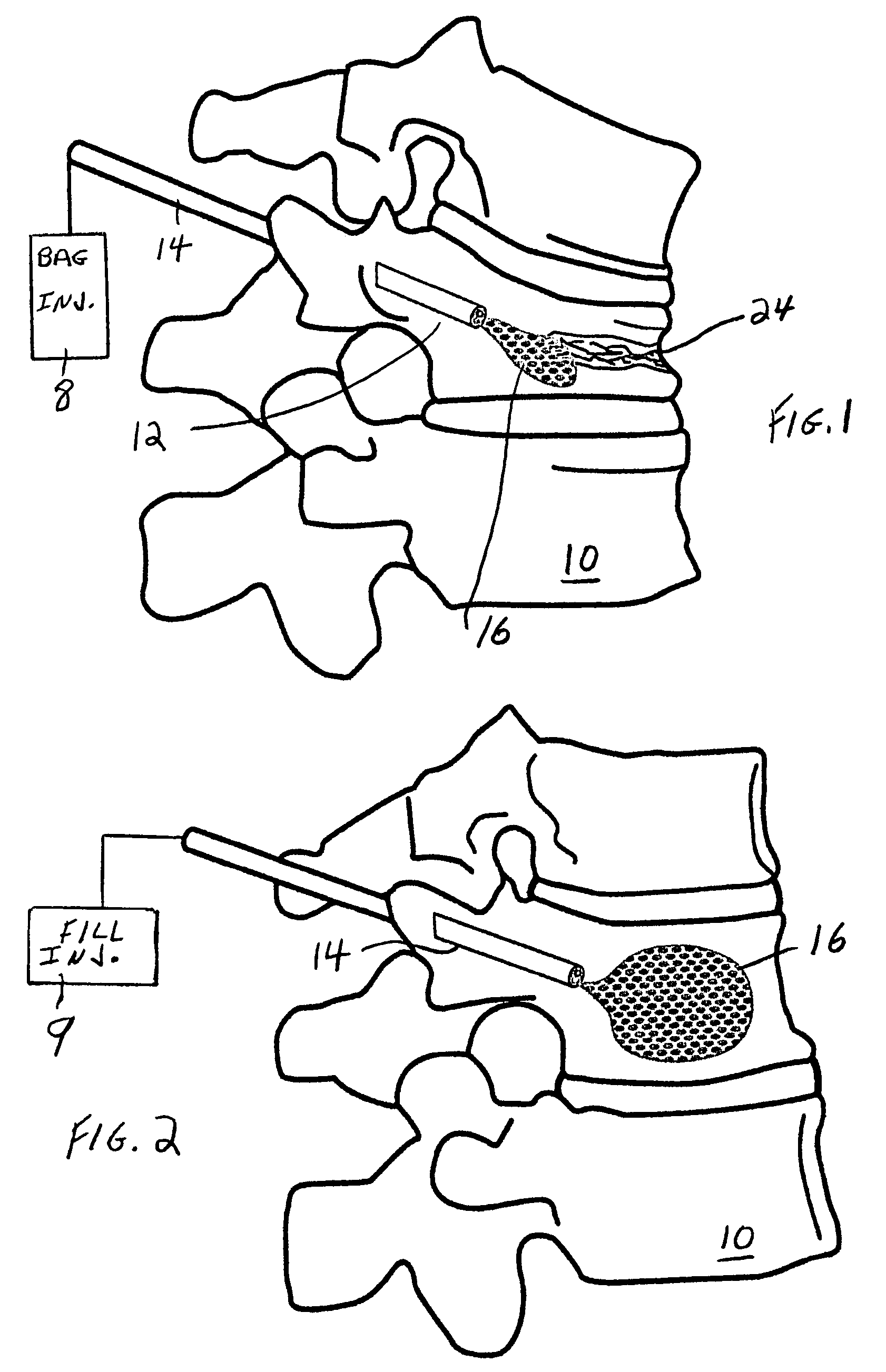

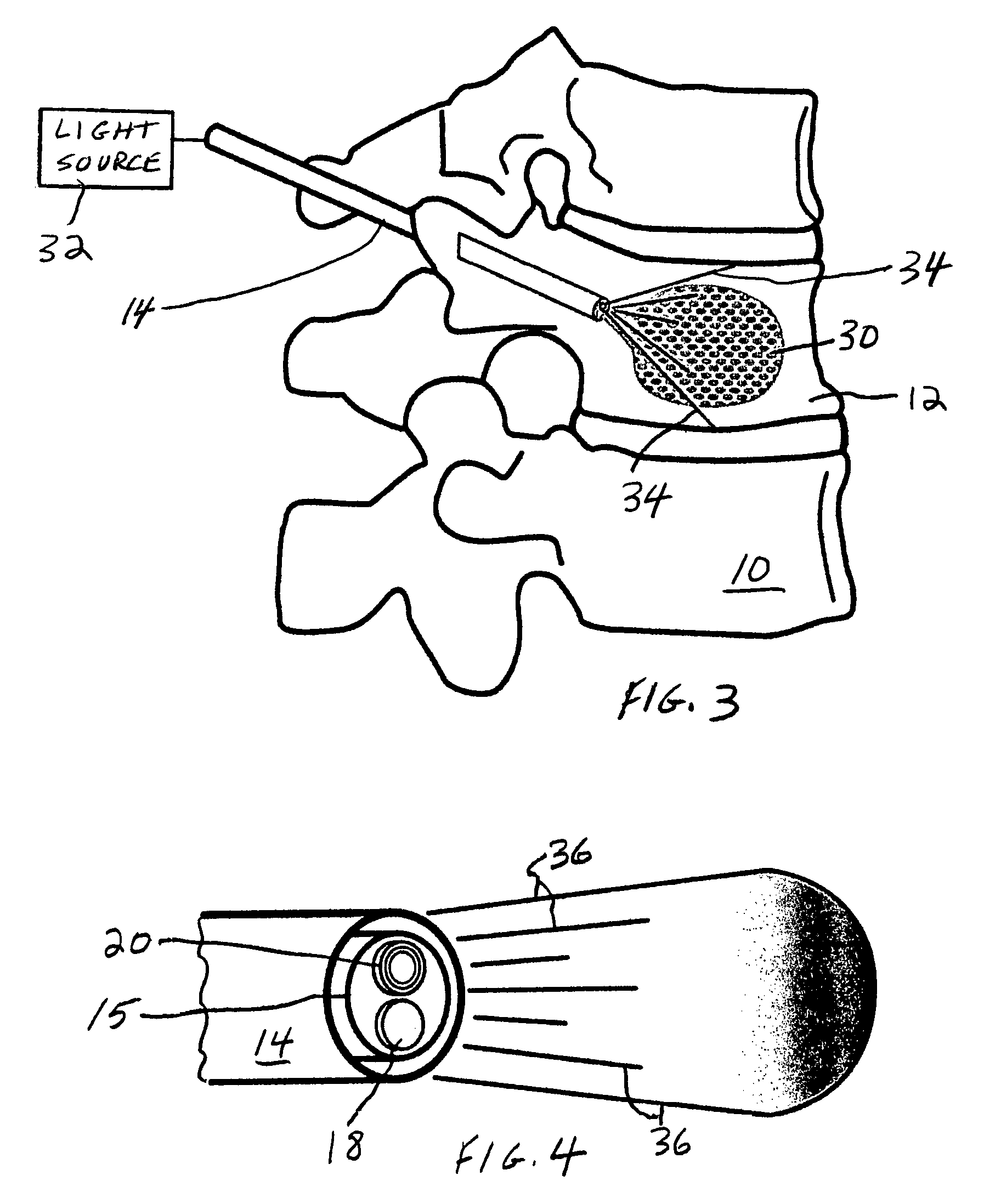

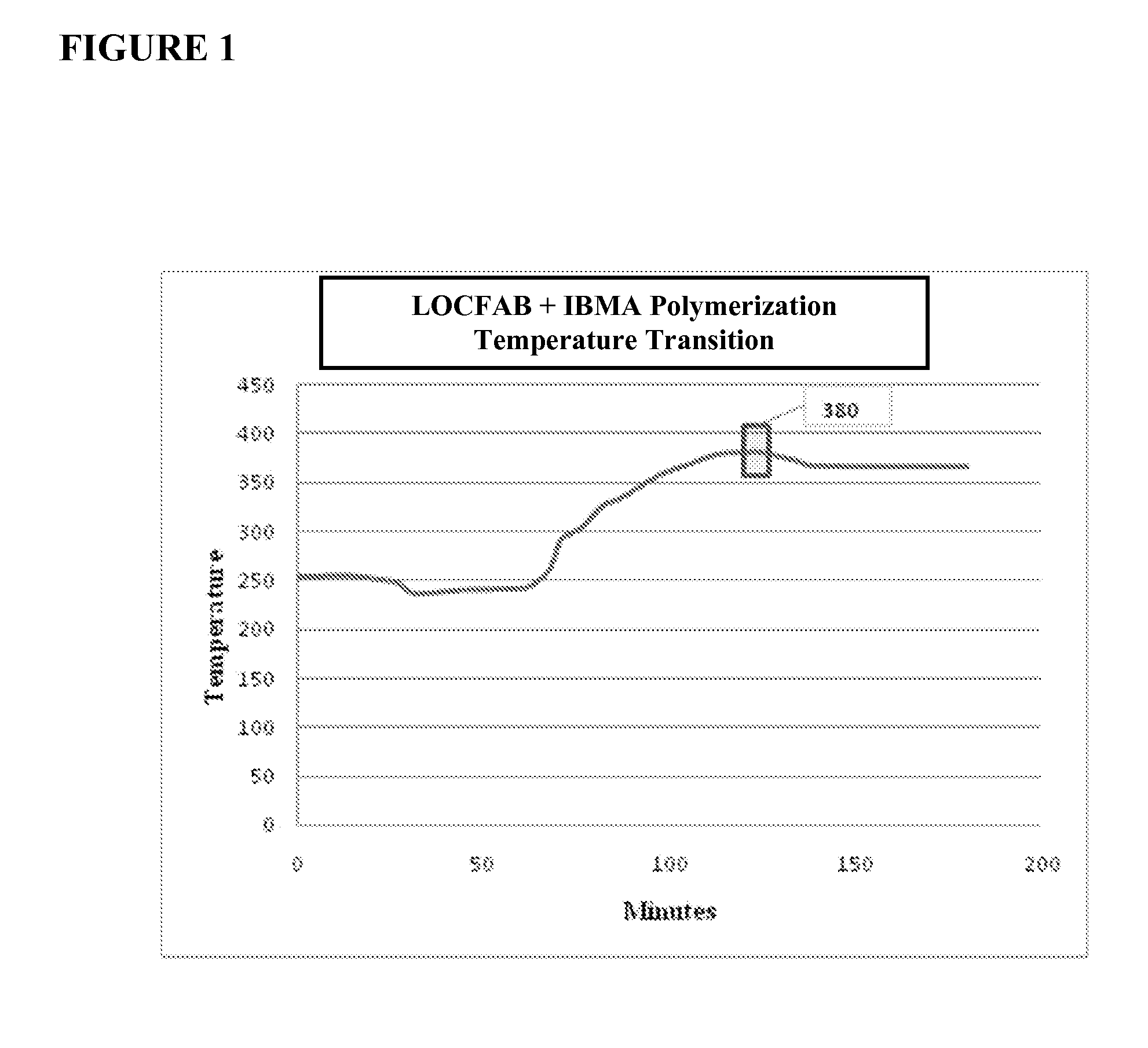

Spinal fill for disk surgery

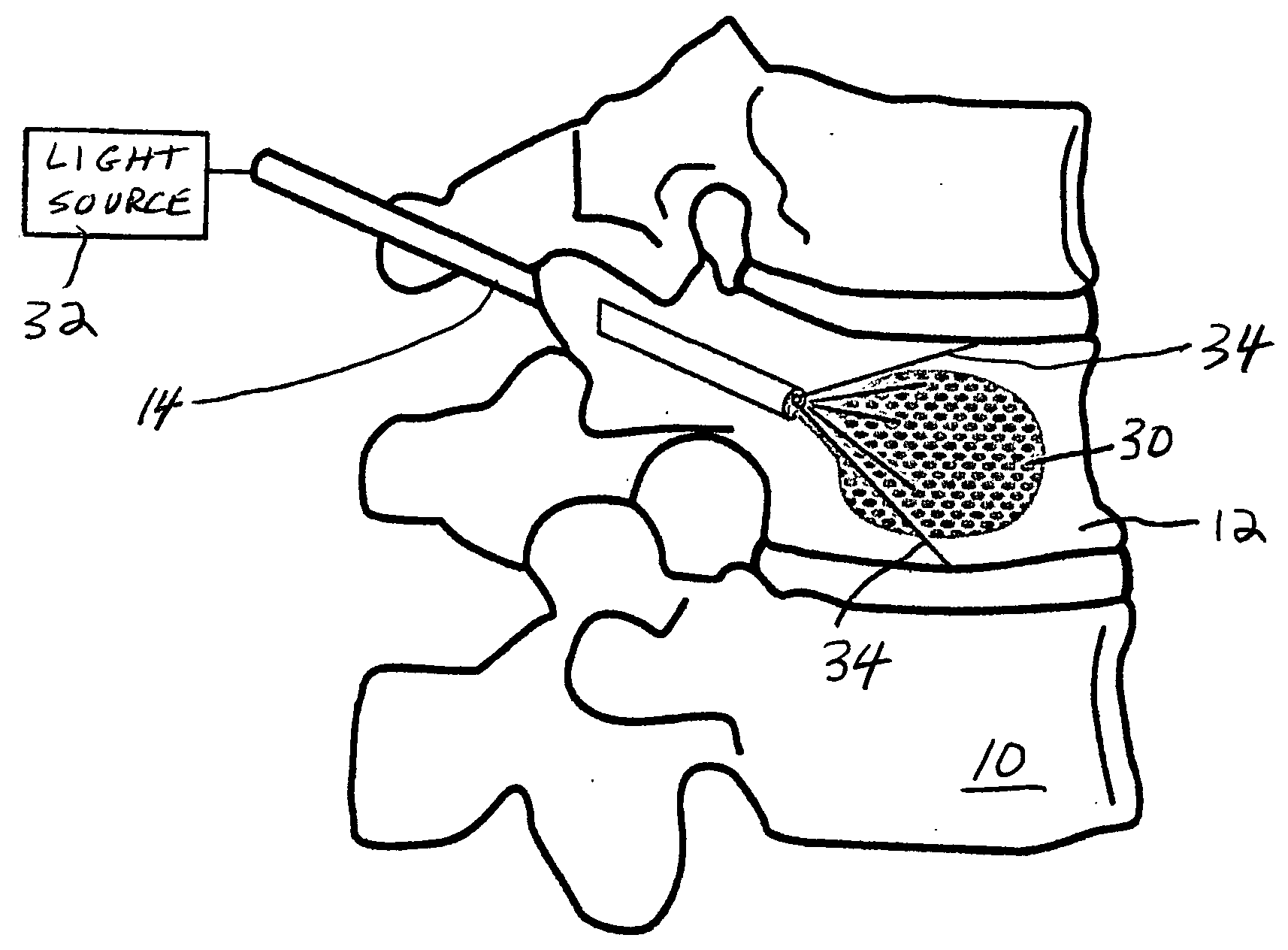

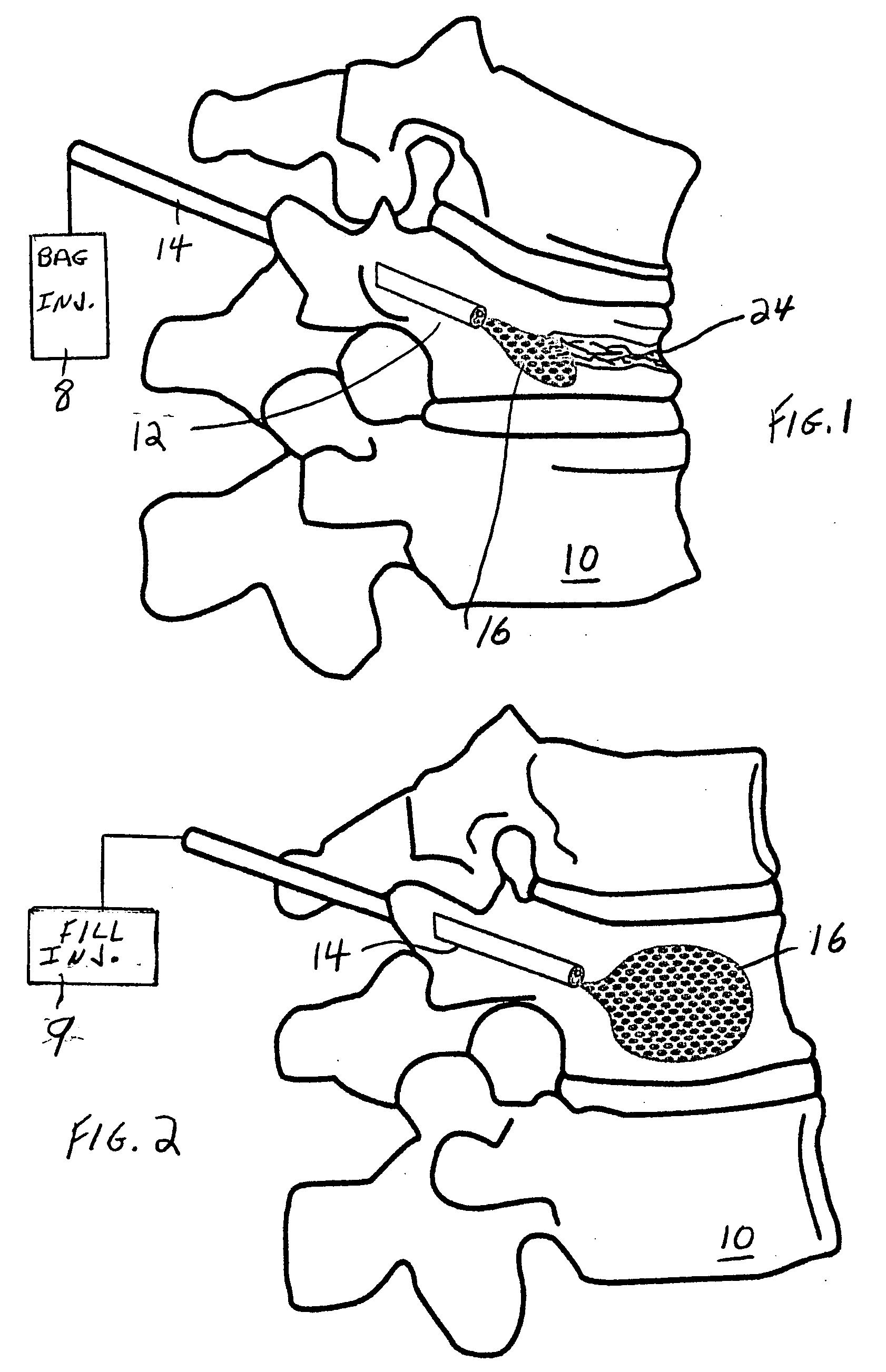

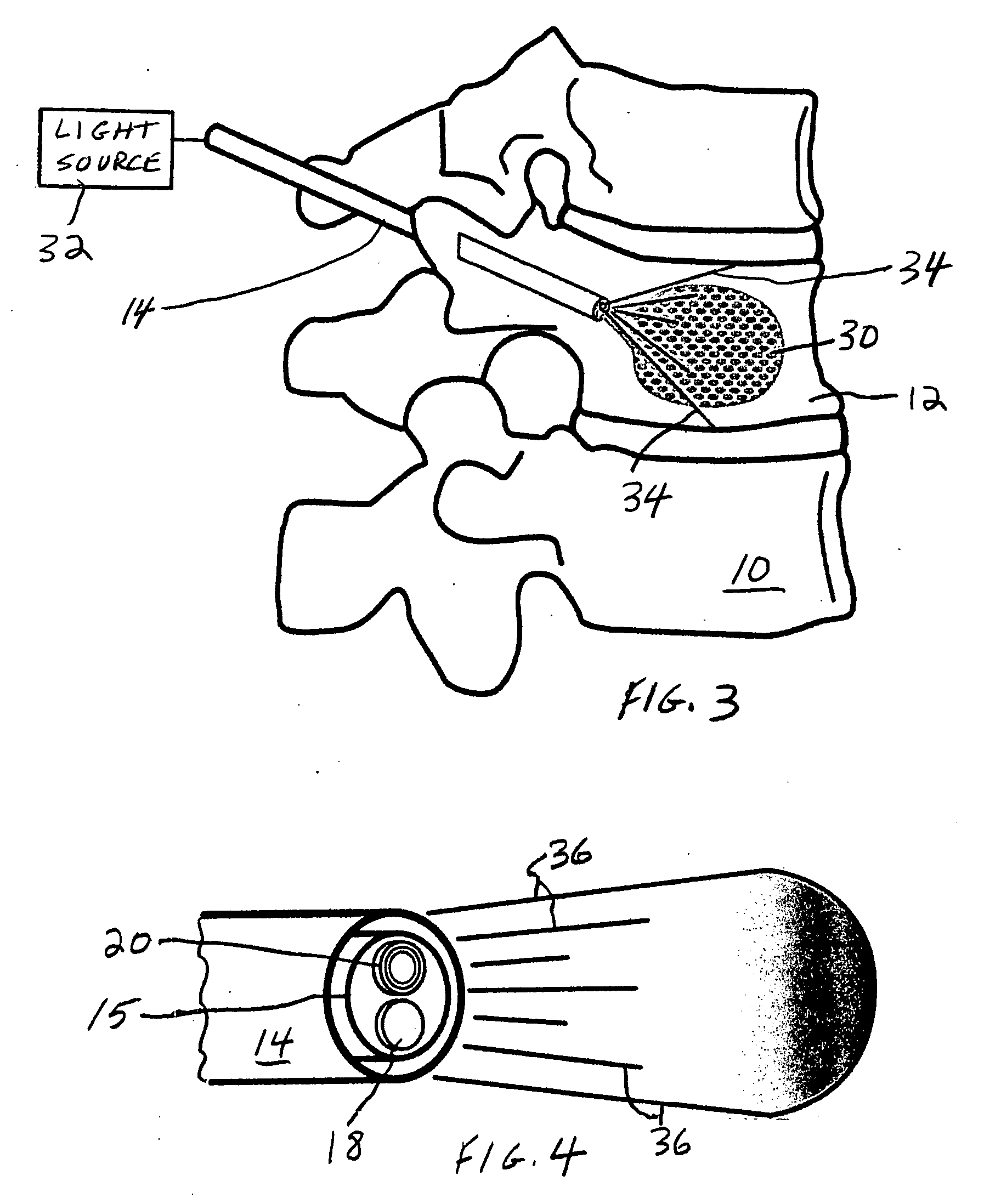

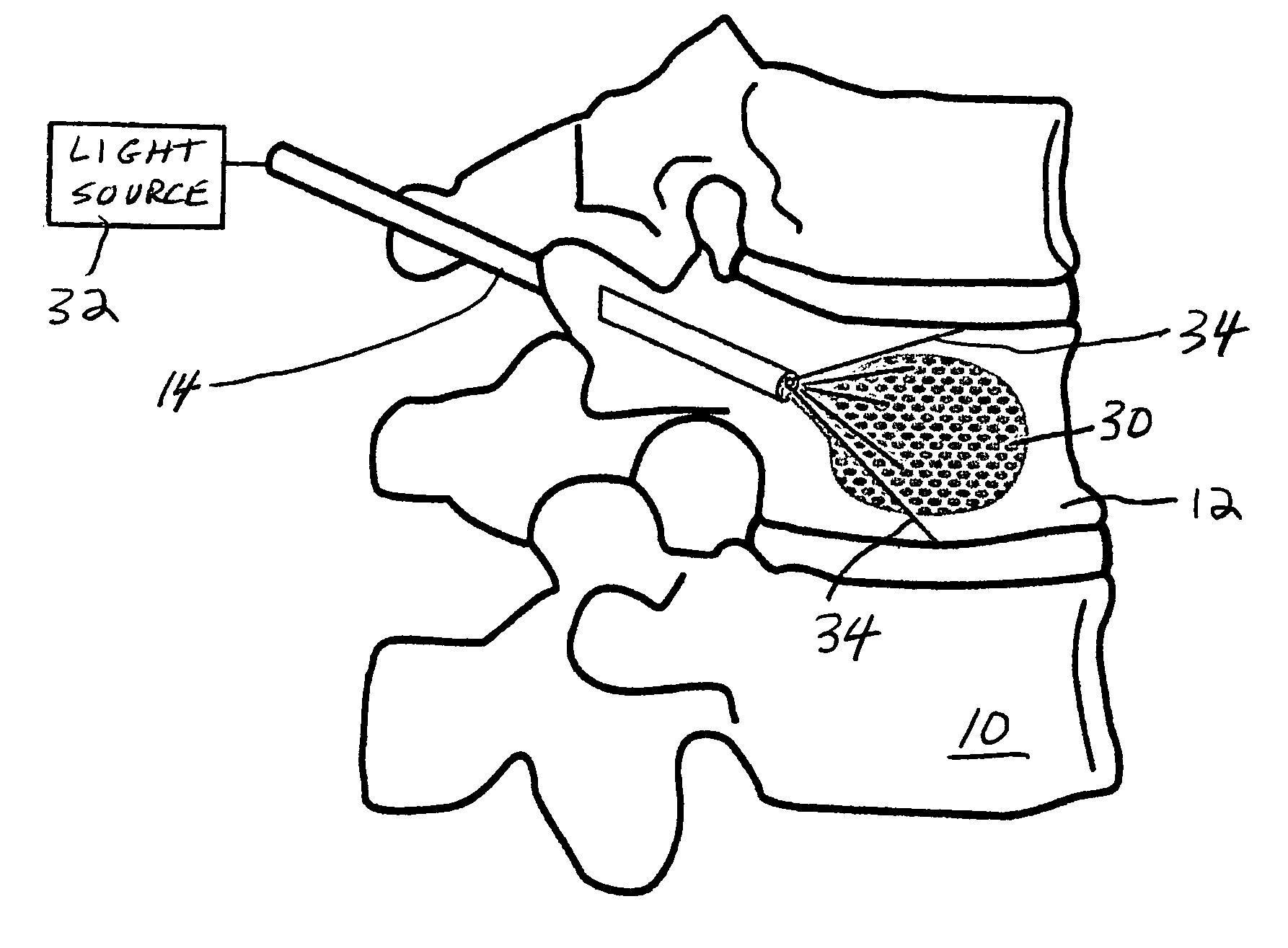

The invention is based on the use of polyisobutylmethacrylate instead of PMMA as an adhesive or spinal fill material for treating diseases of the spine. Polyisobutylmethacrylate has several advantages over PMMA, mainly less heat is developed during the in situ polymerization process. When using any spinal adhesive of fill material that is light activated, a tube can be used to transmit activating light to the light-activated adhesive or spinal polymerizable fill material at the surgical site. In addition, a mesh bag comprising optical fibers or similar light transmitting material can be employed to receive the injected light-activated fill, with the mesh bag, irradiated externally, for directing the light via the bag to the polymerizable fill.

Owner:ELLIQUENCE

Spinal fill for disk surgery

Owner:ELLIQUENCE

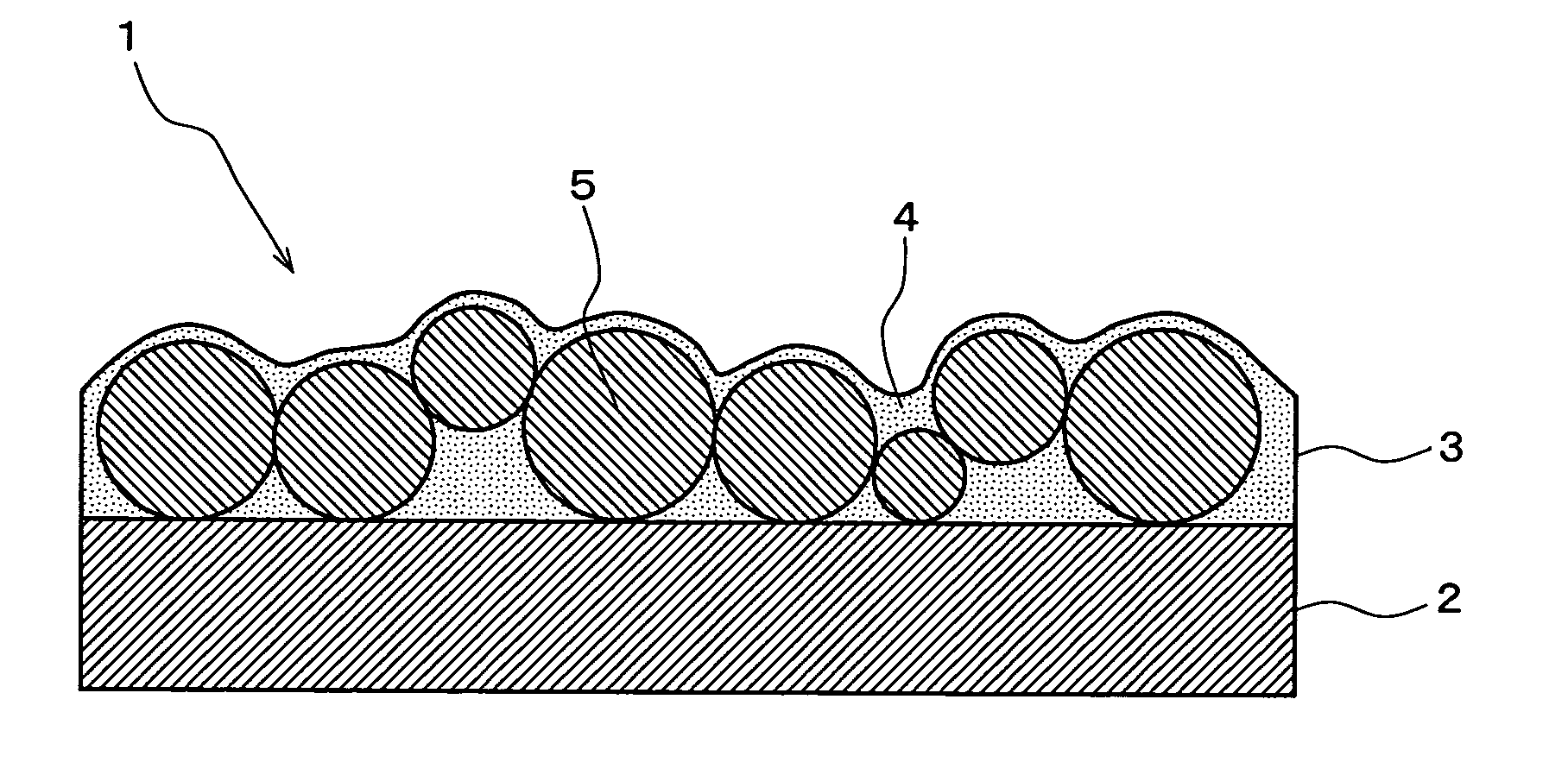

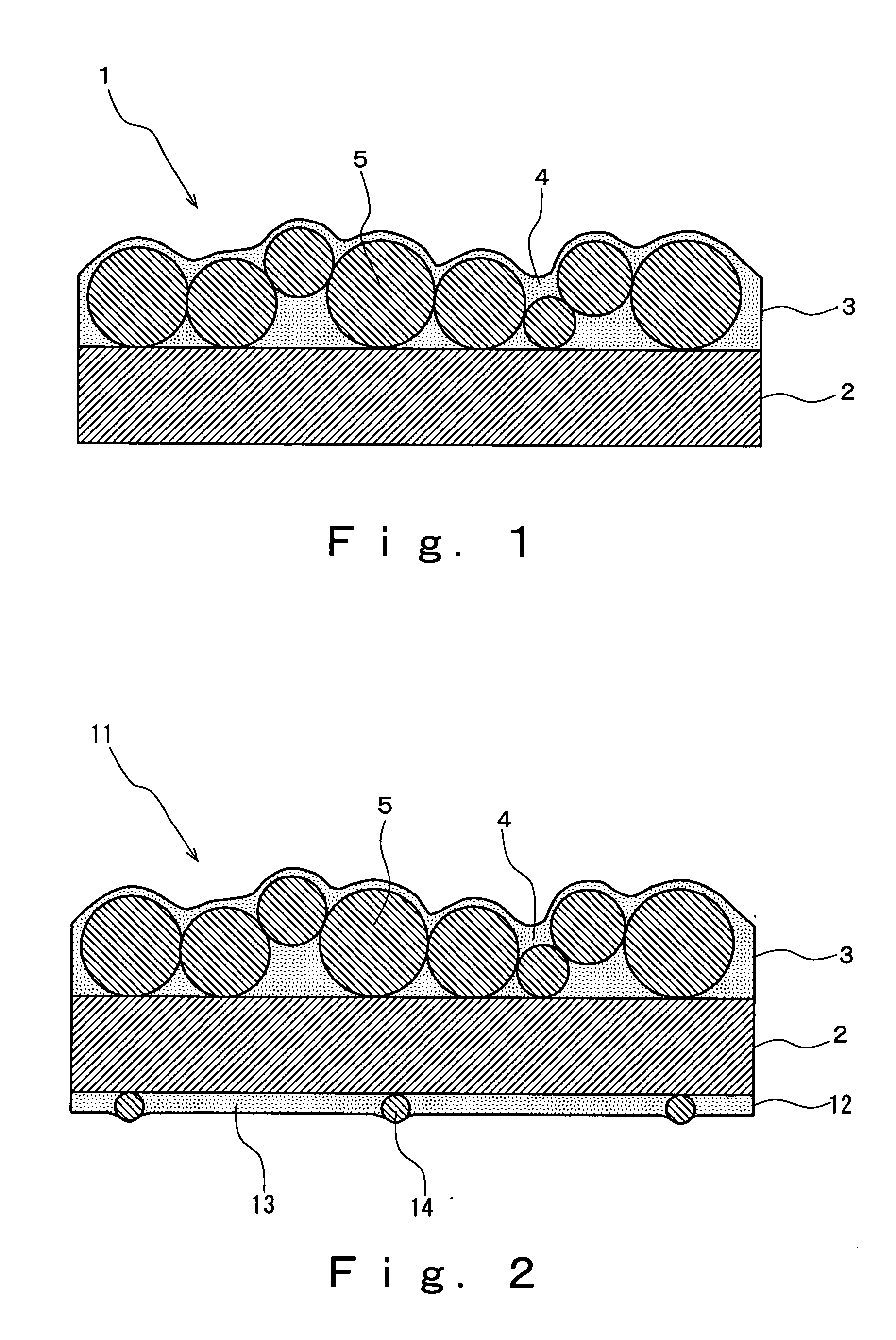

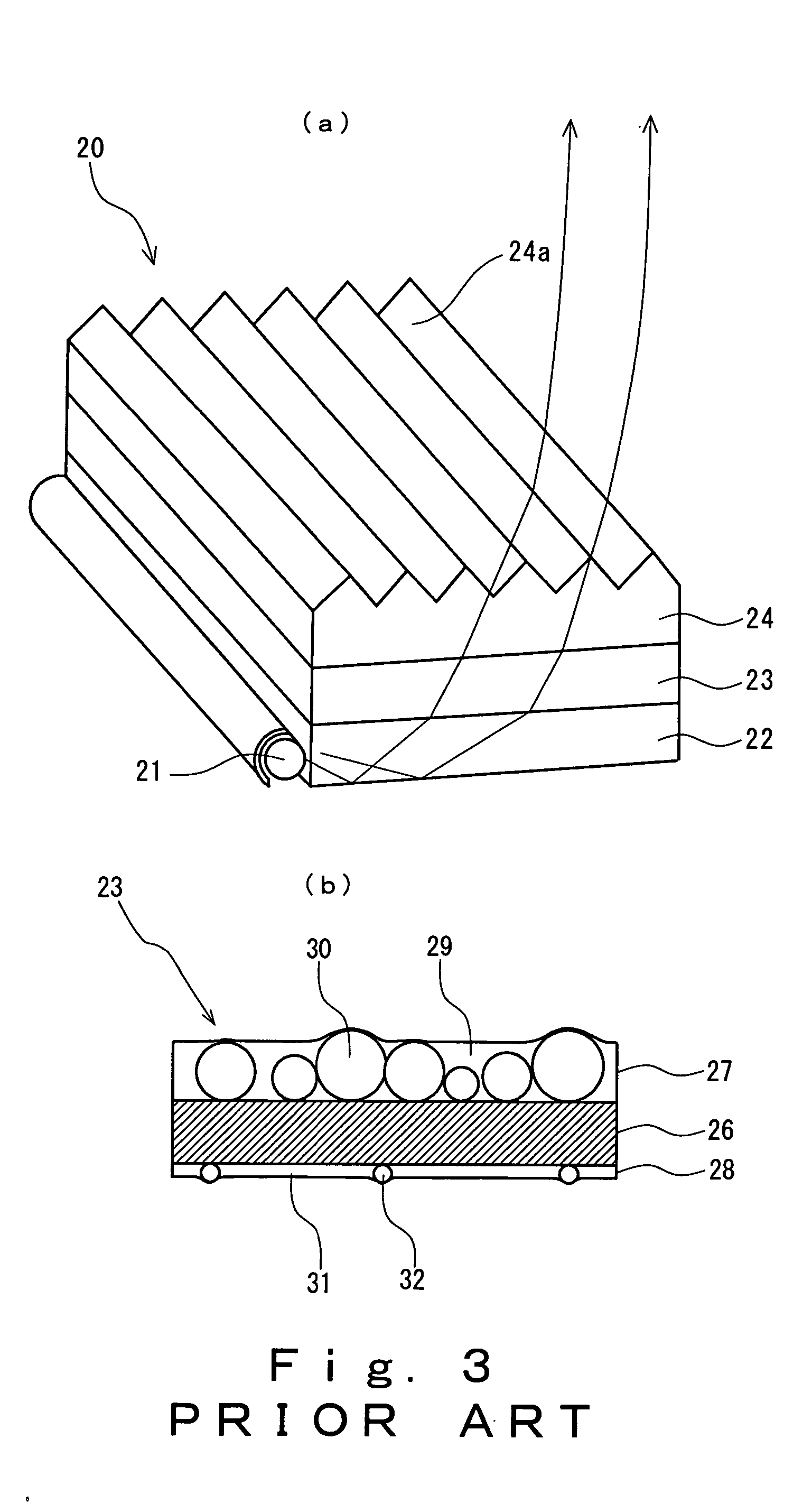

Optical sheet and backlight unit using the same

InactiveUS20050068628A1Increase resistanceImprove stabilityDiffusing elementsElectrographic process apparatusMethacrylateMeth-

An object of the present invention is to provide optical sheets having excellent heat resistance, moisture resistance, thermal dimensional stability and weather resistance, which hardly give rise to bending, yellowing and the like even though they receive generated heat from a lamp and ultraviolet ray irradiation, and to provide backlight units in which reduction of the occurrence of lack in uniformity of the brightness and lowering of the brightness is achieved using the optical sheet. The optical sheet of the present invention has a transparent substrate layer, and an optical layer overlaid to the front face side of the substrate layer. This optical layer includes a light diffusing agent in the binder. This binder is formed from a polymer composition containing (A) a copolymer and (B) a fine inorganic filler. This copolymer (A) includes at least one of a recurring unit derived from a (meth)acrylic ester having a cycloalkyl group, a recurring unit derived from an iso-butyl (meth)acrylate or a recurring unit derived from a tert-butyl (meth)acrylate.

Owner:KEIWA INCORPORATED

Binding agents for polyurethane-based paints

InactiveUS6130308ASynthetic resin layered productsPretreated surfacesTERT-BUTYL METHACRYLATEN-Butyl methacrylate

PCT No. PCT / EP97 / 00149 Sec. 371 Date Aug. 20, 1998 Sec. 102(e) Date Aug. 20, 1998 PCT Filed Jan. 15, 1997 PCT Pub. No. WO97 / 29142 PCT Pub. Date Aug. 14, 1997The invention relates to coating compositions for the production of coatings which are resistant to condensed water and comprise binders based on a polyurethane resin PUR which comprises alpha, omega-polymethacrylatediols (A) as structural units. The alpha, omega-polymethacrylatediols (A) preferably consist of the monomer units methyl methacrylate, ethyl methacrylate, propyl methacrylate, n-butyl methacrylate, isobutyl methacrylate, tert-butyl methacrylate, n-pentyl methacrylate, amyl methacrylate, n-hexyl methacrylate, n-octyl methacrylate, 2-ethylhexyl methacrylate, n-decyl methacrylate, cyclopentyl methacrylate, cyclohexyl methacrylate, 4-tert-butylcyclohexyl methacrylate, cyclooctyl methacrylate, phenyl methacrylate or isobornyl methacrylate or mixtures thereof. The present invention additionally relates to processes for the preparation of such coating compositions and to their preferred use as fillers, basecoats and / or topcoats, especially in connection with automotive production-line finishing and / or refinishing.

Owner:BASF COATINGS AG

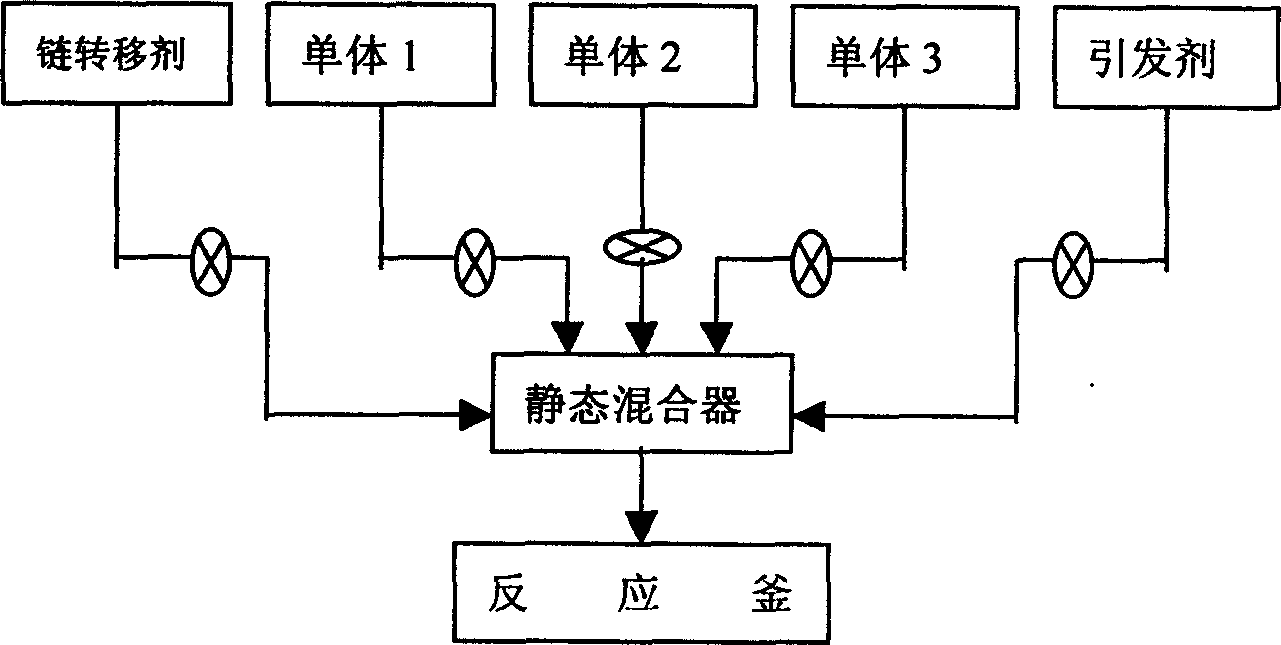

Acroleic acid/polyurethane transparent anode electrophoresis coating and its preparation method

InactiveCN1807528AControl molecular weightIncrease the degree of effective responsePaints for electrolytic applicationsMethacrylateSurface-active agents

The invention relates to an acroleic acid / polyurethane transparent anode electrophoresis coating and its preparation method, comprising the following raw materials (by weight ratio): cationic acrylic polymer 52-85, closed isocyanate cross linking agent 14.5-23.5, non-ionic or / and cationic surface active agent 4.6-8, catalyst 0.6-1.1, chain-transferring agent 0.5-0.8, deionized water 26-51. The cationic acrylic polymer comprises the following raw materials (by weight portions): isobutyl methacrylate 35-55, methyl acrylic ester 23-43, methyl methacrylic hydroxyl propyl ester 15-26, dimethyl amido propyl ester methacrylamide 13.5-23, 2-ethylhexyl methacrylate 13-28, azo-diisobutyronitrile 0.5-1.2, and dimethyl carbinol 35-89.

Owner:冯国贤

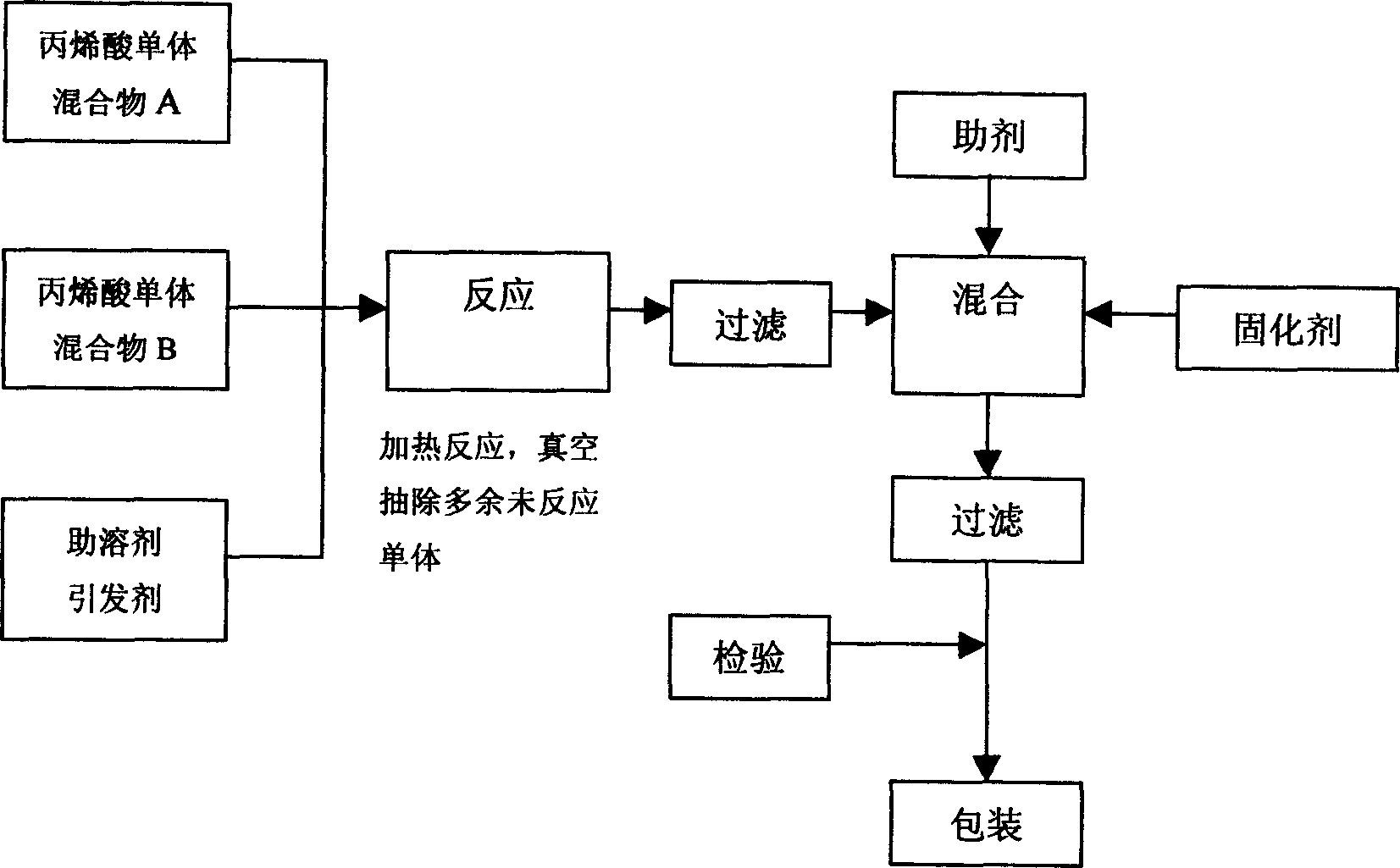

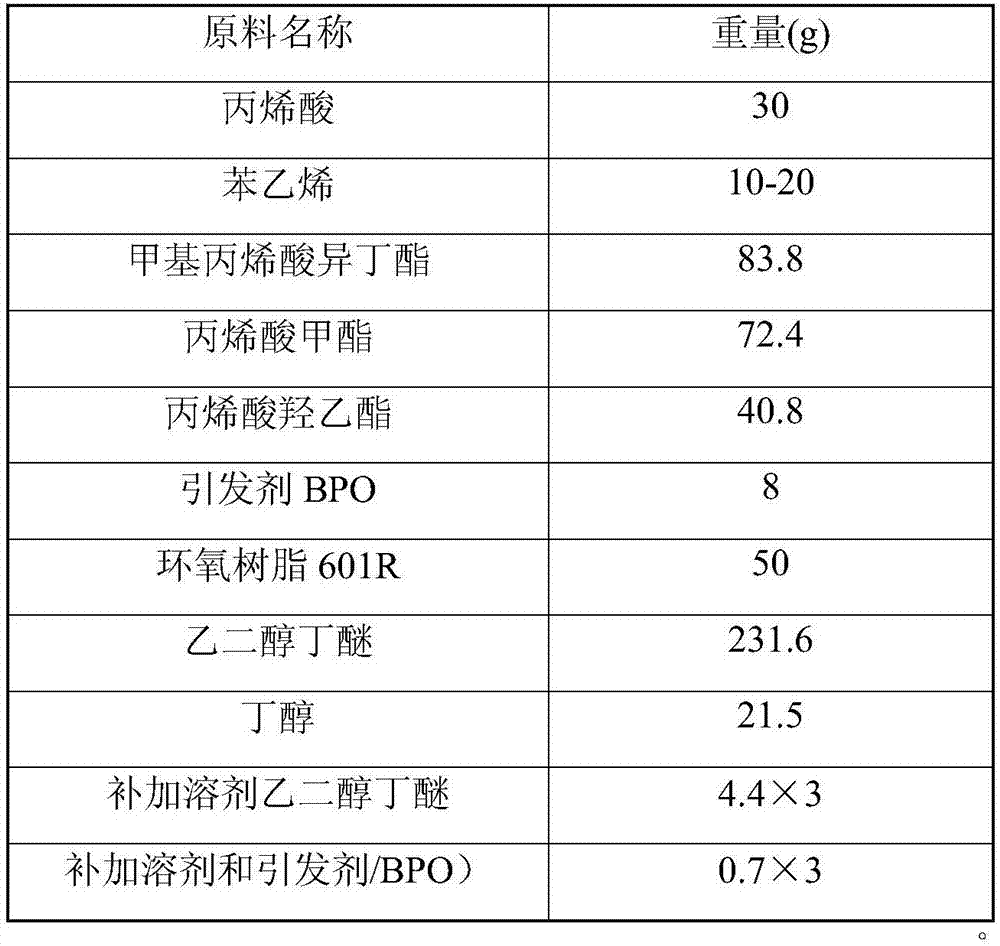

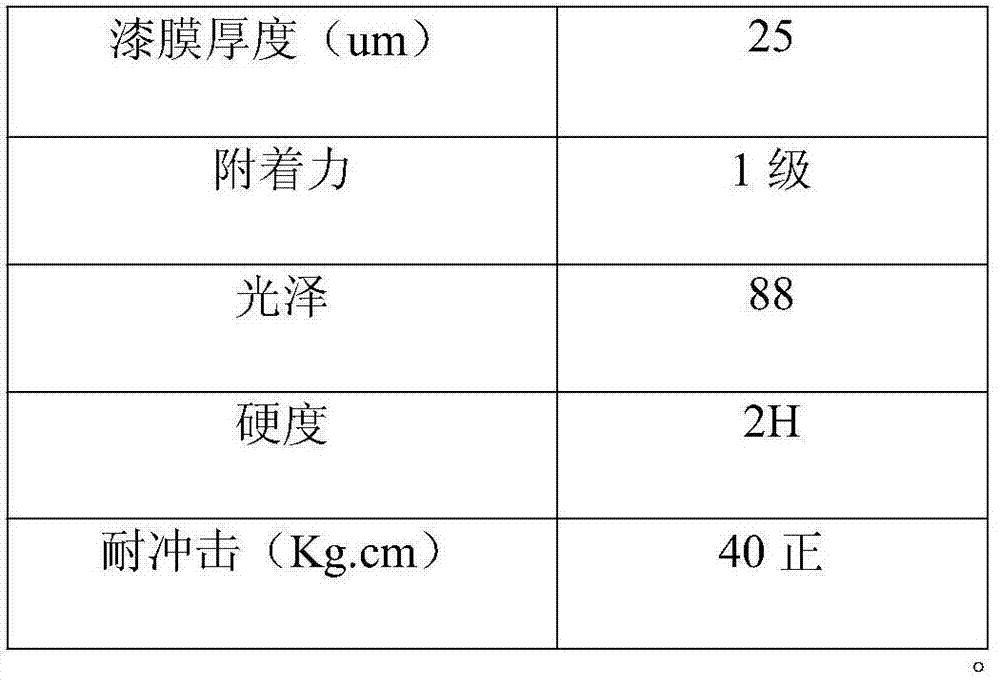

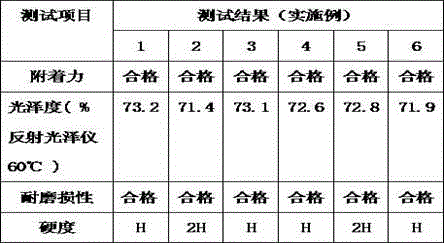

Preparation method of epoxy resin modified waterborne acrylic resin

InactiveCN107236418AImprove adhesionImprove shortcomings such as low glossEpoxy resin coatingsMethacrylateEpoxy

The invention discloses a preparation method of epoxy resin modified waterborne acrylic resin. The epoxy resin modified waterborne acrylic resin is obtained by making a mixed monomer prepared from acrylic acid, styrene, isobutyl methacrylate, methyl acrylate and hydroxyl acrylic acid react with epoxy resin under the action of an initiator. According to the preparation method, a synthetic process is selected through abundant experiments; the VOC (Volatile Organic Compound) in paint can be greatly reduced by prepared and obtained epoxy resin modified waterborne acrylic resin paint; the environment-friendly performance is high. The prepared and obtained epoxy resin modified waterborne acrylic resin paint has excellent adhesive force and is good in glossiness, and further has excellent hardness and impact-resistant performance; the quite good technical effect is gained.

Owner:江苏三木化工股份有限公司 +1

Preparation method of fruit and vegetable preservative film

InactiveCN106832549AImprove antibacterial propertiesImprove preservation qualityFlexible coversWrappersMethacrylateFood hygiene

The invention discloses a preparation method of a fruit and vegetable preservative film. The preparation method comprises the following steps: preparation of a functional filler, preparation of a chitosan colloidal solution, preparation of chitosan / functional filler co-grafted isobutyl methacrylate, preparation of the fruit and vegetable preservative film and the like. The active carbon, travertine and six-ring stone added in the preservative film are all a porous structure. By adding the active carbon, travertine and six-ring stone into the preservative film, micropores are formed in the film, the film is endowed with good air permeability and adsorptivity, and gas and heat generated in the film can be discharged out of those micropores. Under synergistic effects of those substances, the fruit and vegetable preservative film has the following beneficial effects: fresh-keeping quality of fruit and vegetable can be remarkably enhanced, and shelf life of fruit and vegetable is prolonged. In addition, the raw materials used in the invention are all natural components, are nontoxic and harmless, and meet food hygiene requirements.

Owner:安徽民祯活性包装材料有限公司

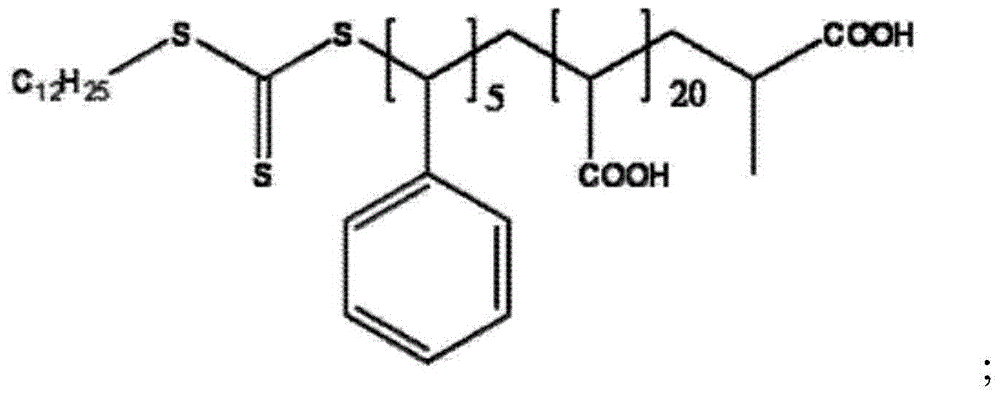

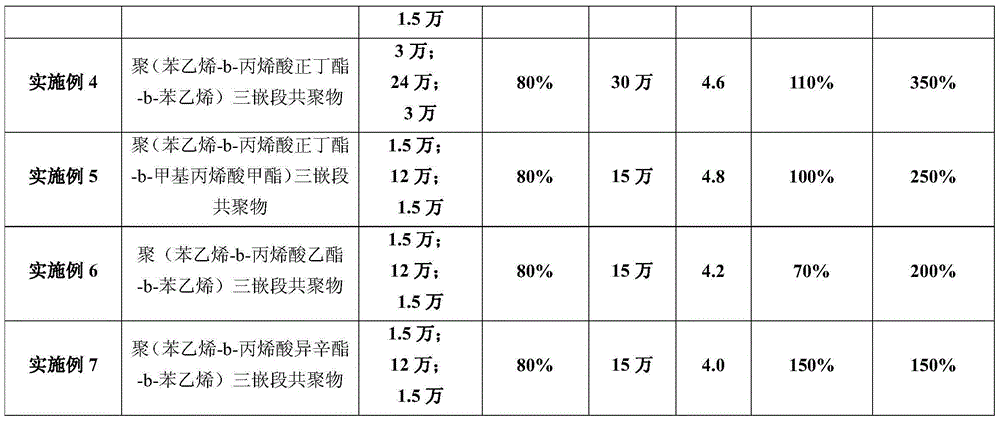

Application of block polymer as dielectric elastomer

ActiveCN105153624AExcellent electrostrictive performanceQuick responseIsooctyl acrylatePolymer science

The invention discloses an application of a block polymer as a dielectric elastomer. The structural general formula of the block polymer is B-C-D, wherein B and D are independently selected from a styrene homopolymer or a methyl methacrylate homopolymer; C is selected from a butyl acrylate homopolymer, a n-butyl acrylate homopolymer, a n-butyl methacrylate homopolymer, a isobutyl methacrylate homopolymer, a tert-butyl acrylate homopolymer, a 2-ethylhexyl acrylate homopolymer, an iso-octyl acrylate homopolymer, an ethyl acrylate homopolymer or a homopolymer of at least two kinds of butyl acrylate, n-butyl acrylate, n-butyl methacrylate, isobutyl methacrylate, tert-butyl acrylate, 2-ethylhexyl acrylate, iso-octyl acrylate and ethyl acrylate. The block polymer can have larger deformation under high-frequency driving without swelling by a solvent and can be used as the dielectric elastomer.

Owner:ZHEJIANG UNIV

Nanometer far infrared ceramic fiber woven fabric and production method of nanometer far infrared ceramic fiber woven fabric

ActiveCN104593931AImprove heat insulation and flame retardant effectImprove wear resistanceConjugated cellulose/protein artificial filamentsWoven fabricsMethacrylateEpoxy

The invention discloses nanometer far infrared ceramic fiber woven fabric. The nanometer far infrared ceramic fiber woven fabric is formed by warp yarns and weft yarns in a woven mode through an air jet loom, and is characterized in that raw materials of the warp yarns and raw materials of the weft yarns comprise, by weight, 27 parts to 33 parts of syndiotactic polypropylene, 10 parts to 14 parts of linear low-density polyethylene, 8 parts to 10 parts of polyurethane films, 16 parts to 22 parts of epoxy resin, 0.4 part to 0.7 part of zinc nitrate, 0.6 part to 0.9 part of magnesium hydrate, 1 part to 3 parts of water glass, 20 parts to 25 parts of nylon yarns, 23 parts to 26 parts of colored cotton fibers, 18 parts to 23 parts of nanometer far infrared ceramic fibers, 21 parts to 24 parts of cellulose acetate fibers, 7 parts to 10 parts of isobutyl methacrylate, 5 parts to 9 parts of peach gum, 1 part to 3 parts of radix bupleuri, 2 parts to 5 parts of fossil fragments, 80 parts to 90 parts of 1-butyl-3-methylimidazolium acetate, 90 parts to 100 parts of 1-allyl-3-methylimidazolium chlorine salt, a proper amount of water and 4 parts to 8 parts of assistants. By means of the nanometer far infrared ceramic fiber woven fabric, the spinnability of plant fibers and the spinning quality are improved, the warmth keeping performance, the wearing resistance, the pilling resistance and the washing resistance of the woven fabric are further improved, and the market prospects are good.

Owner:JIXI YUANDAO AGRI IND TECH

Method for preparing nano calcium carbonate for anti corrosive paints

InactiveCN103555032AHas anti-corrosion effectGood lipophilic and hydrophobicAnti-corrosive paintsMethacrylateSlurry

The invention discloses a method for preparing nano calcium carbonate for anti corrosive paints, wherein the method comprises the following steps of: (1) adding a proper amount of water in light calcium carbonate, grinding the mixture into nano slurry, adding 1-2 parts of silane coupling agent KH580 under 40-50 DEC C, stirring for 30-50 min, then adding 0.3-0.5 parts of anti-oxidant 1076, and 1-2 parts of anti-oxidant BHT, stirring for 10-20min, filtrating, drying and grinding; (2) uniformly mixing 0.1-0.2 parts of ammonium molybdate, 1-2 parts of isobutyl methacrylate, 5-7 parts of rosin resin, and 10-15 parts of solvent, to obtain a modified liquid for standby application; and (3) adding the powder prepared in the step (1) into a high speed mixer, maintaining temperature at 70-80 DEG C, adding the modified liquid, drying after stirring for 20-30min, and grinding to form a nano powder.

Owner:ANHUI SHENGJIA COLOR PRINTING PACKING

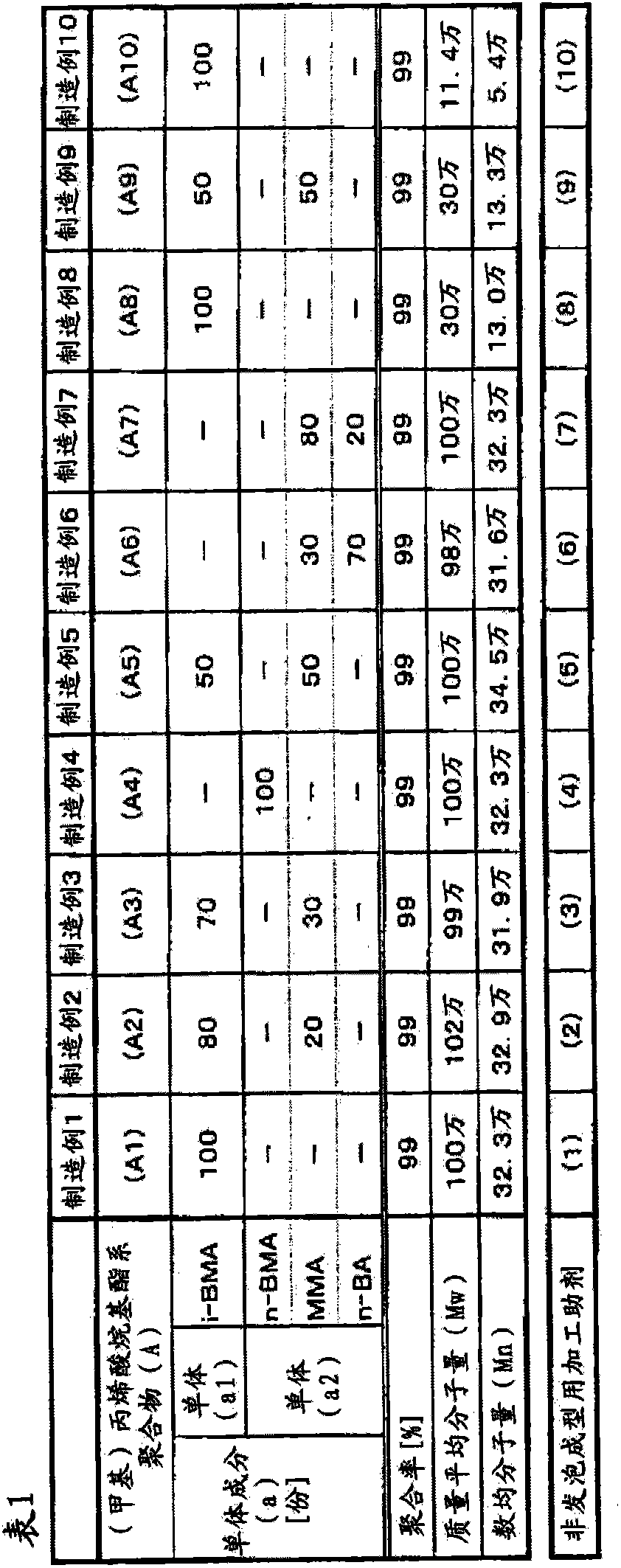

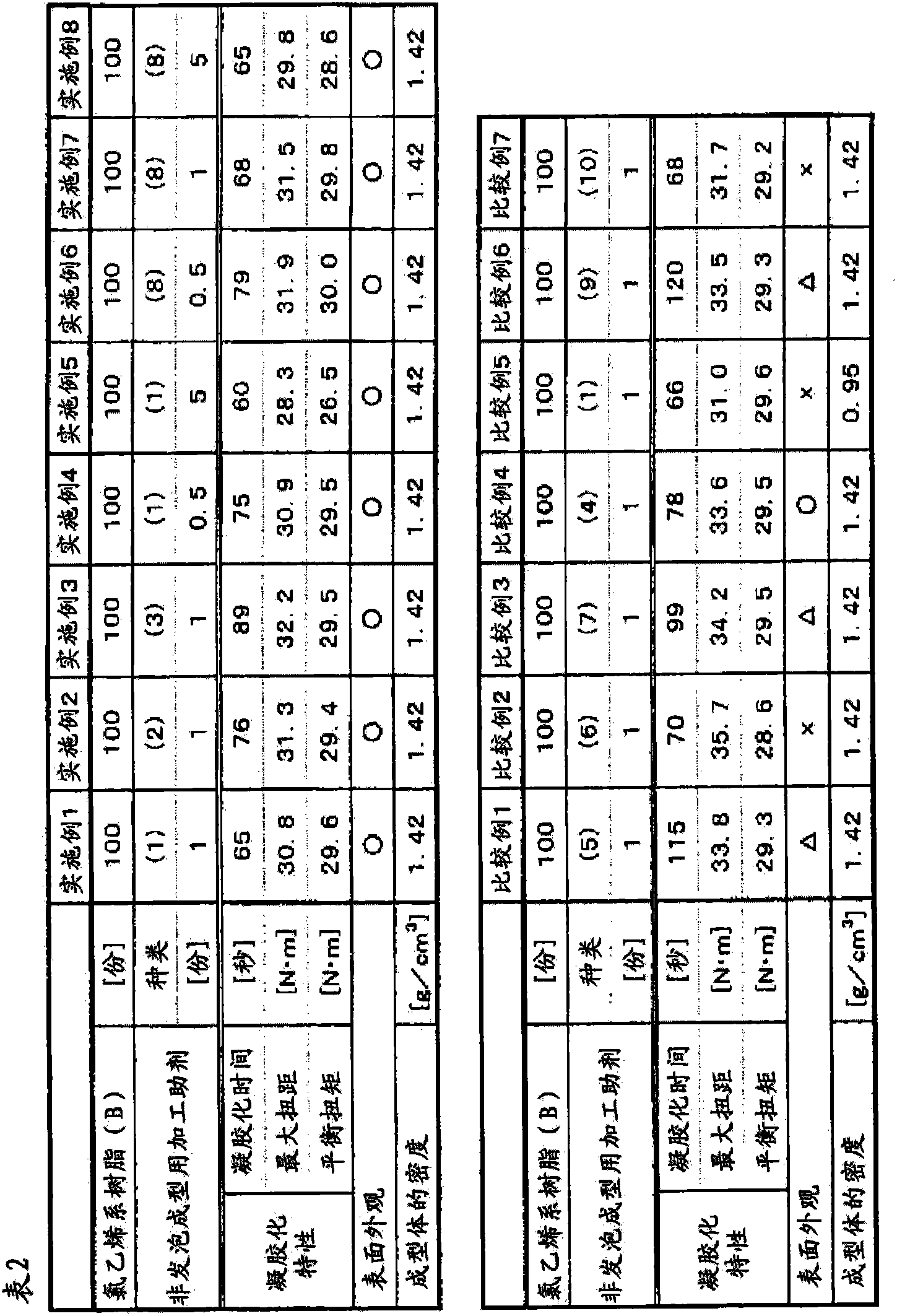

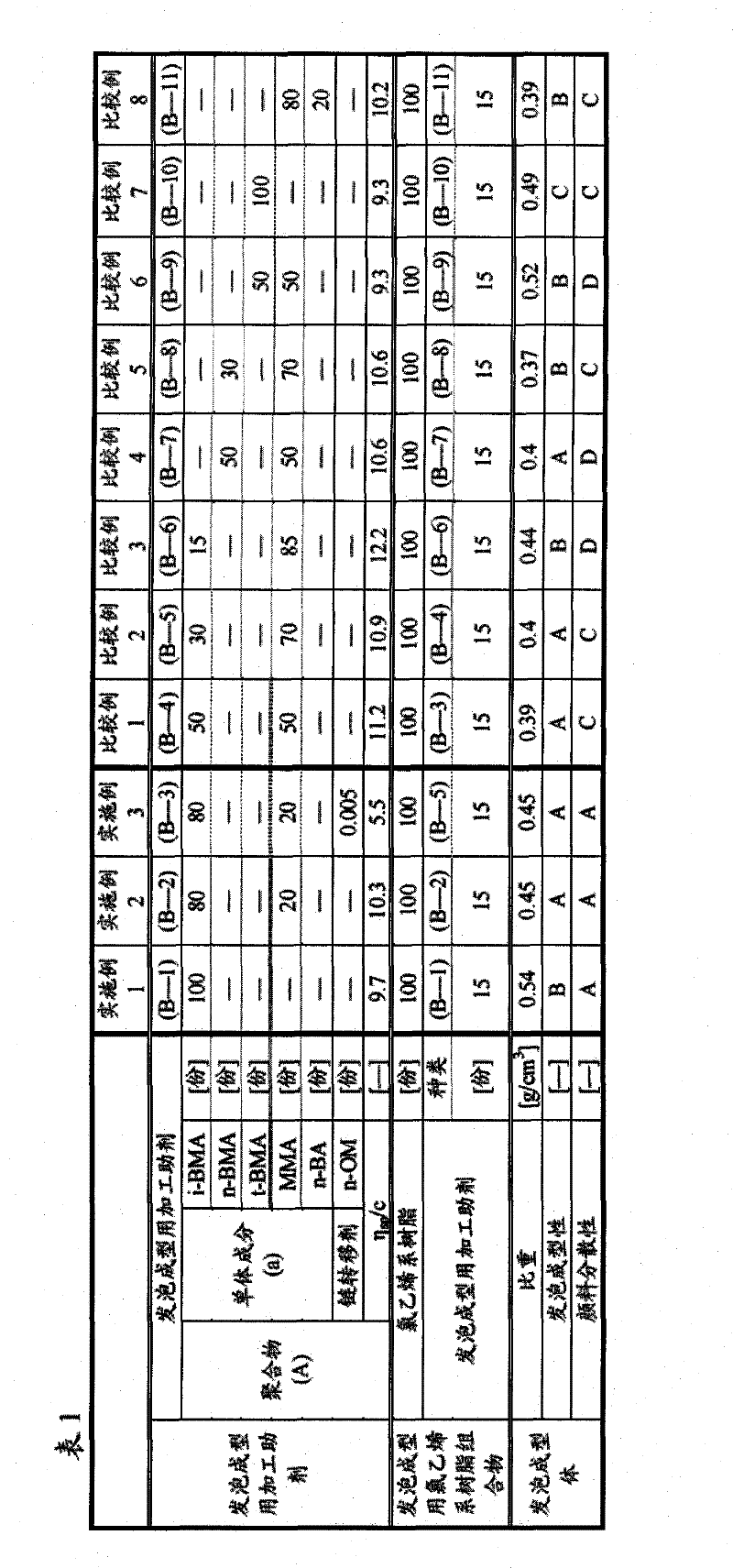

Non-foaming treatment auxiliary agent, resin composition, and molded article

Provided is a treatment auxiliary agent for improving the gelling properties and moldability of a vinyl chloride resin composition and obtaining a molded article having good surface appearance. A non-foaming treatment auxiliary agent comprises an alkyl (meth)acrylate polymer (A) containing 65 mass% or greater of i-butyl methacrylate (a1) units and having a mass-average molecular weight of 200,000 to 2,000,000.

Owner:MITSUBISHI CHEM CORP

Composition and system for hair coloring and color retention

ActiveUS20070245502A1Good colorReducing dripping and bleedingCosmetic preparationsHair cosmeticsColored hairHair dyes

A composition and system for use in coloring hair and improving color retention properties in colored hair. The composition of the present invention preferably includes hair dye and a copolymer of isobutylmethacrylate and silicone grafted acrylate in isoparaffin, whereby these components are combined in an aqueous based, or alternatively, a nonaqueous based solution. The system includes the step of applying the hair coloring solution to the hair.

Owner:FAROUK SYST

Cable lettering ink

The invention belongs to the field of printing technology, and particularly relates to cable lettering ink which is characterized by comprising the following raw materials in parts by weight: 4-6 parts of polyvinyl chloride resin, 5-9 parts of acrylate polymer, 30-40 parts of methyl ethyl ketone, 13-18 parts of toluene, 5-10 parts of isobutyl methacrylate, 10-18 parts of tetrahydrofuran, 3-5 parts of benzidine yellow or titanium dioxide or lithopone with fineness of 400-800 meshes, 6-10 parts of 2-lead ethylcaproate, 0.3-0.5 part of methylparaben or propylparaben or butylparaben and 3-4.5 parts of butyl acetate. The invention also discloses a preparation method of the lettering ink. The cable lettering ink and the preparation method provided by the invention have the main beneficial effects that the preparation method is simple and easy to master, and the qualified rate of the finished product is high; the lettering ink has the advantages of high adhesion, high drying speed, bright luster and longer shelf life.

Owner:STATE GRID CORP OF CHINA +1

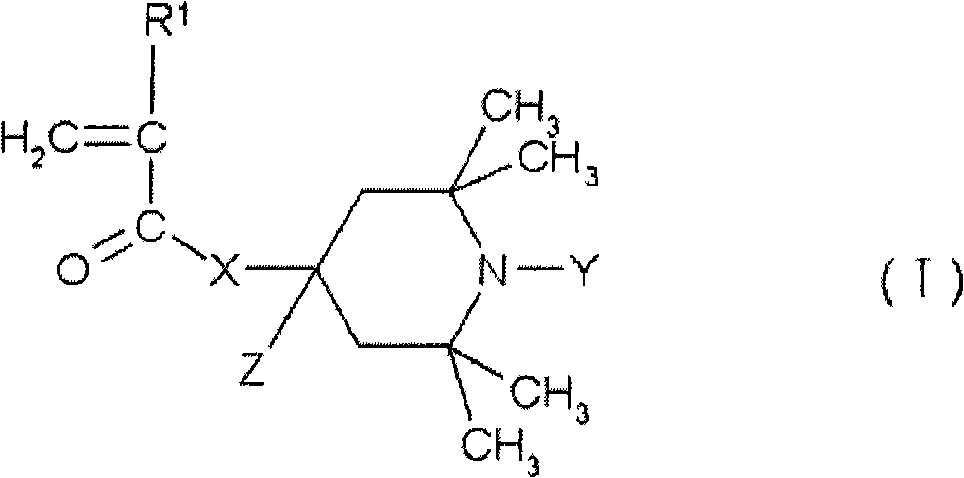

Stabilizer for polyolefin resin and stabilized polyolefin resin composition

Disclosed is a stabilizer capable of providing a polypropylene resin (PP resin) with high thermal stability. Also disclosed is a PP resin composition having high stability into which the stabilizer is added. Specifically disclosed is a stabilizer containing a copolymer (A) which is obtained by polymerizing an unsaturated monomer mixture composed of 1-50 parts by mass of an ethylenically unsaturated monomer (a) represented by the general formula (I) below and having a piperidyl group in a molecule, 50-99 parts by mass of at least one monomer (b) selected from isobutyl methacrylates, alkyl (meth)acrylates having an alkyl group with 6-13 carbon atoms and aromatic vinyl monomers, and 0-20 parts by mass of an ethylenically unsaturated monomer (c) other than the components (a) and (b) (with the total of the components (a), (b) and (c) being 100 parts by mass). (I) In the formula, R represents a hydrogen atom or an alkyl group having 1-2 carbon atoms; X represents an oxygen atom or an imino group; Y represents a hydrogen atom or an alkyl group or alkoxyl group having 1-20 carbon atoms; and Z represents a hydrogen atom or a cyano group.

Owner:MITSUBISHI CHEM CORP

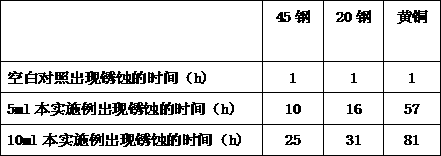

Anhydrous protectant chemical composition

InactiveUS20080114109A1Spread fastIncreased durabilityPlastic/resin/waxes insulatorsOrganic dyesMethacrylateMaterials science

A highly resilient clear surface protectant is provided comprising of a copolymer, such as an isobutyl methacrylate, methyl methacrylate, or acrylic copolymer, in a hexamethyldisiloxane system. The hexamethyldisiloxane combined with a cosolvent package in a composition with a copolymer resin, such as an acrylic copolymer, enhances physical properties of coatings, such as unusual migration and spread and wetting on surfaces. The protectant formulation exhibits greater substantivity to surfaces such as aluminum, steel, brass, stainless steel and copper, and possesses enhanced spreading ability on surfaces to which it is applied resulting in improvement in physical properties in protection of metal surfaces against the deterioration caused by oxidation, degradation and corrosion.

Owner:MEGUIARS

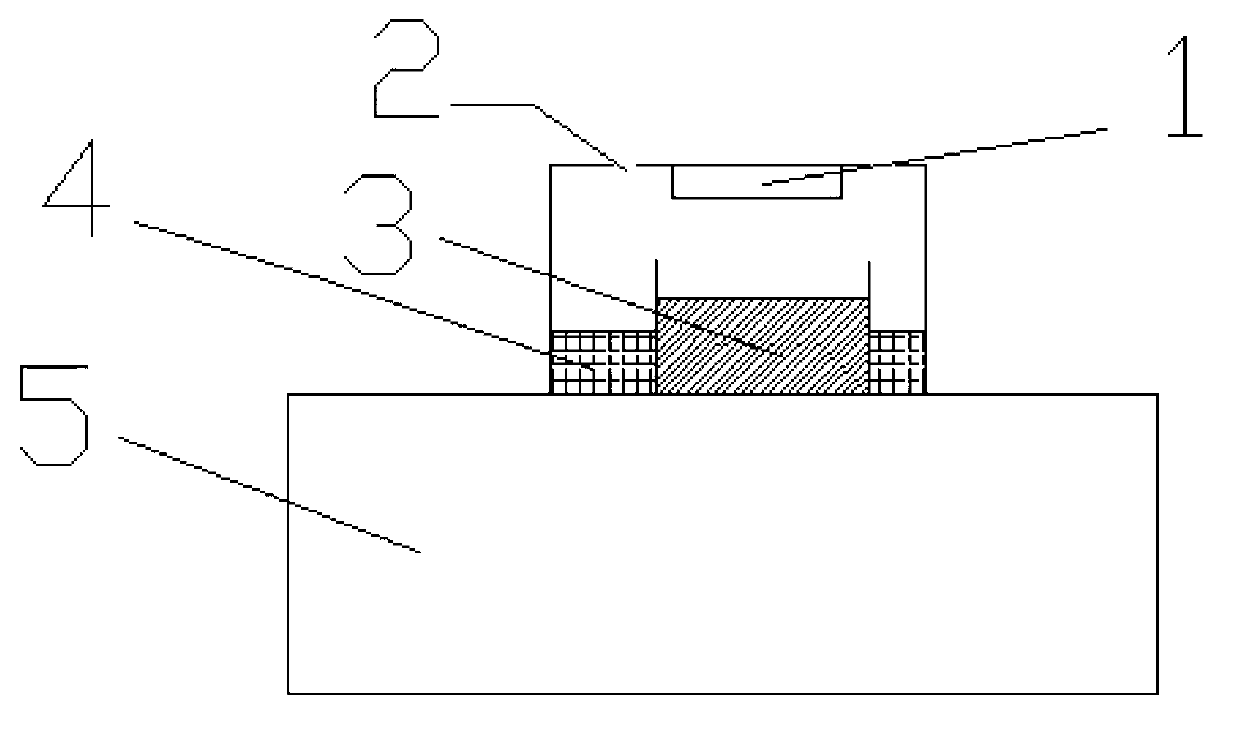

Metal rust-preventive oil comprising hydroxyethyl methacrylate

InactiveCN103215598AGood gas phase anti-rust effectGood vapor phase antirust effectPolymer scienceComposite film

The invention discloses metal rust-preventive oil comprising hydroxyethyl methacrylate. The oil is prepared from the raw materials of: No.120 solvent oil, hydroxyethyl methacrylate, a silane coupling agent KH 602, paraffin, acetyl triethyl citrate, an antioxidant 1076, coconut oil fatty acid diethanolamide, lanolin magnesium soap, benzotriazole, 2-aminoethyl heptadecenyl imidazoline, magnesium naphthenate, tetraethoxysilane, sorbitan monooleate, ethanol, isobutyl methacrylate, modified nano-scale shale powder, an antioxidant 1010, a composite film-forming material, and polyethylene glycol. The rust-preventive oil provided by the invention has excellent contact rust resistance and good gas-phase rust resistance. The rust-preventive oil provided by the invention provides good gas-phase rust resistance and contact rust resistance for steel and brass.

Owner:ANHUI FANCHANG COUNTY WANNAN VALVE CASTING

Alcohol-resistant hydroxyl acrylic resin refinishing paint used for automobile

InactiveCN103773163AGood gloss and color retentionStrong water and chemical resistanceAnti-corrosive paintsCyclohexanonePolymer science

The invention discloses an alcohol-resistant hydroxyl acrylic resin refinishing paint used for an automobile. Raw materials of the alcohol-resistant hydroxyl acrylic resin refinishing paint comprise, by weight, 100 parts of an alcohol-resistant hydroxyl acrylic resin, 3-5 parts of a dispersant, 1 part of nano titanium dioxide, 0-0.5 part of cyclohexanone, 2-2.5 parts of an epoxy curing agent and 20-25 parts of a solvent 1, wherein the alcohol-resistant hydroxyl acrylic resin comprises, by weight, 100 parts of methyl methacrylate, 8-20 parts of perfluoroalkylethyl acrylate monomers, 15 parts of hydroxyethyl acrylate, 25-35 parts of butyl acrylate, 3-7 parts of isobutyl methacrylate, 1.5-5 parts of an initiator and 50-70 parts of a solvent 2. The alcohol-resistant hydroxyl acrylic resin refinishing paint has good light protection and color protection properties, strong water-resistant and chemical-resistant properties, strong alcohol-resistant property and high corrosion-resistant capacity, can be dried rapidly, and is convenient for operation. The solvents are low in cost; and a preparation process is simple.

Owner:NANJING HENGAN RESIN CHEM

Anti-yellowing carpentry paint

InactiveCN103773161AImprove corrosion resistanceGuaranteed aestheticsAnti-corrosive paintsPolymer scienceAcrylic resin

The invention discloses an anti-yellowing carpentry paint which comprises the following raw materials by weight: 100 parts of alcohol resistant hydroxyl acrylic resin, 30-35 parts of titanium dioxide, 15-18 parts of polyethylene, 1-3 parts of an active agent, 0.8 part of activated carbon, 0-0.5 part of a leveling agent and 1-3.5 parts of a film-forming agent; wherein the alcohol resistant hydroxyl acrylic resin comprises the following components by weight: 100 parts of methyl methacrylate, 8-20 parts of perfluoroalkylethyl acrylate monomer, 15 parts of hydroxyethyl acrylate, 25-35 parts of butyl acrylate, 3-7 parts of iso butyl methacrylate, 1.5-5 parts of an initiator and 50-70 parts of a solvent 2. The alcohol resistant hydroxyl acrylic resin has a high alcohol resistant performance and high corrosion resistance, is low in solvent price and simple in preparation process, can be widely used in auto repair paints, and can improve the sunproof and anti-corrosion performance of the auto repair paints. The anti-yellowing carpentry paint is strong in corrosion resistance, is anti-yellowing, can keep carpentry beautiful for a long time, and is easy to use, simple in preparation and low in cost.

Owner:NANJING HENGAN RESIN CHEM

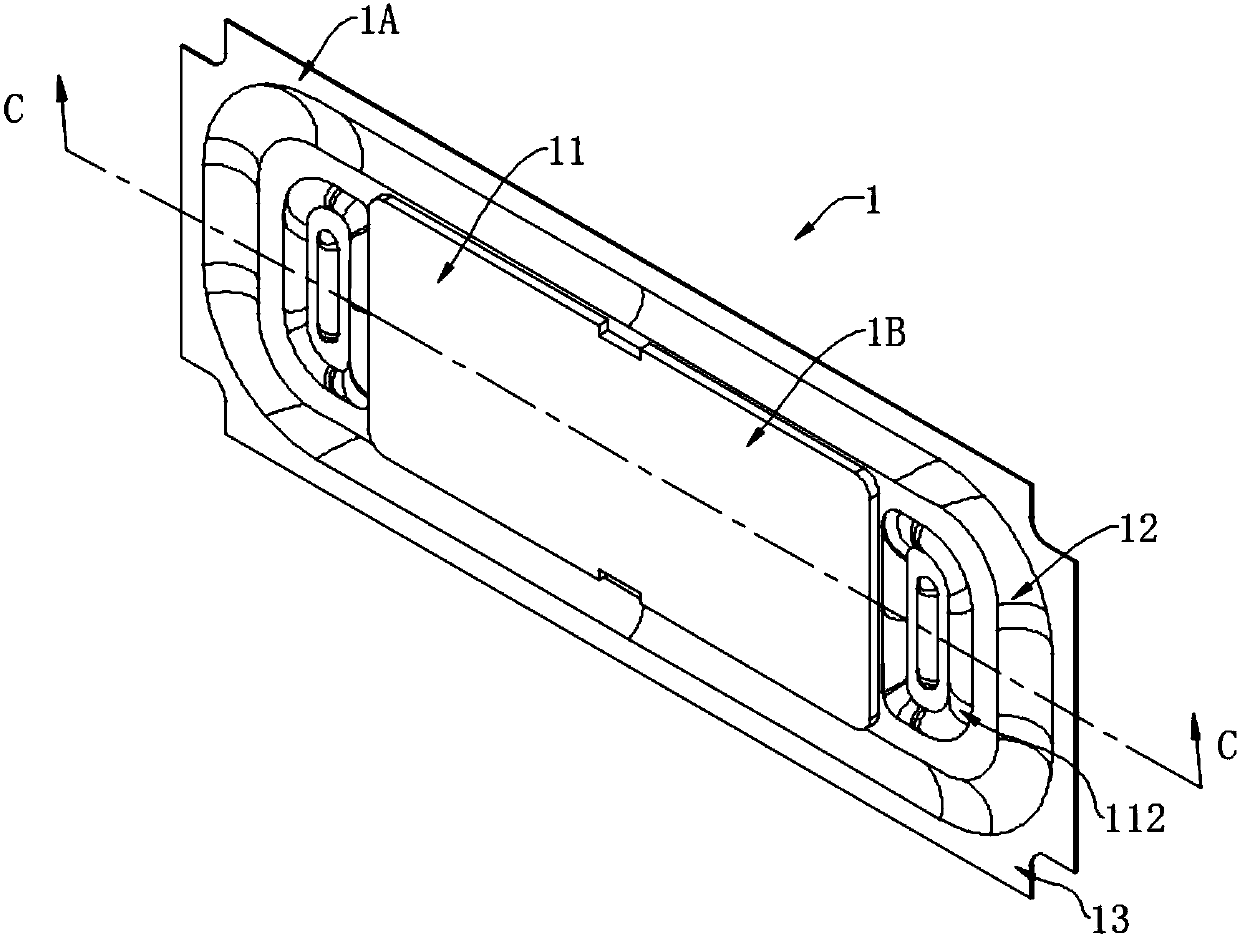

Double-sided adhesive for ultra-wideband loudspeaker diaphragm and preparation method thereof

ActiveCN107892889AImprove support strengthImprove support rigidityNon-macromolecular adhesive additivesMacromolecular adhesive additivesMethacrylateUltra-wideband

The invention provides a double-sided adhesive for an ultra-wideband loudspeaker diaphragm and a preparation method thereof, and relats to the technical field of viscose materials. The raw materials of the double-sided adhesive include monomers, tackifying resin, an organic solvent, an initiator, and a cross-linking agent. In parts by weight, the monomers include 50 to 60 parts of isooctyl acrylate, 10 to 15 parts of butyl acrylate, 2 to 5 parts of isobutyl methacrylate and 2 to 6 parts of acrylic acid. The weight part number of the tackifying resin is 22 to 28 parts, the weight part number ofthe organic solvent is 80 to 90 parts, the weight part number of the initiator is 0.1 to 0.5 part, and the weight part number of the cross-linking agent is 0.05 to 0.4 part. In addition, the presentinvention also relates to the preparation method of the double-sided adhesive. By selecting the suitable copolymerization monomer, functional monomer and tackifying resin, a polymerization reaction isperformed under the action of the initiator and the cross-linking agent for obtaining the double-sided adhesive. The double-sided adhesive has high strength, strong adhesive properties, high temperature resistance, and ductility resistance, etc. Especially when applied to diaphragms of loudspeakers, the double-sided adhesive can guarantee the ultra-wideband effect of loudspeakers and meet the demand of high-definition voice.

Owner:XIAMEN GREAT SOUND TECH

Silk-screen printing ink based on PVC (polyvinyl chloride) substrate

The invention discloses silk-screen printing ink based on a PVC (polyvinyl chloride) substrate. The silk-screen printing ink comprises components in parts by weight as follows: 20-30 parts of PVC resin, 1-6 parts of polypropylene glycol, 2-8 parts of polyester resin, 5-10 parts of isobutyl methacrylate, 3-7 parts of tetrahydrofuran, 2-7 parts of an antifoaming agent, 3-9 parts of a leveling agent, 5-12 parts of a coupling agent, 5-15 parts of nanofiller and 30-40 parts of a solvent. The prepared silk-screen printing ink has good leveling property when printed on a PVC material and is suitable for fine silk-screen printing; meanwhile, with adding of the coupling agent and the nanofiller, the silk-screen printing ink has better adhesiveness and better abrasive resistance and glossiness and is applicable to the field of silk-screen printing of electronic and electrical products and the like containing a PVC casing.

Owner:陈良伢

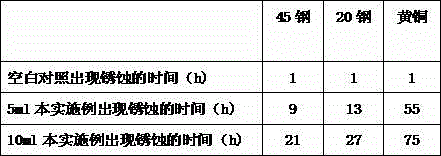

Metal rust-preventative oil containing methacrylic acid isobutyl ester

InactiveCN103147081AGood gas phase anti-rust effectGood vapor phase antirust effectPolymer scienceSuccinimide

The invention discloses metal rust-preventative oil containing methacrylic acid isobutyl ester. The metal rust-preventative oil containing the methacrylic acid isobutyl ester is characterized by comprising the following raw materials, by weight, 110 parts-120 parts of number 120 solvent oil, 1 part-2 parts of lanolin, 1 part-2 parts of the methacrylic acid isobutyl ester, 1.5 parts-2.8 parts of a silane coupling agent KH 570, 0.5 part-0.7 part of epoxidized soybean oil, 0.3 part-0.4 part of span 80, 0.5 part-0.7 part of antioxidant 1135, 0.3 part-0.5 part of octyl phenol polyoxyethylene ether, 0.1 part-0.2 part of naphthenic acid magnesium, 0.2 part-0.5 part of benzotriazole, 1.5 parts-1.7 parts of 2-aminoethyl-heptadecenyl-imidazoline, 0.5 part-1part of hydrogenation tallow amine, 2.1 parts-3.4 parts of polyisobutene acid glyceride, 0.4 part-0.5 part of polyisobutyl-succinimide, 0.3 part-0.8 part of alkyl glycoside, 6 parts-8 parts of composite film-forming materials, 0.3 part-0.5 part of modified nanometer vermiculite powder, and 10 parts-12 parts of propylene glycol. The metal rust-preventative oil containing the methacrylic acid isobutyl ester has good contact rust-preventative performance and a good gaseous phase rust-preventative effect. The metal rust-preventative oil containing the methacrylic acid isobutyl ester has a good gaseous phase rust-preventative effect and a contact rust-preventative effect to steel and brass.

Owner:ANHUI FANCHANG COUNTY WANNAN VALVE CASTING

Processing assistant for expansion molding, vinyl chloride resin composition for expansion molding, and expansion molded body

Disclosed is a vinyl chloride resin expansion molded body having fine and uniform foam cells and excellent appearance. Also disclosed are a processing assistant for expansion molding, which is useful for production of the vinyl chloride resin expansion molded body, and a vinyl chloride resin composition for expansion molding. The processing assistant for expansion molding comprises a polymer (A) which is obtained by polymerizing a monomer component (a) containing not less than 65% by mass of isobutyl methacrylate, and the polymer (A) has a reduced viscosity (?sp / c) of not less than 4, when measured at 25 DEG C by dissolving 0.1 g of the polymer (A) into 100 ml of chloroform.

Owner:MITSUBISHI CHEM CORP

Anhydrous protectant chemical composition

InactiveUS7625966B2Spread fastIncreased durabilityPlastic/resin/waxes insulatorsOrganic dyesMethacrylatePhysical property

A highly resilient clear surface protectant is provided comprising of a copolymer, such as an isobutyl methacrylate, methyl methacrylate, or acrylic copolymer, in a hexamethyldisiloxane system. The hexamethyldisiloxane combined with a cosolvent package in a composition with a copolymer resin, such as an acrylic copolymer, enhances physical properties of coatings, such as unusual migration and spread and wetting on surfaces. The protectant formulation exhibits greater substantivity to surfaces such as aluminum, steel, brass, stainless steel and copper, and possesses enhanced spreading ability on surfaces to which it is applied resulting in improvement in physical properties in protection of metal surfaces against the deterioration caused by oxidation, degradation and corrosion.

Owner:MEGUIARS

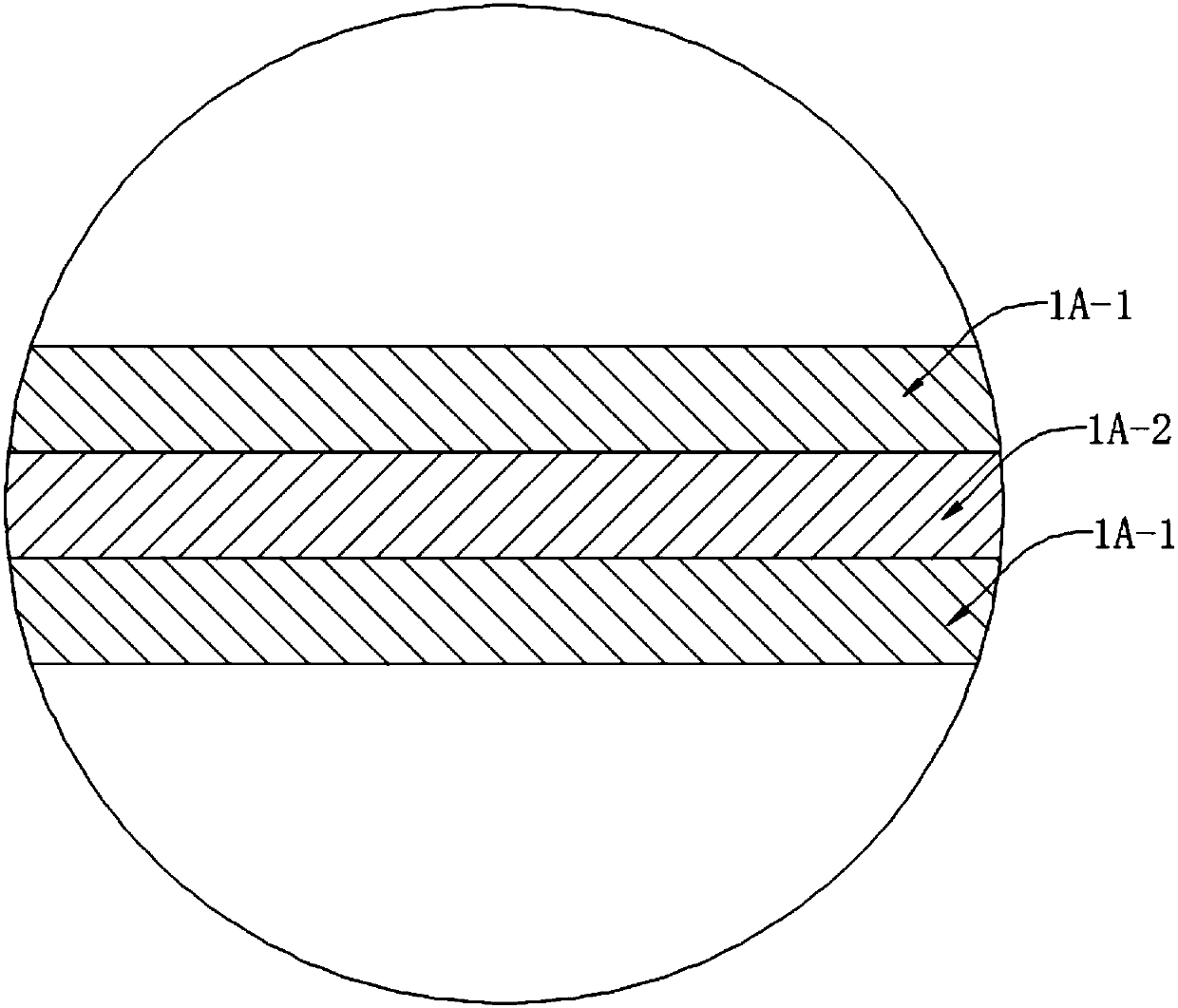

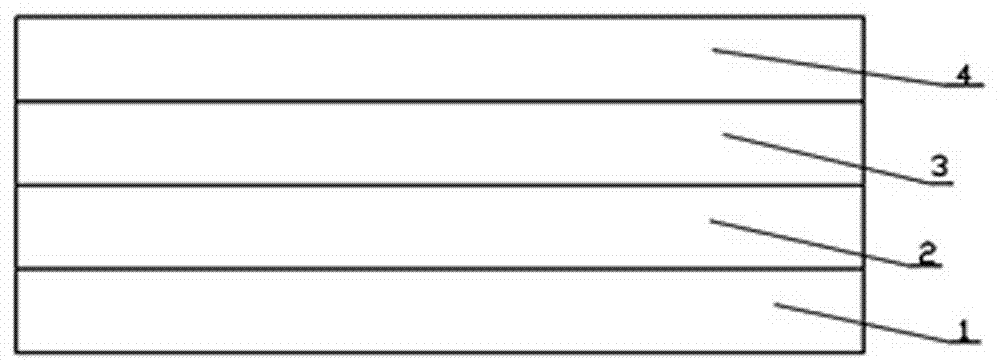

Composite lamella

ActiveCN103173155AIncreasing the thicknessDoes not affect the use ofFilm/foil adhesivesOrganic non-macromolecular adhesivePolyesterMethacrylate

The invention relates to a composite lamella which comprises a viscose layer pasted with a pasted object, a composite film layer arranged on the upper end surface of the viscose layer and used for blocking permeation, an anti-static layer arranged on the upper end surface of the composite film and used for preventing electrostatic interference, and an anti-scrape layer arranged on the upper end surface of the anti-static layer and used for preventing scrape, wherein the colloid of the viscose layer comprises the following components in parts by weight: 5-20 parts of acrylamide, 10-30 parts of ethyl methacrylate, 5-25 parts of isobutyl methacrylate, 10-25 parts of polyurethane and the balance of water; the colloid weight of the viscose layer is greater than 1g; the composite film layer is a polyester film; and the thickness of the composite lamella can be set as 0.15-0.25mm, and preferably 0.25mm. According to the invention, the viscosity with the pasted object is increased, and the thickness of the composite lamella is increased without influencing the using effect.

Owner:SUZHOU BRIDGE ELECTRONICS

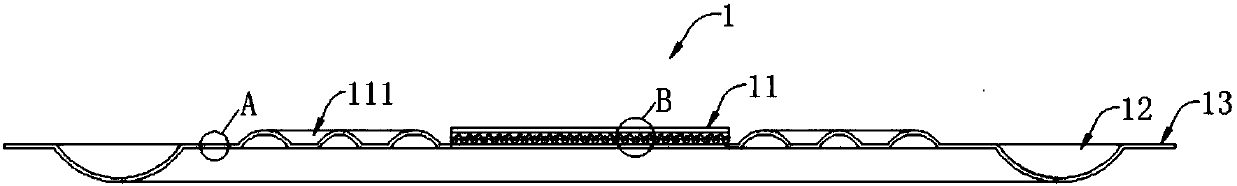

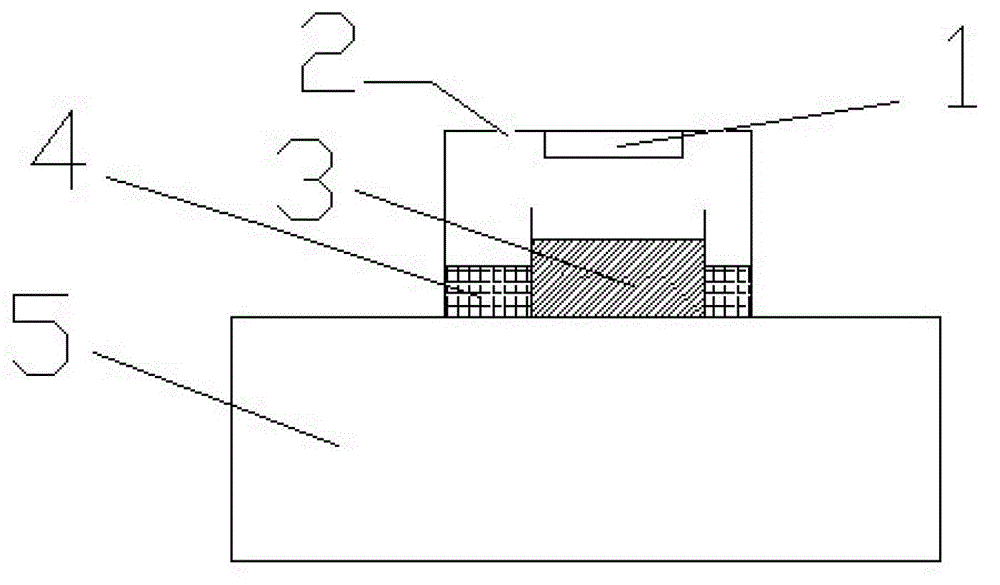

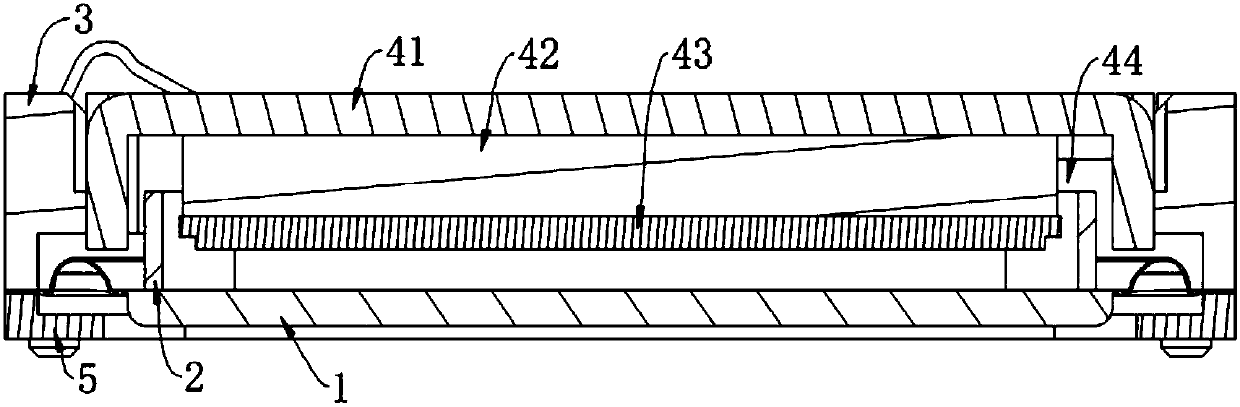

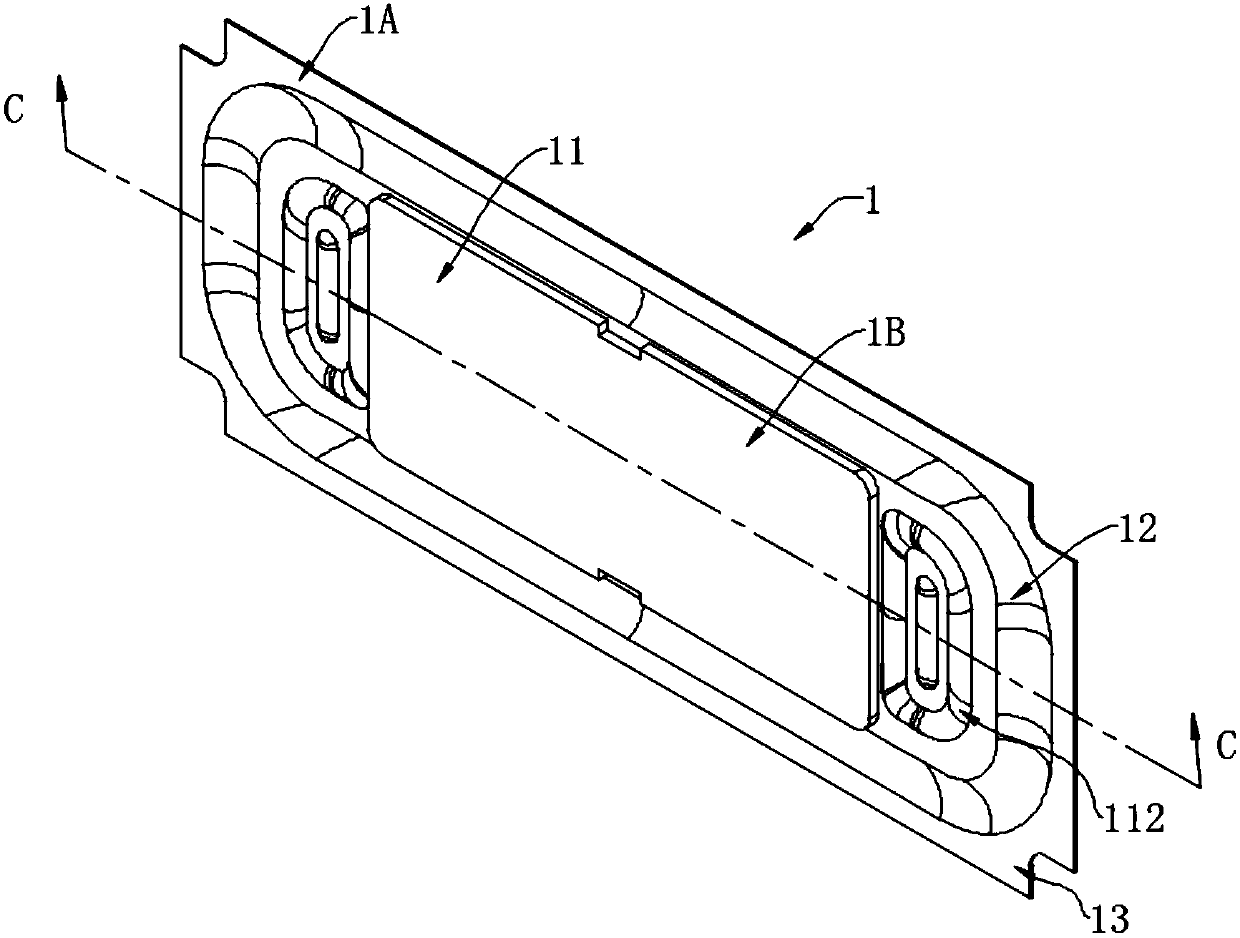

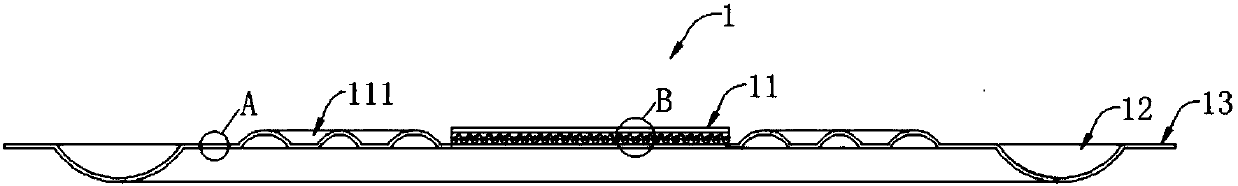

Vibrating diaphragm for ultra-wideband loudspeaker and loudspeaker using vibrating diaphragm

ActiveCN107948890AImprove rigidityBroaden the high frequency bandwidthElectrical transducersLoudspeakersMethacrylateIsooctyl acrylate

The invention provides a vibrating diaphragm for an ultra-wideband loudspeaker. The vibrating diaphragm comprises a base layer made of a composite material; the vibrating diaphragm is divided into a spherical top, a folding ring and a suspension edge from the middle to the edge; a middle sticker is attached at the spherical top; the composite material comprises a glue layer and first constraint layers arranged on the two sides of the glue layer; and the glue layer is made of double-sided glue; the double-sided glue comprises, by weight, a monomer, 22-28 parts of tackifying resin, 80-90 parts of organic solvent, 0.1-0.5 part of initiator and 0.05-0.4 part of cross-linking agent, wherein the monomer comprises, by weight, 50-60 parts of iso-octyl acrylate, 10-15 parts of butyl acrylate, 2-5 parts of isobutyl methacrylate and 2-6 parts of acrylic acid. According to the vibrating diaphragm for the ultra-wideband loudspeaker, the base layer made of the composite material is adopted, and thefirst constraint layers with good rigidity are combined with the improvement of the formula of the double-sided glue, so that the whole vibrating diaphragm has relatively good rigidity, and the high frequency bandwidth of the vibrating diaphragm is effectively expanded.

Owner:XIAMEN GREAT SOUND TECH

Amphiphilic block copolymer and preparation method thereof

ActiveCN104725582ANo organic solvent residueComplete shapePharmaceutical non-active ingredientsEmulsion delivery(Hydroxyethyl)methacrylateGlycidyl methacrylate

The invention discloses an amphiphilic block copolymer, which is copolymerized by a hydrophilic alpha-methyl unsaturated olefinic bond monomer polymer chain segment and a vinyl acetate monomer polymer chain segment of hydrophilic supercritical carbon dioxide, so as to obtain the amphiphilic block copolymer with the number-average molecular weight of 3,000-50,000, wherein the alpha-methyl unsaturated olefinic bond monomer polymer chain segment accounts for 20%-80% of weight of the amphiphilic block copolymer; and the alpha-methyl unsaturated olefinic bond monomer is any one of a methyl methacrylate monomer, an ethyl methacrylate monomer, a methacrylic acid normal propyl acetate monomer, a methacrylic isopropyl ester monomer, an n-butyl methacrylate monomer, an isobutyl methacrylate monomer, a tert-butyl methacrylate monomer, a glycidyl methacrylate monomer, a hydroxyethyl methylacrylate monomer or polyethylene glycol dimethacrylate. The invention further discloses a preparation method of the amphiphilic block copolymer.

Owner:SOUTHEAST UNIV

Polyvinyl chloride composite plastic and preparation method thereof

ActiveCN103951910AImprove antibacterial propertiesHigh tensile strengthLow-density polyethyleneMethacrylate

The invention belongs to the field of high-molecular materials, and discloses a polyvinyl chloride composite plastic and a preparation method thereof. The polyvinyl chloride composite plastic is prepared from the following components in parts by weight: 35-45 parts of polyvinyl chloride, 3-4 parts of sodium dihydrogen phosphate, 8-14 parts of tetramethyl siloxane, 5-12 parts of zinc oxide, 22-25 parts of low-density polyethylene, 6-13 parts of polyethylene wax, 3-4 parts of magnesium stearate and 13-17 parts of isobutyl methacrylate. The preparation method of the polyvinyl chloride composite plastic comprises the following steps of: fast mixing in a high-speed mixer; stirring; extruding through a double screw extruder; granulating, and the like. The polyvinyl chloride composite plastic prepared through the method disclosed by the invention has the advantages of better antibacterial property and higher tensile strength and can be used for the preparation of related products as an antibacterial plastic.

Owner:JIEYANG JIAYI PLASTIC PROD CO LTD

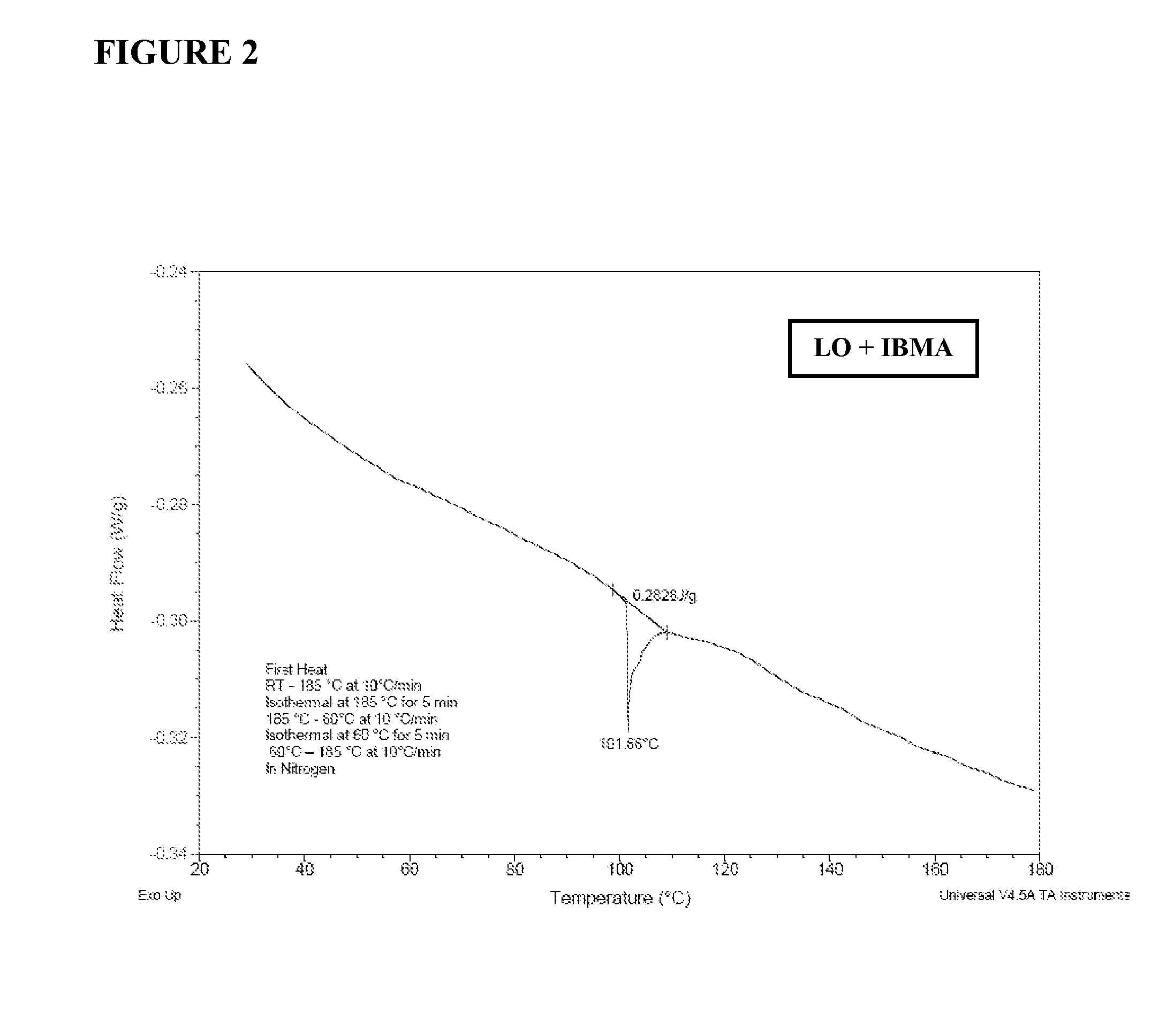

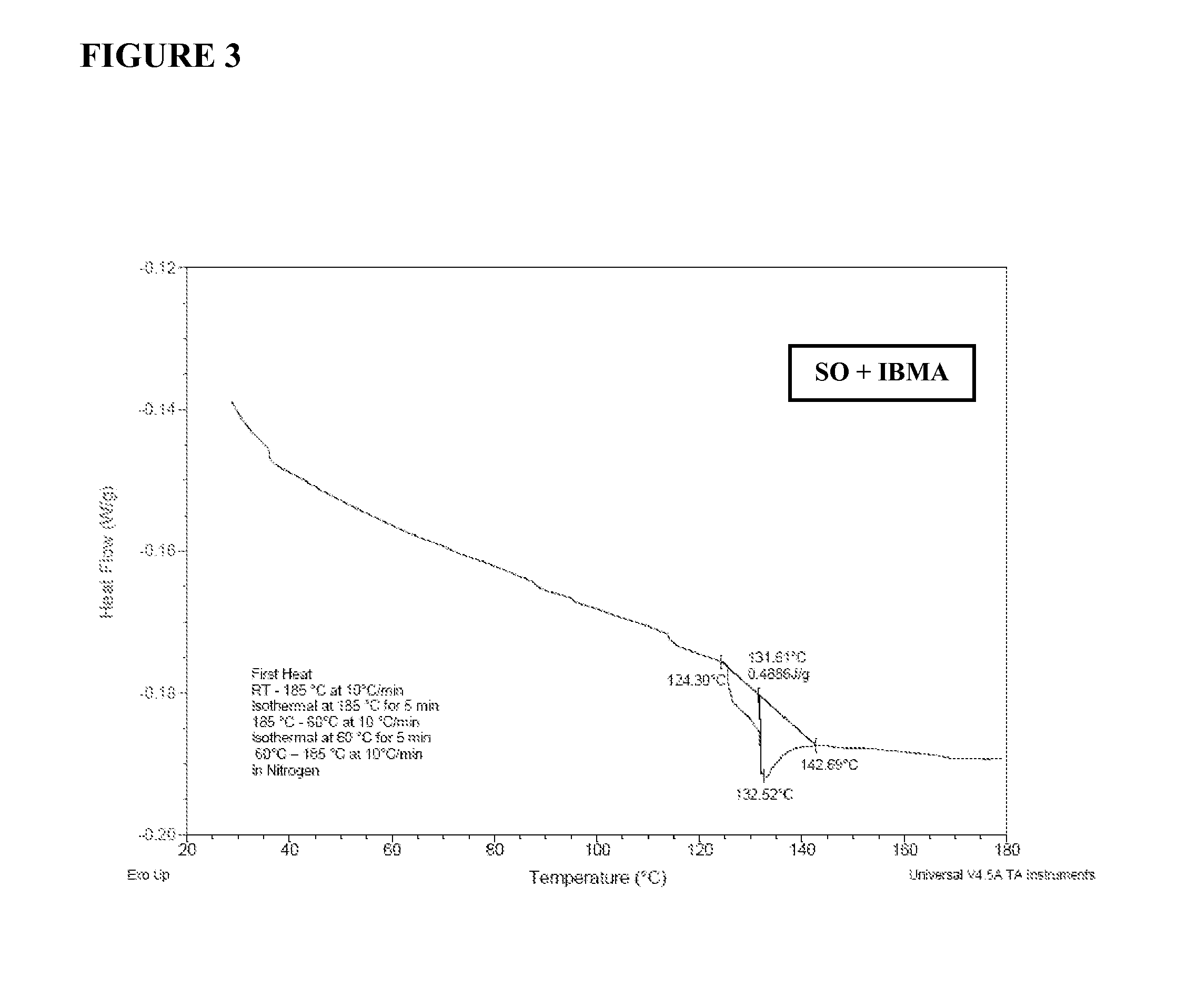

Process for producing compositions for use in removal of dispersed, solubilized, and/or emulsified undesired species from water and gases

ActiveUS20120316251A1High affinityEnhanced characteristic and effectivenessBiocideOther chemical processesMethacrylateFresh water

Disclosed is a method of making coagulant and viscoelastic compositions for use in removal of dispersed, solubilized, and emulsified oils and hydrocarbons and other noxious species from water and air. The composition comprises thermal reaction products of blends of fatty acids derived, isolated and purified from drying and semi-drying oils such as linseed, safflower, and tung oil with a polymer such as for example poly(isobutyl methacrylate) and can include a solvent. The product of the invention facilitates cohesion of oils and hydrocarbons independent of agitation and temperature and may be used in both salt and fresh water, air and other gaseous streams.

Owner:MYCELX TECH CORP

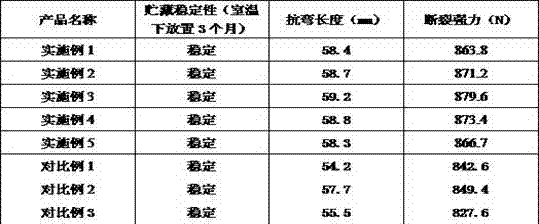

Stiffening agent and preparation method thereof

The invention provides a stiffening agent and a preparation method thereof. The preparation method includes the following steps that 1, stearyl methacrylate, isobutyl methacrylate, n-propyl methacrylate, maleic anhydride, lauryl acrylate, silico triol alginate, glycerol monolaurate, modified soybean phospholipid, vanillin, keratin and deionized water are mixed and stirred to obtain a mixture A; 2,potassium persulfate, silver nitrate and deionized water are mixed and stirred to obtain a mixture B; 3, half of the mixture A and half of the mixture B are mixed and kept warm; 4, the remaining mixture A and the remaining mixture B are dropwise added to obtain a reaction solution C; 5, the reaction solution C is cooled down and a sodium hydroxide solution is added for stirring; 6, polyvinylpyrrolidone, polyethylene oxide, polyanionic cellulose and polyvinyl alcohol are added for stirring to obtain a mixture; 7, the mixture is cooled to room temperature and discharged to obtain the stiffeningagent. The stiffening agent has stable performance, long bending length, excellent breaking strength and good stiffening effect.

Owner:SUZHOU INST OF TRADE & COMMERCE

Alcohol-soluble acrylic resin

The invention provides an alcohol-soluble acrylic resin. The alcohol-soluble acrylic resin is prepared from hard monomers with the glass transition temperature being higher than 25DEG C and soft and hard monomers with the glass transition temperature being lower than 25DEG C according to a mass ratio of 50:50-90:10 through a free radical copolymerization reaction; the soft monomers are selected from at least one of n-butyl methacrylate, methyl acrylate, ethyl acrylate, n-butyl acrylate, isooctyl acrylate, lauryl methacrylate and ethoxyethyl methacrylate; and the hard monomers are selected from at least one of methyl methacrylate, methyl methacrylate, isobutyl methacrylate, hydroxyethyl methylacrylate, hydroxypropyl methacrylate and styrene. The glass transition temperature of the alcohol-soluble acrylic resin is 25-45DEG C, and the weight average molecular weight of the alcohol-soluble acrylic resin is 30,000-100,000. The alcohol-soluble acrylic resin has moderate adhesion and good toughness, can be dissolved in ethanol and other alcoholic solvents, and can meet use performance requirements of environmentally-friendly inks and environmentally-friendly coatings.

Owner:SHANGHAI WEIQUAN NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com