Preparation method of glass surface antireflection film without sintering

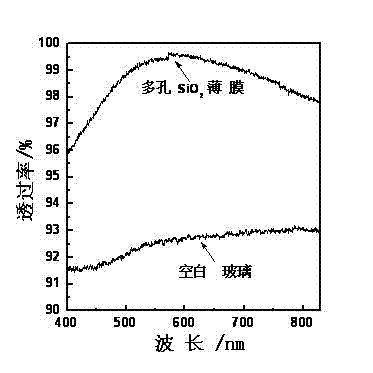

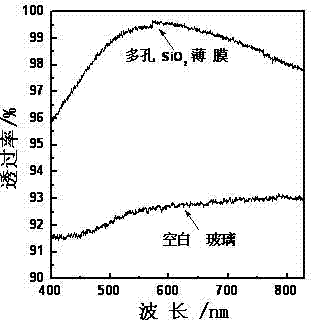

A glass surface and anti-reflection film technology, which is applied in the field of glass surface anti-reflection film preparation, can solve the problems of equipment investment and environmental pollution, increase process difficulty, increase energy consumption, etc., and achieve the effect of high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Example 1: In a dry 100mL beaker, mix 65mL of absolute ethanol, 4.0mL of deionized water, 0.13mL of concentrated hydrochloric acid (37%), and 10mL of ethyl orthosilicate, wherein absolute ethanol: deionized water: concentrated The molar ratio of hydrochloric acid: ethyl orthosilicate is 25:5:0.03:1. Add 2g of cetyltrimethylammonium bromide to the above solution, so that the concentration of cetyltrimethylammonium bromide in the sol is about 25g / L, stir magnetically at room temperature for 8h, and then age for 24h After that, the prepared sol was obtained. Put the 20mm×100mm glass substrate (light transmittance 90%) into 37% hydrochloric acid: 30% hydrogen peroxide: deionized water = 1:1:5 (volume ratio) solution and 37% ammonia water: 30 % Hydrogen peroxide: deionized water = 1:1:5 (volume ratio) Soak in the solution for 2 hours respectively, then fully wash with absolute ethanol and deionized water respectively, and dry in the air. Immerse the treated glass substrate...

Embodiment 2

[0012] Example 2: In a dry 100mL beaker, mix 52mL of absolute ethanol, 2.4mL of deionized water, 0.04mL of concentrated hydrochloric acid (37%), and 10mL of ethyl orthosilicate, wherein absolute ethanol: deionized water: concentrated The molar ratio of hydrochloric acid: ethyl orthosilicate is 20:3:0.01:1. Add 1.3g of dodecyltrimethylammonium bromide to the above solution, so that the concentration of dodecyltrimethylammonium bromide in the sol is about 20g / L, stir magnetically for 4 hours at room temperature, and then age After 24h, the prepared sol was obtained. Put the 20mm×100mm glass substrate (light transmittance 90%) into 37% hydrochloric acid: 30% hydrogen peroxide: deionized water = 1:1:5 (volume ratio) solution and 37% ammonia water: 30 % Hydrogen peroxide: deionized water = 1:1:5 (volume ratio) Soak in the solution for 2 hours respectively, then fully wash with absolute ethanol and distilled water by ultrasonic waves, and dry in the air. Immerse the treated glass ...

Embodiment 3

[0013] Example 3: In a dry 100mL beaker, mix 26mL absolute ethanol, 0.8mL deionized water, 0.44mL concentrated hydrochloric acid (37%), and 10mL tetraethyl orthosilicate, wherein absolute ethanol: deionized water: concentrated The molar ratio of hydrochloric acid: ethyl orthosilicate is 10:1:0.1:1. Add 0.7g of octadecyltrimethylammonium bromide to the above solution, so that the concentration of octadecyltrimethylammonium bromide in the sol is about 20g / L, stir magnetically at room temperature for 8h, and then age After 24h, the prepared sol was obtained. Put the 20mm×100mm glass substrate (light transmittance 90%) into 37% hydrochloric acid: 30% hydrogen peroxide: deionized water = 1:1:5 (volume ratio) solution and 37% ammonia water: 30 % Hydrogen peroxide: deionized water = 1:1:5 (volume ratio) Soak in the solution for 2 hours respectively, then fully wash with absolute ethanol and distilled water by ultrasonic waves, and dry in the air. Immerse the treated glass substrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com