Heat-insulating integral compound brick with lutaceous structure and preparation method

A composite brick and clay-based technology, applied in the field of refractory materials, can solve the problems of high thermal conductivity, poor structural strength, poor thermal insulation performance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Clay structure heat insulation integrated composite brick

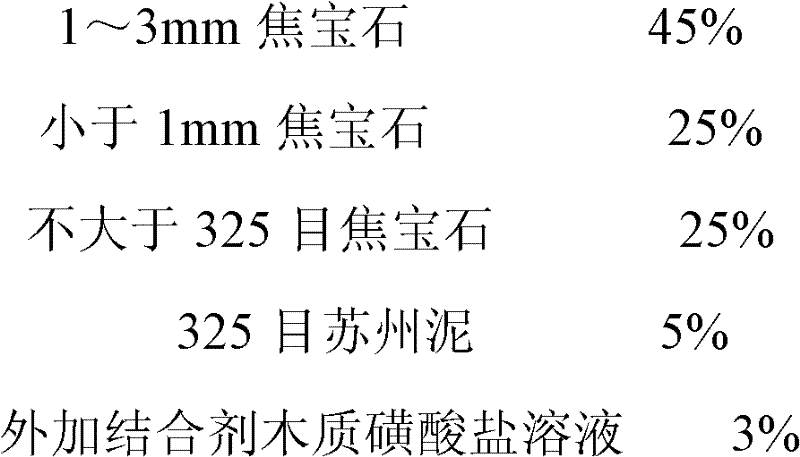

[0034] The raw materials and mass percentages thereof used in the heavy working layer of this embodiment are:

[0035]

[0036] Among them, the grade of coke gem is YNS36.

[0037] According to the above proportioning ratio, the mass percentage of the obtained heavy working layer composition Al 2 o 3 43%, SiO 2 52.4%, and the rest are other ingredients introduced by raw materials.

[0038]The raw materials and their mass percentages used in the lightweight heat insulation layer are: 40% corundum hollow balls, 30% floating beads, 25% coke gems not larger than 325 mesh, 5% 325 mesh Suzhou mud, plus binder paper pulp waste Liquid 6%; among them, the mass percentage content of Al in corundum hollow spheres 2 o 3 It is 96%; the mass percentage content of Al in floating beads 2 o 3 25%, SiO 2 65%.

[0039] The manufacturing method of clay structure heat insulation integrated composite brick c...

Embodiment 2

[0045] Example 2: Clay structure heat insulation integrated composite brick

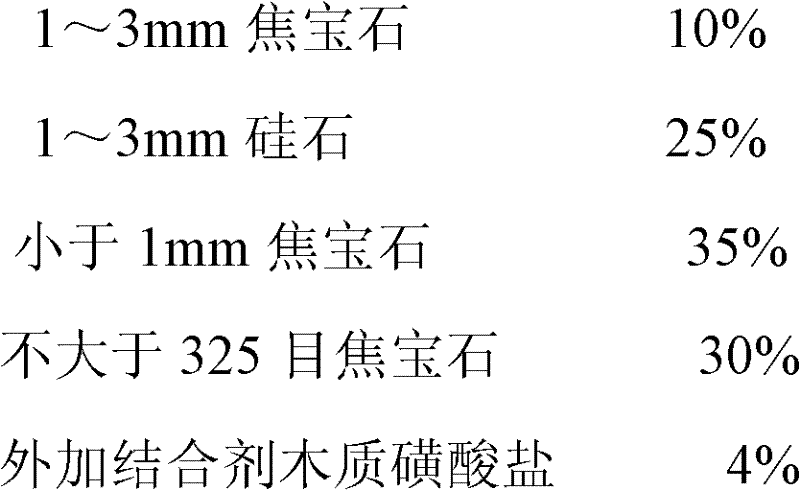

[0046] The raw materials and mass percentages thereof used in the heavy working layer of this embodiment are:

[0047]

[0048] Among them, the grade of coke gem is YNS36, and the grade of silica is GS-98.5.

[0049] According to the above proportioning ratio, the mass percentage of the obtained heavy working layer composition Al 2 o 3 It is 30%, silicon oxide is 65%, and the rest are other components introduced by raw materials.

[0050] The raw materials and their mass percentages used in the lightweight heat insulation layer are: 45% lightweight high-alumina aggregate, 15% lightweight ceramsite, 40% coke gemstones not larger than 325 mesh, and methyl fiber as a binder 7% plain solution; among them, the mass percentage content of Al in the lightweight high alumina aggregate 2 o 3 70%, the mass percentage content of Al in lightweight ceramsite 2 o 3 It is 18% and silicon oxide is 65%.

[...

Embodiment 3

[0057] Example 3: Clay structure heat insulation integrated composite brick

[0058] The raw materials and mass percentages thereof used in the heavy working layer of this embodiment are:

[0059]

[0060] Among them, the grade of coke gem is YNS36.

[0061] According to the above proportioning ratio, the mass percentage of the obtained heavy working layer composition Al 2 o 3 42%, SiO 2 It is 47.5%, and the rest are other ingredients introduced by raw materials.

[0062] The raw materials and their mass percentages used in the lightweight heat insulation layer are: 30% corundum hollow balls, 25% lightweight mullite aggregates, 35% coke powder not larger than 325 mesh, 10% 325 mesh Liuzhou mud , plus 10% of the binder lignosulfonate solution; wherein the mass percentage of the composition in the corundum hollow sphere is Al 2 o 3 96%, the mass percentage of Al in the lightweight mullite aggregate 2 o 3 was 74%.

[0063] The manufacturing method of clay structure he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com