Method for producing microencapsulated starter diet for Trachinotus ovatus fries

A production method and a technology of open feed, which is applied in the production field of microcapsule open feed for golden pomfret fry less than or equal to 1.8 cm, can solve the problems of no golden pomfret fry, many fish diseases, and polluted water quality, so as to facilitate feeding and easy supermicro Crushed, easy to digest and absorb

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

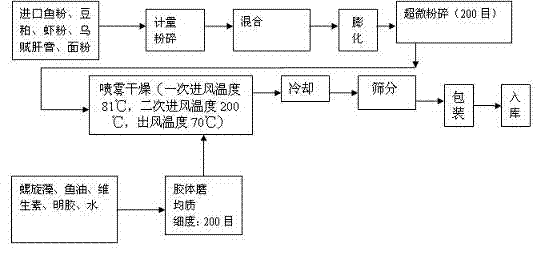

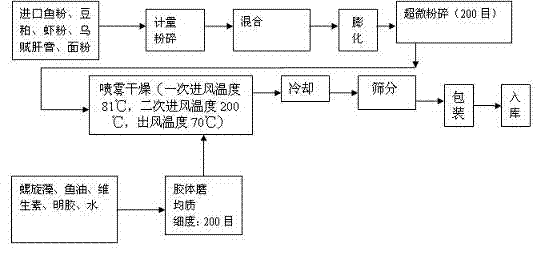

[0015] Crush 500 kg of imported fish meal, 160 kg of soybean meal, 60 kg of shrimp meal, 45 kg of squid liver paste, 220 kg of flour, and 15 kg of minerals (phosphorus or zinc) into 80 meshes and enter the puffing machine for pretreatment. After puffing pretreatment, it is superfinely pulverized to 200 mesh, and the pulverized thing is the core material.

[0016] Then 15 kg of spirulina, 20 kg of fish oil, 1.5 kg of vitamins (vitamin A or vitamin B), 45 kg of gelatin, and 418.5 kg of water were mixed and homogenized by colloid milling to a fineness of 200 mesh, and used as wall material coating; Microcapsule bait was made by spray drying method. When preparing microcapsule bait, the ratio of wall material (cured material) to core material is 1:100. The most commonly used method for making microencapsulated bait is the spray drying method. The first air inlet temperature is 81°C for 10-15 minutes, the second air inlet temperature is 200°C for 8-10 minutes, and the outlet air ...

Embodiment 2

[0018] 55 kg of imported fish meal, 13 kg of soybean meal, 5 kg of shrimp powder, 5 kg of squid liver paste,

[0019] 21 kg of flour and 1 kg of minerals (iron or copper or manganese) are pulverized to 80 mesh and enter the puffing machine for puffing pretreatment. After puffing pretreatment, it is superfinely pulverized to 200 mesh, and the pulverized thing is the core material. Then mix 1 kg of spirulina, 2 kg of fish oil, 0.1 kg of vitamins (vitamin C), 4 kg of gelatin, and 42.9 kg of water, and pass through a colloid mill with a fineness of 200 mesh to make the wall material coating; use spray drying The method is made into microcapsule bait. When preparing microcapsule bait, the ratio of wall material (cured material) to core material is 10:100. The most commonly used method for making microencapsulated bait is the spray drying method. The first air inlet temperature is 81°C for 10-15 minutes, the second air inlet temperature is 200°C for 8-10 minutes, and the outlet ai...

Embodiment 3

[0021] Crush 50 kg of imported fish meal, 14 kg of soybean meal, 6 kg of shrimp meal, 5.5 kg of squid liver paste, 23 kg of flour, and 1.5 kg of minerals (selenium or cobalt) to 80 mesh and enter the puffing machine for pretreatment. After puffing pretreatment, it is superfinely pulverized to 200 mesh, and the pulverized thing is the core material. Then mix 1.5 kg of spirulina, 1.5 kg of fish oil, 0.1 kg of vitamin (vitamin D), 4 kg of gelatin, and 42.9 kg of water, and pass through a colloid mill with a fineness of 200 mesh to make the wall material coating; use spray drying The method is made into microcapsule bait. When preparing microcapsule bait, the ratio of wall material (cured product) to core material is 5:100.100. The most commonly used method for making microencapsulated bait is the spray drying method. The first air inlet temperature is 81°C for 10-15 minutes, the second air inlet temperature is 200°C for 8-10 minutes, and the outlet air temperature is 70°C for 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com