Non-foaming treatment auxiliary agent, resin composition, and molded article

A processing aid and non-foaming technology, which is applied in the field of non-foaming molding processing aids, resin compositions, and moldings, can solve the problem of inability to obtain surface-appearing moldings, and the vinyl chloride-based resin composition has not yet fully solidified. Eliminate problems such as gelation, achieve good surface appearance, good gelation properties, and improved gelation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

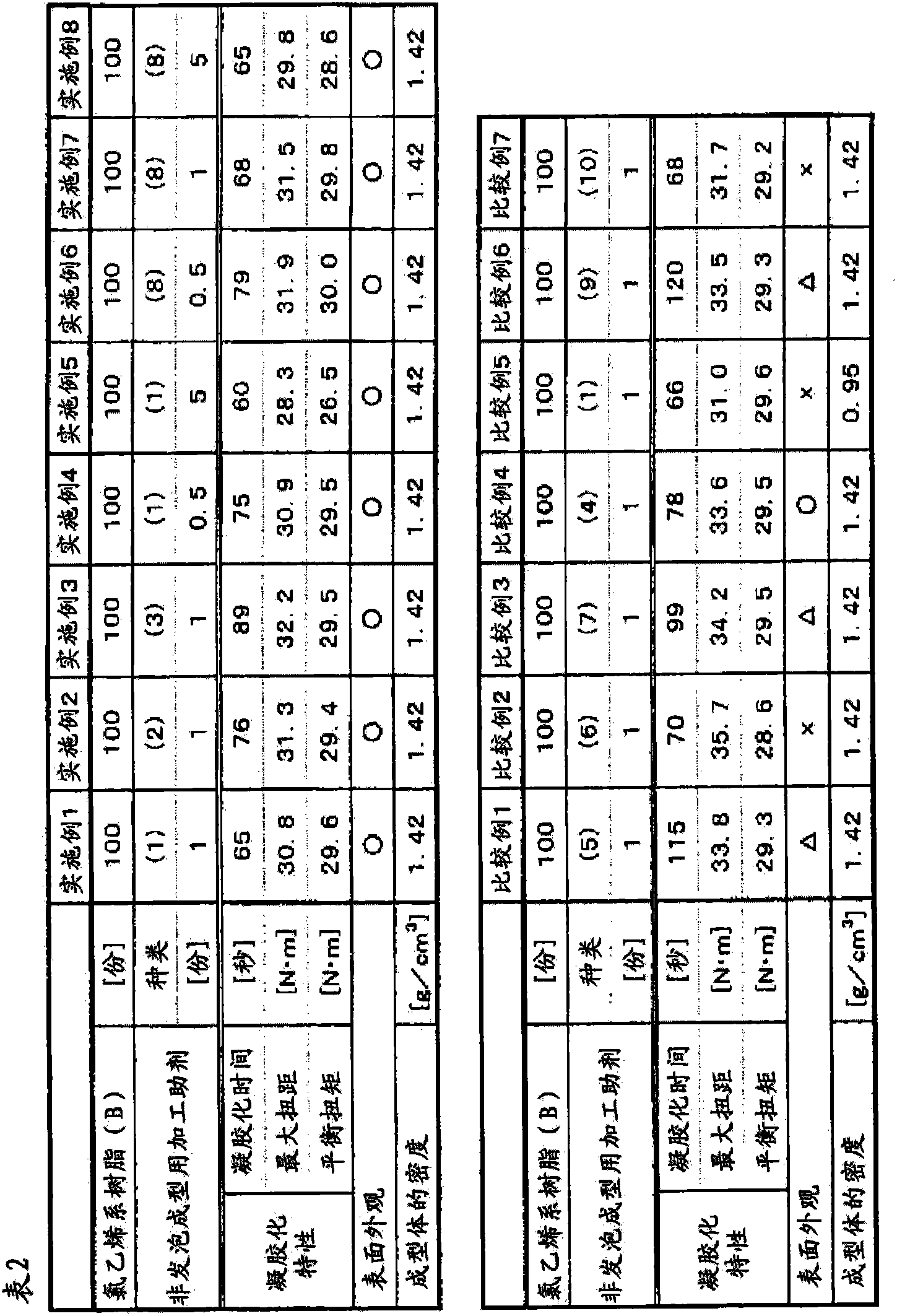

[0078] Hereinafter, although an Example demonstrates this invention concretely, the technical scope of this invention is not limited to the following Example.

[0079] In addition, "part" and "%" in an Example represent "part by mass" and "% by mass", respectively.

[0080] (1) Polymerization rate

[0081] The polymerization rate of the alkyl (meth)acrylate polymer (A) was measured by adding a polymerization inhibitor (hydroquinone) to the emulsion of the polymer collected after polymerization, heating at 180° C. for 30 minutes, and measuring the solid content. And compare it with the calculated value obtained from the feeding amount to calculate.

[0082] (2) Mass average molecular weight (Mw), number average molecular weight (Mn)

[0083] The Mw and Mn of the (meth)alkyl acrylate polymer (A) are based on the tetrahydrofuran (THF) soluble component of the (meth)alkyl acrylate polymer (A) as a sample, and the Gel permeation chromatography (machine type name "HLC-8220", manu...

manufacture example 1

[0095] [Production example 1] Production of alkyl (meth)acrylate polymer (A1)

[0096] 100 parts (1000 g) of isobutyl methacrylate, 0.02 parts of n-octyl mercaptan, 300 parts of deionized water and 1.1 parts of sodium dodecylbenzenesulfonate were stirred for 6 minutes using a homomixer at 10000 rpm to obtain an emulsified mixture .

[0097] The above-mentioned emulsified mixture was put into a detachable flask (capacity of 5 liters) equipped with a thermometer, a nitrogen introduction pipe, a cooling pipe, and a stirring device, and the inside of the container was replaced with nitrogen.

[0098] Next, the inner temperature was raised to 60° C., and 0.15 parts of potassium persulfate was added.

[0099] Then, heating and stirring were continued for 2 hours to complete the polymerization, and an emulsion of an alkyl (meth)acrylate polymer (A1) was obtained. The obtained emulsion of the alkyl (meth)acrylate type polymer (A1) was dripped at 100 parts of hot water containing 5 p...

manufacture example 2~7

[0102] [Production Examples 2 to 7] Production of Alkyl (Meth)acrylate Polymers (A2) to (A7)

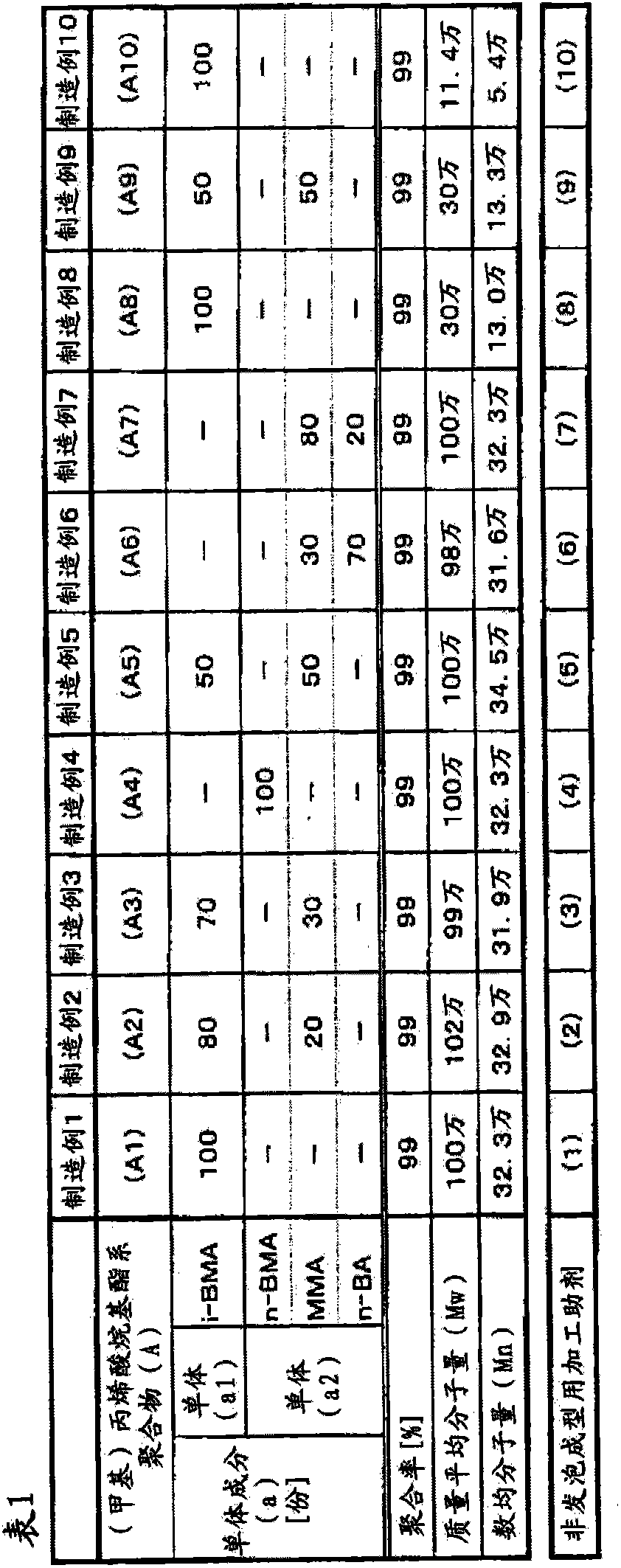

[0103] Except having changed the composition of the monomer component (a) like Table 1, it carried out similarly to manufacture example 1, and produced the alkyl (meth)acrylate type polymer (A). In Table 1, "n-BMA" represents n-butyl methacrylate, "MMA" represents methyl methacrylate, and "n-BA" represents n-butyl acrylate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com