Gasoline for high cleaning vehicle

A technology for cleaning vehicles and gasoline, applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of high saturated vapor pressure, unusable, easy stratification, etc., to overcome the low saturated vapor pressure, overcome the water layer , the effect of high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

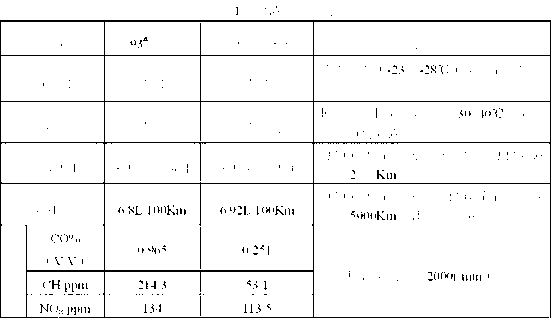

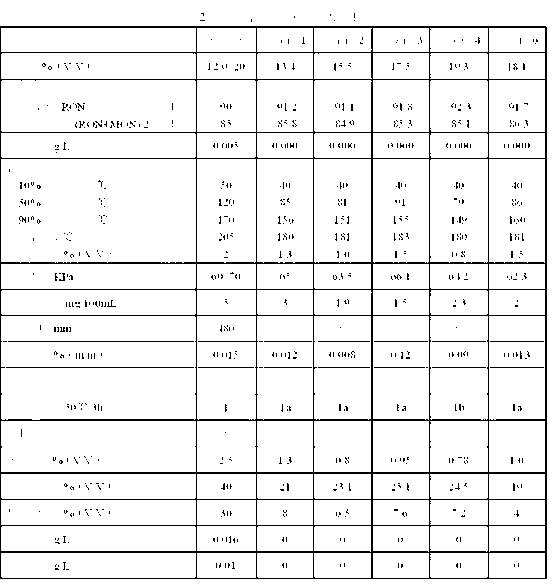

Embodiment 1

[0024] To prepare 1000 liters of high-clean motor gasoline for direct use, the volume ratio is:

[0025] Methylal 150 liters, naphtha 480 liters, aromatic oil 160 liters, mineral spirits 170 liters, MTBE 30 liters, ethylene glycol monoethyl ether 2.8 liters, ethylene glycol monobutyl ether 6.2 liters, 1,6 hexamethylenediamine 0.75 liter, N,N′-disalicylidene-1,2 propanediamine (metal deactivator T1201) 0.25 liter.

[0026] First, stir the additives in a small stirring tank at room temperature for 5-10 minutes, mix well and set aside; add the above additives into the tank containing naphtha, then add MTBE, transfer into solvent oil, and then add methylal and aromatic oil in turn , turn on the oil tank circulation device, and circulate for 5 to 10 minutes to complete the preparation work.

Embodiment 2

[0028] Methylal 170 liters, naphtha 480 liters, aromatic oil 160 liters, mineral spirits 160 liters, MTBE 20 liters, ethylene glycol monoethyl ether 3.0 liters, ethylene glycol monobutyl ether 6.0 liters, 1,6 hexamethylenediamine 0.8 1, 0.20 liters of metal passivator T1201, and the preparation method is the same as in Example 1.

Embodiment 3

[0030] Methylal 190 liters, naphtha 450 liters, aromatic oil 180 liters, mineral spirits 150 liters, MTBE 25 liters, ethylene glycol monoethyl ether 1.33 liters, ethylene glycol monobutyl ether 3.1 liters, 1,6 hexamethylenediamine 0.4 1, 0.17 liters of metal passivator T1201, and the preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com