Method for synthetizing secretion lysozyme by middle silkgland cell of silkworm

A technology of lysozyme and silkworm, applied in the direction of using vectors to introduce foreign genetic material, recombinant DNA technology, animal husbandry, etc., can solve the problems of low benefit, high cost, complicated production process, etc., to improve production efficiency, simplify purification methods, The effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

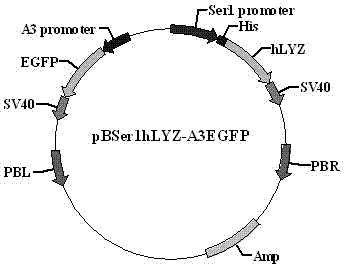

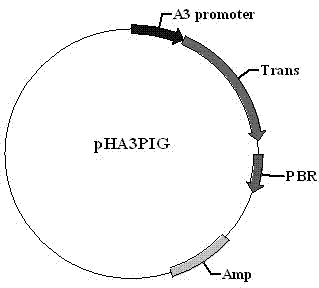

[0019] The pBSer1hLYZ-A3EGFP plasmid ( figure 1 ) and a helper plasmid capable of providing transposase ( figure 2 ) were mixed at a ratio of 5:1, the total concentration of the two plasmids was 0.3 μg / μl, the plasmids were dissolved in 0.1 mM phosphate buffer containing 4 mM sodium chloride, and then introduced into silkworms within 8 hours after spawning by microinjection Into the fertilized eggs, the total volume of introduction is 30nl. The microinjected silkworm eggs were reared to adults at 23°C, 75% humidity, and 8 hours of light, and selfed for successive generations (G1 generation). At the G1 generation silkworm stage of the transgenic experiment, the transgenic silkworm moth 1 expressing the EGFP marker gene was observed and obtained by a fluorescence microscope (Olympus, SZX12, Japan). . The silkworms were reared until the adult and sericin silkworms were crossed to lay eggs for the next generation (G2). The transgenic silkworms after the G2 generation were all...

Embodiment 2

[0022] The pBSer1hLYZ-A3EGFP plasmid ( figure 1 ) and a helper plasmid capable of providing transposase ( figure 2 ) were mixed at a ratio of 1:1, the total concentration of the two plasmids was 1 μg / μl, the plasmids were dissolved in 2 mM phosphate buffer containing 1 mM sodium chloride, and then introduced into silkworm fertilization within 6 hours after egg laying by microinjection In ovo, the total volume of introduction was 5nl. The microinjected silkworm eggs were reared to adults at 28°C, 90% humidity, and 12 hours of light, and the transgenic silkworms were self-bred for successive generations (G1 generation). At the G1 generation silkworm stage of the transgenic experiment, the transgenic silkworm moth 1 expressing the EGFP marker gene was observed by a fluorescence microscope (Olympus, SZX12, Japan). . The silkworms were reared until the adult and sericin silkworms were crossed to lay eggs for the next generation (G2). The transgenic silkworms after the G2 gener...

Embodiment 3

[0025] The pBSer1hLYZ-A3EGFP plasmid ( figure 1 ) and a helper plasmid capable of providing transposase ( figure 2) were mixed at a 2:1 ratio, the total concentration of the two plasmids was 0.5 μg / μl, the plasmids were dissolved in 1 mM phosphate buffer containing 2 mM sodium chloride, and then introduced into silkworms within 4 hours after spawning by microinjection In fertilized eggs, the total volume of introduction is 15nl. The microinjected silkworm eggs were reared to adults at 25°C, 80% humidity, and 12 hours of light, and then mated with non-transgenic silkworms (G1 generation). At the G1 generation silkworm stage of the transgenic experiment, the transgenic silkworm moth 1 expressing the EGFP marker gene was observed by a fluorescence microscope (Olympus, SZX12, Japan). . The silkworms were reared until the adult and sericin silkworms were crossed to lay eggs for the next generation (G2). The transgenic silkworms after the G2 generation were all bred by single m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Excitation wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com