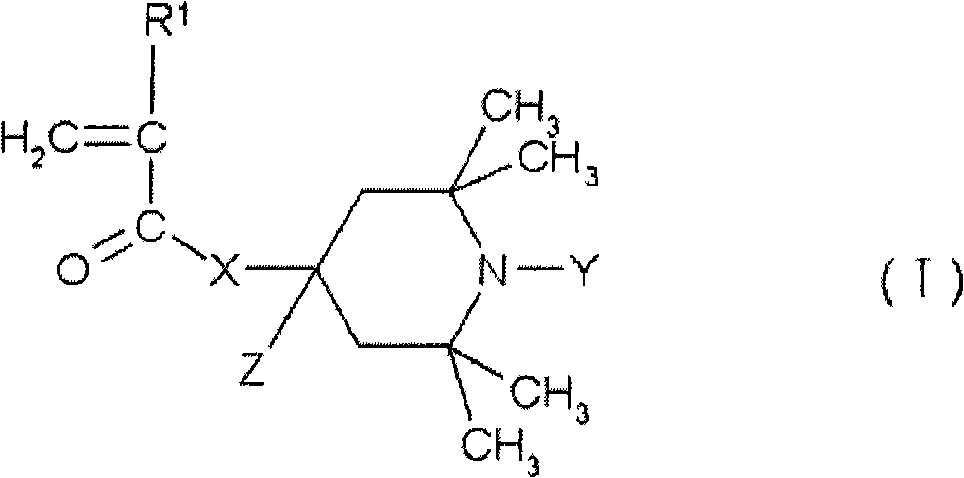

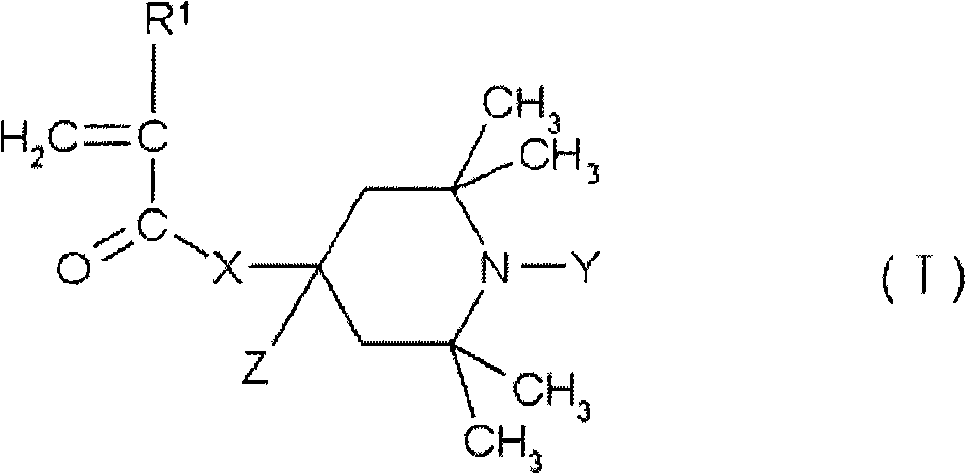

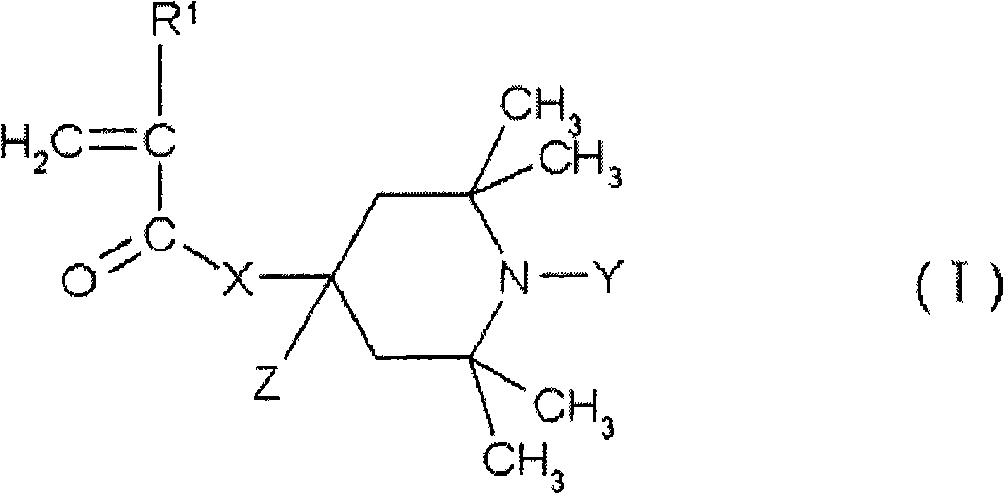

Stabilizer for polyolefin resin and stabilized polyolefin resin composition

A technique for polyolefin resins and stabilizers, which is applied in the field of stabilizers for thermoplastic resins and stabilized resin compositions, and can solve problems such as insufficient stability and inability to obtain sufficient diffusion properties of polypropylene resins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] In a flask equipped with a stirrer, a reflux condenser, a temperature control device, a drip pump, and a nitrogen gas introduction tube, add 45 parts of deionized water, followed by 0.2 parts of 28% ammonia solution and the emulsion formulated in the ratio shown in Table-1 5 parts were put into the reaction container, and while replacing the inside of the reaction container with nitrogen, after heating up to 75°C, an initiator solution in which 0.1 part of ammonium persulfate (polymerization initiator) was dissolved in 5 parts of water was added to form seed particles. Measure the temperature of the solution with a thermometer, confirm the exothermic peak, add the remaining emulsion dropwise at an internal temperature of 75°C for 4 hours, and then perform emulsion polymerization at an internal temperature of 75°C for 2 hours to form an emulsion dispersion. After cooling the obtained emulsion dispersion to room temperature, spray drying was carried out at an inlet tempera...

Embodiment 2~4、 comparative example 1、2

[0080] Carry out the emulsion polymerization of composition shown in Table-1 with the method identical with embodiment 1, reclaim solid with the spray drying method identical with embodiment 1 for the obtained emulsion dispersion. In the same manner as in Example 1, after preparing the resin composition according to the ratio described in Table-1, a test piece was prepared and subjected to an accelerated light resistance test and a heat resistance test. The test results are shown in Table-1.

Embodiment 5

[0082] Put 145 parts by mass of deionized water, 0.5 parts by mass of dispersant A, 0.1 part by mass of sodium sulfate, and 0.1 part by mass of 28% ammonia solution into a reaction vessel equipped with a stirrer and a thermometer, and then add the monomers of the composition shown in Table-1 0.6 parts by mass of mixture and polymerization initiator lauroyl peroxide. While stirring the contents, the temperature was raised from 40°C to 90°C over 1 hour and 25 minutes, and the temperature of the contents was brought to 90°C. After reaching 90° C., stirring was further carried out for 1 hour and 30 minutes, followed by cooling to obtain a suspension of polymer particles. The resulting suspension was filtered through a filter cloth made of nylon with a pore diameter of 45 μm, washed sufficiently with deionized water, and then dried at 50° C. for 24 hours to obtain a copolymer (A). Next, after preparing the resin composition according to the ratio described in Table-1, a test panel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com