Application of polymer additive M4228 in preparing copolypropylene tubing

A technology for copolymerizing polypropylene and polypropylene pipes, which is applied in the direction of pipes, rigid pipes, mechanical equipment, etc., which can solve the problems of large thermal expansion coefficient and low notched impact strength, and achieve good mechanical properties, good water extraction resistance, and long service life Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

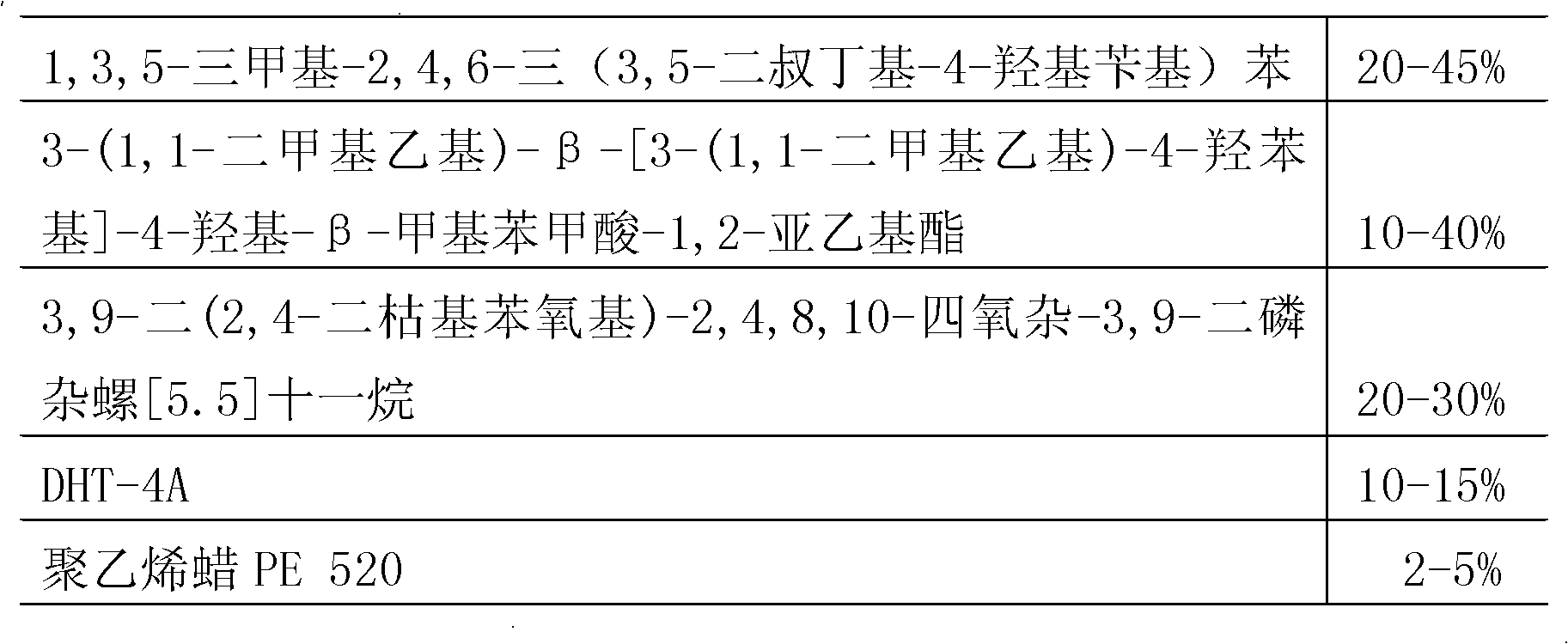

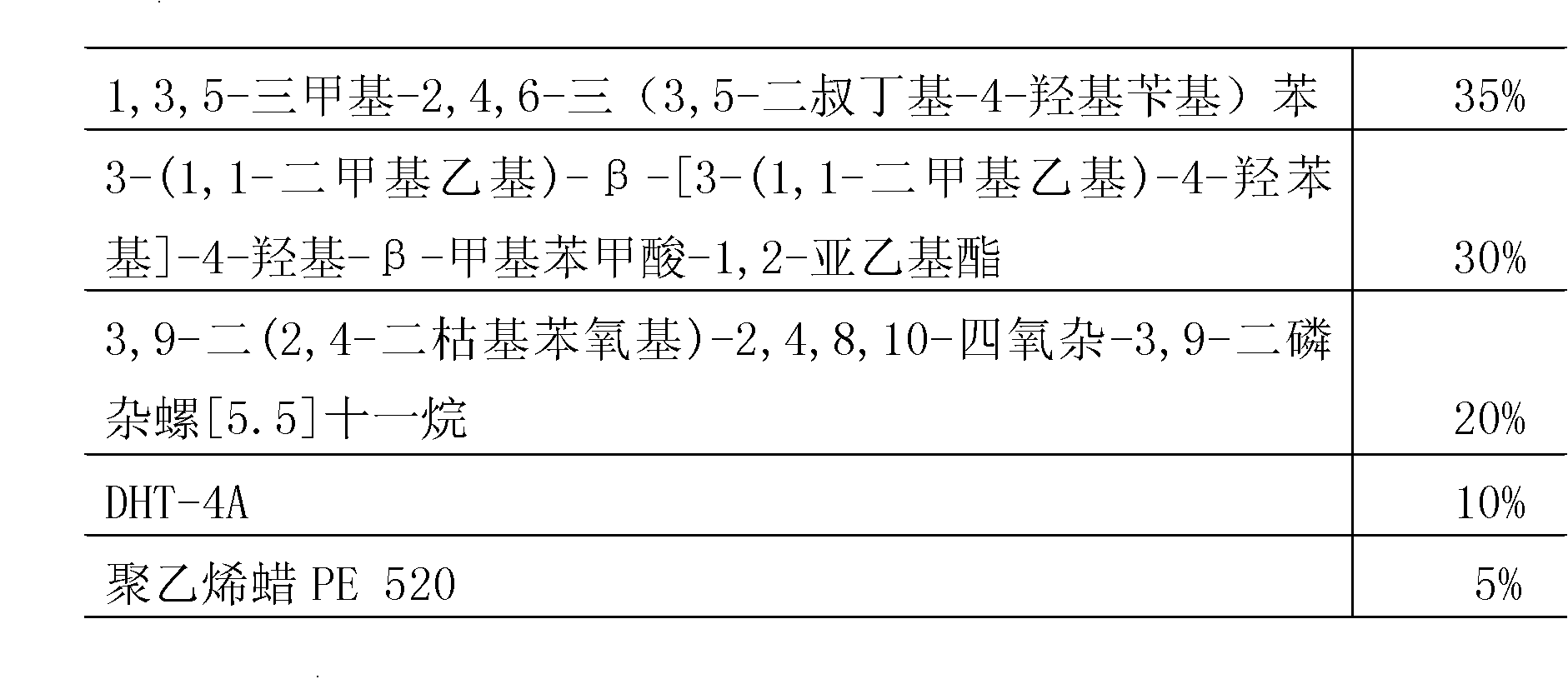

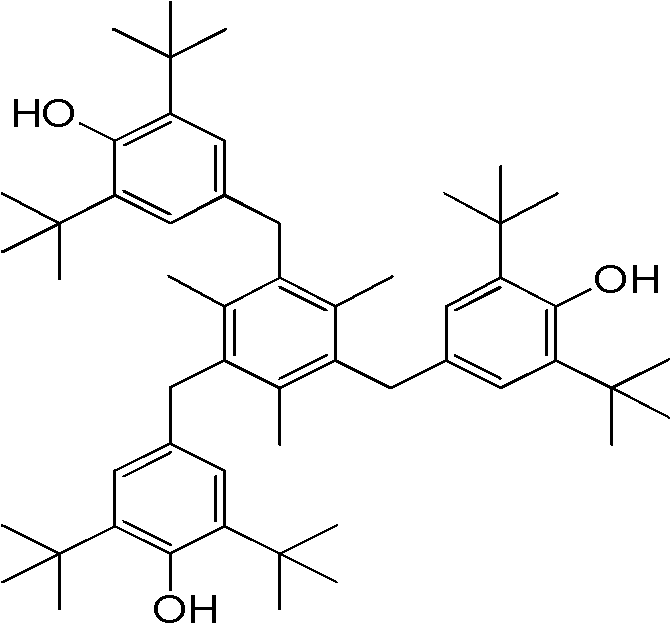

[0025] Preparation of polymer additive M4228:

[0026] 1,3,5-trimethyl-2,4,6-tri(3,5-di-tert-butyl-4-hydroxybenzyl)benzene is 35 parts; 3-(1,1-dimethylethyl )-β-[3-(1,1-dimethylethyl)-4-hydroxyphenyl]-4-hydroxy-β-methylbenzoic acid-1,2-ethylene ester is 30 parts; 3 , 20 parts of 9-bis(2,4-dicumylphenoxy)-2,4,8,10-tetraoxa-3,9-diphosphaspiro[5.5]undecane; DHT-4A 10 parts of polyethylene wax; 5 parts of polyethylene wax; after mixing and stirring the above components for 30 minutes, under the protection of nitrogen, heat at 1 atmosphere pressure and 180 ° C, stir each component in a molten state for 30 minutes, and cool the obtained product Pass through a 200-mesh sieve after crushing, and collect the part under the sieve to obtain the polymer additive M4228 of the present invention.

Embodiment 2

[0028] The random copolymerization pipe base powder (weight average molecular weight M W : 596000, molecular weight distribution (M W / M N )=4.8, ethylene content (wt%): 3.2) and polymer additive M4228 (prepared by embodiment 1) after fully mixing by the mass ratio of 100:0.7, add twin-screw extruder, with 30-40 tons / The extrusion speed of h is extruded. The reaction temperature of each section of the screw is 200°C, 220°C, 230°C, 250°C, 270°C, 270°C, 270°C, 260°C, 250°C, 230°C.

Embodiment 3

[0030] Block copolymerized pipe base powder (weight average molecular weight M W : 519000, molecular weight distribution (M W / M N )=4.8, ethylene content (wt%): 16.3) and polymer additive M4228 (prepared by embodiment 1) after fully mixing by the mass ratio of 100:0.7, add twin-screw extruder, with 30-40 tons / The extrusion speed of h is extruded. The reaction temperature of each section of the screw is 200°C, 220°C, 230°C, 250°C, 270°C, 270°C, 270°C, 260°C, 250°C, 230°C.

[0031] The pipe material that embodiment 2,3 produce is carried out the test of mechanical property as shown in the following table:

[0032] The contrast of table 1 embodiment 2,3 and the mechanical property of comparative sample

[0033]

[0034]

[0035] Note: Comparative sample 1 is C4220 tube material, and comparative sample 2 is B8101 tube material.

[0036] It can be seen from the above table that the polypropylene pipe material products produced by using this polymer additive M4228 fully...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| oxidation induction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com