Preparation method of epoxy resin modified waterborne acrylic resin

A technology of water-based acrylic and epoxy resin, applied in the direction of epoxy resin coating, coating, etc., can solve the problems of low gloss and poor adhesion of water-based acrylic resin, so as to improve adhesion and gloss, and improve adhesion The effect of poor and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1, a kind of preparation method of the waterborne acrylic resin modified by epoxy resin, it may further comprise the steps:

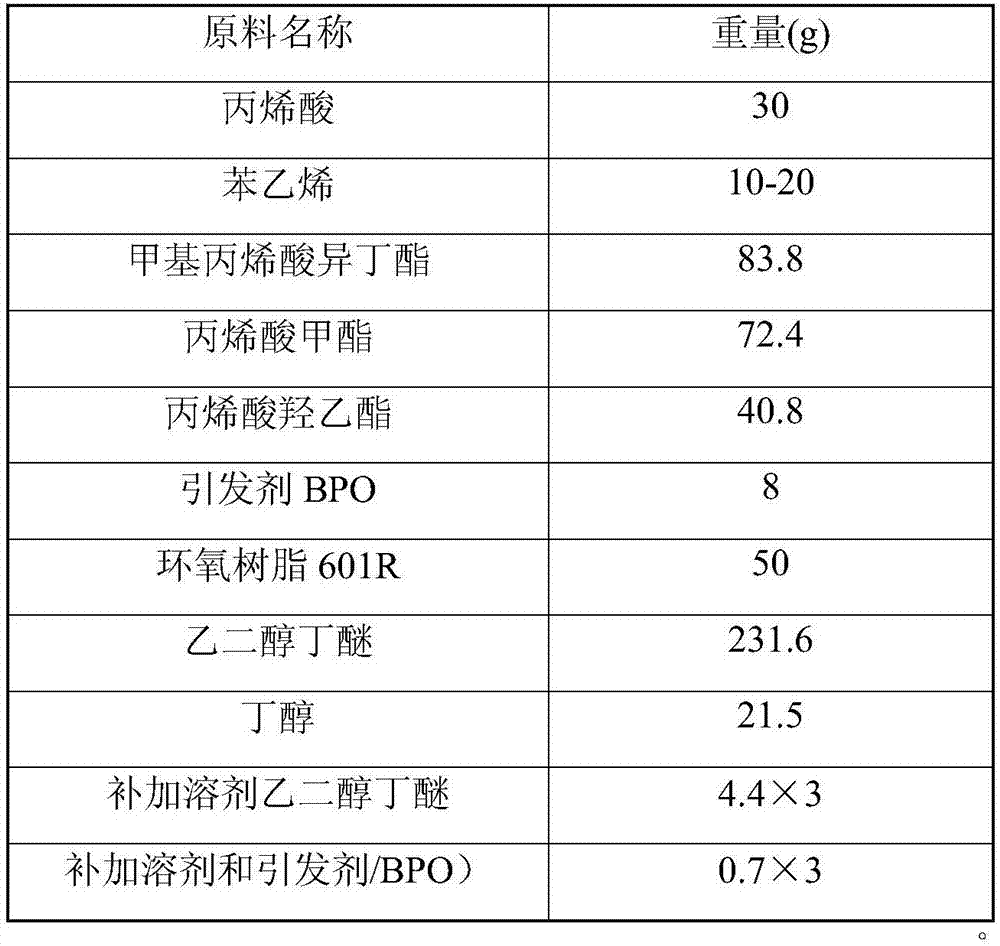

[0024] (1) Add ethylene glycol butyl ether, butanol and epoxy resin 601R of the following table 1 in a four-necked flask equipped with agitator, condenser, thermometer and constant pressure dropping funnel;

[0025] (2) Mix quantitative acrylic acid, styrene, isobutyl methacrylate, methyl acrylate, hydroxyethyl acrylate and initiator dibenzoyl peroxide (BPO) according to Table 1, stir evenly, and drop into the dropping funnel middle;

[0026] (3) After the solvent in the flask is heated to reflux, add the acrylic acid monomer and initiator mixed in step (2) dropwise, and the dropwise addition is completed in about 3.5 hours. Keep the temperature and continue to react for 2 hours, then add 1 part of initiator and 1 part of ethylene glycol butyl ether solvent every 1 hour, and after completing 3 parts of initiator and solvent, a slightly yellowish...

Embodiment 2

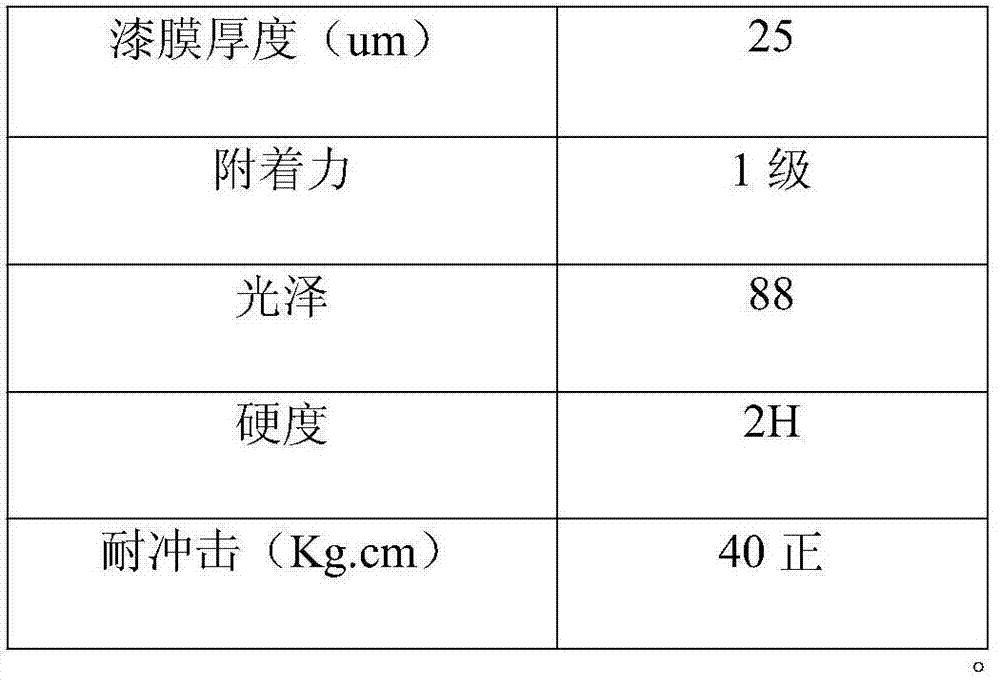

[0030] 1. Put the epoxy resin-modified water-based acrylic resin prepared in Example 1 and the raw material composition in Table 2 into a preparation tank, stir in a sand mill, and after the fineness reaches 20 μm, filter to obtain a resin slurry, and then Add a certain amount of amino resin, water, etc. to prepare water-based acrylic paint. Table 2 Epoxy resin modified waterborne acrylic resin coating formula composition.

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com