SDFGD (semi-dry flue gas desulfurization) device

A desulfurization device and semi-dry technology, applied in the field of environmental engineering, can solve the problems of insufficient utilization of desulfurizer, short residence time of flue gas, high maintenance frequency, etc., and achieve uniform mixing, saving power consumption and maintenance costs, The effect of low running cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

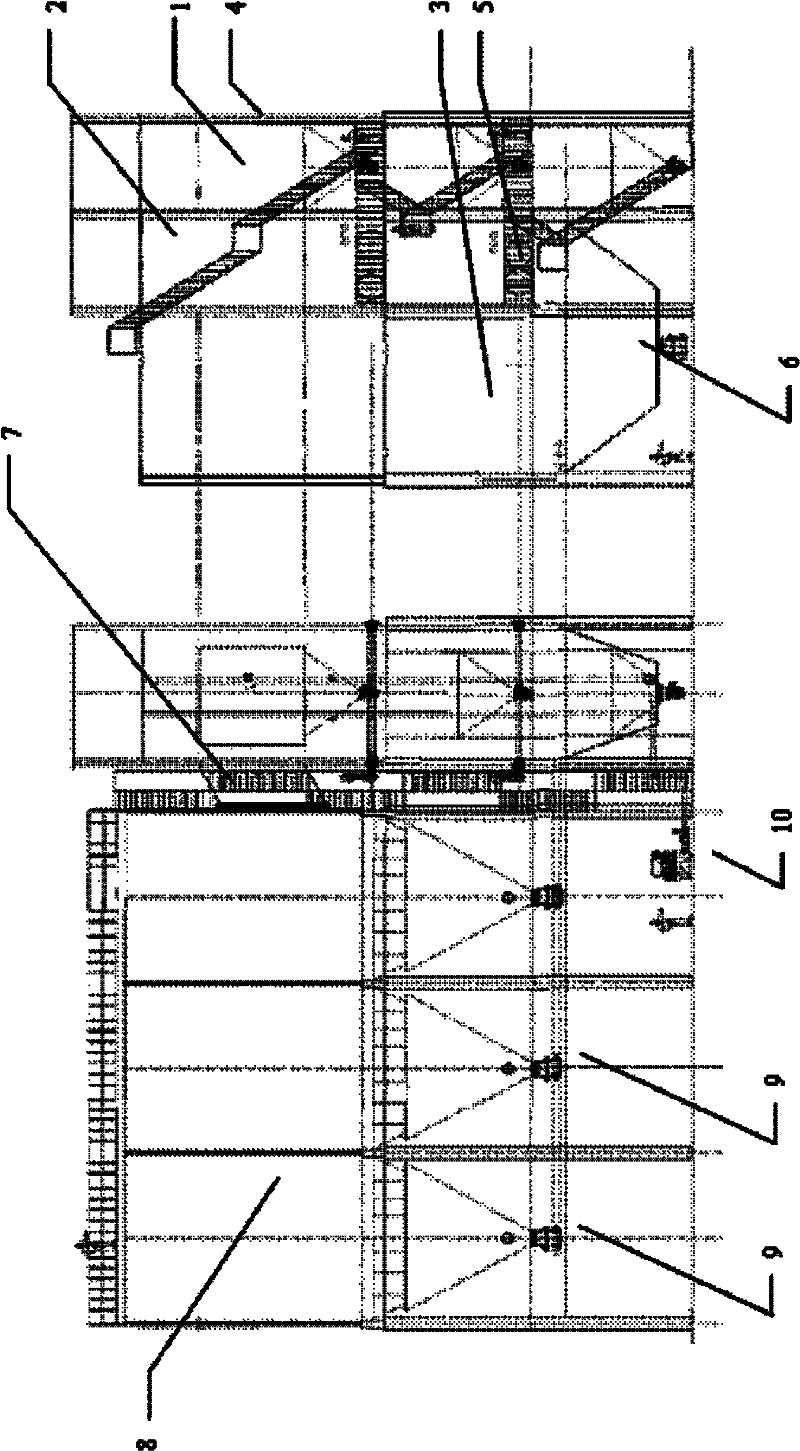

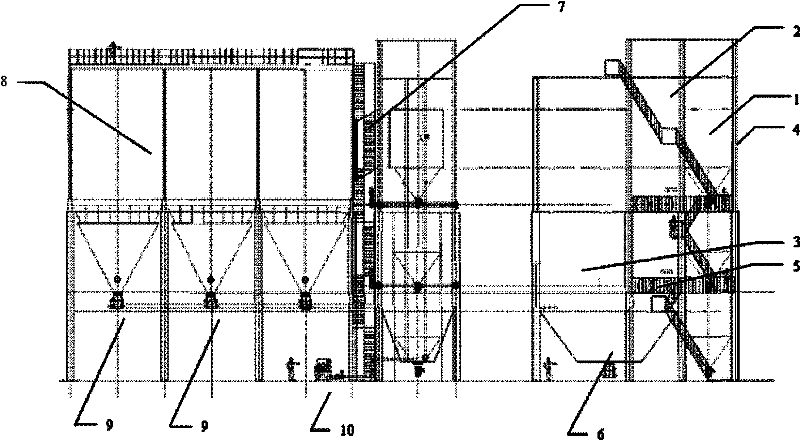

[0025] The specific implementation process of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] In the present invention, the flue gas inlet 4 is set at the right outer 1 / 4 height of the winnowing chamber 1, and the flue gas enters the winnowing chamber at an angle of 90 degrees. The flue gas reacts with the activated desulfurizer in the winnowing chamber 1. The fine and highly active particles enter the dense phase chamber 2 from the upper part and continue to react after being humidified. Some coarse particles fall directly into the dense phase chamber 2 from below. The flue gas flows from top to bottom in the dense phase chamber 2, the larger particles fall into the ash hopper 6 at the bottom of the dense phase chamber 2, and the fine particles enter the circulating fluidized chamber 3 from the bottom together with the flue gas. After being uniformly fluidized by the external Roots blower 10 in the circulating fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com