Ultraviolet-thermal curable coating

A dual-curing, ultraviolet technology, applied in the field of coatings, can solve the problems of uncurable shadow areas, difficult curing of colored systems, and limitation of light wave transmission ability in curing depth, etc., to achieve good deep curing effect, good deep curing effect, and resistance to cold and heat good shock effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

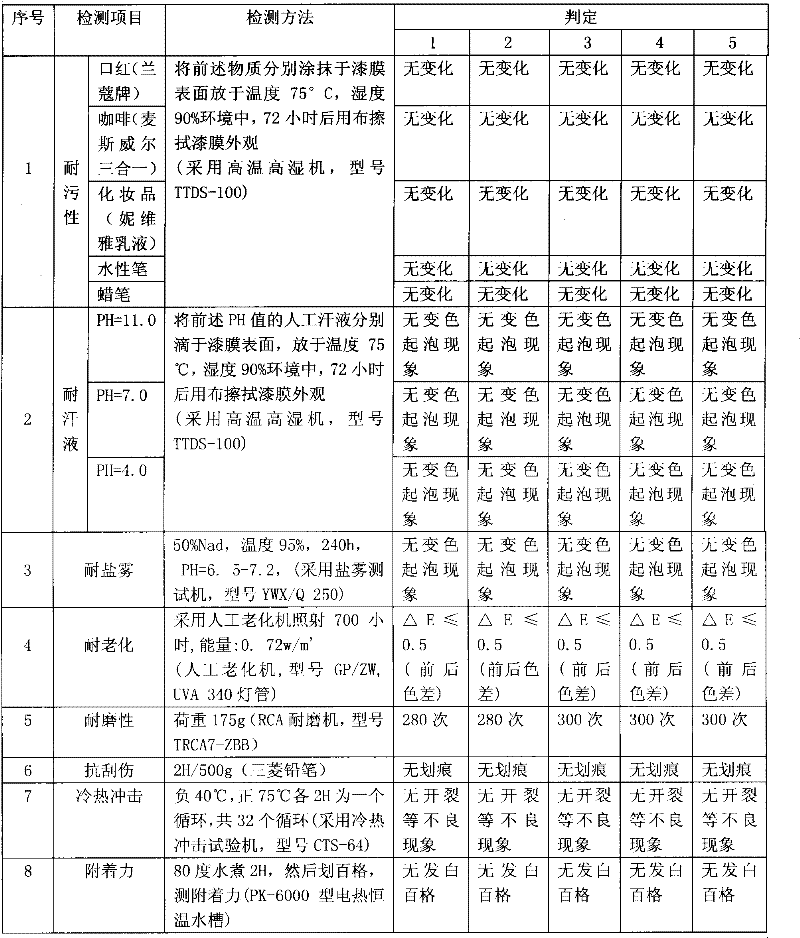

Examples

Embodiment 1

[0035] Embodiment 1: A kind of UV-heat dual-curing coating is prepared from the following raw materials in mass percentage:

[0036] Hexafunctional Aliphatic Urethane Acrylate 12.5%

[0037] Difunctional aliphatic urethane acrylate with 15% PGDA 5%

[0038] Hydroxy Acrylic Resin 10%

[0039] Trimethylolpropane Triacrylate 4%

[0040] Tripropylene glycol diacrylate 3%

[0041] 1-Hydroxy-cycloethyl-phenyl ketone 1.4%

[0042] 2.4.6 Diphenyl phosphorus oxide 0.4%

[0043] Silicone leveling agent 0.4%

[0044] Silicone-containing defoamer 0.1%

[0046] Aliphatic urethane acrylate containing NCO groups 3.2%.

[0047] Wherein, the inert solvent is composed of diacetone alcohol, butyl ester and ethyl ester, and the mass ratio of diacetone alcohol, butyl ester and ethyl ester is 2:5:3.

Embodiment 2

[0048] Embodiment 2: A kind of UV-heat dual-curing coating is prepared from the following raw materials in mass percentage:

[0049] Hexafunctional Aliphatic Urethane Acrylate 15%

[0050] Difunctional aliphatic urethane acrylate with 15% PGDA 10%

[0051] Hydroxy Acrylic Resin 12.5%

[0052] Trimethylolpropane Triacrylate 8%

[0053] Tripropylene glycol diacrylate 6%

[0054] 1-Hydroxy-cycloethyl-phenyl ketone 3.5%

[0055] 2.4.6 Diphenyl phosphorus oxide 1%

[0056] Silicone leveling agent 0.6%

[0057]Silicone-containing defoamer 0.2%

[0058] Inert solvent 40%

[0059] Aliphatic urethane acrylate containing NCO groups 3.2%.

[0060] Wherein, the inert solvent is composed of diacetone alcohol, butyl ester and ethyl ester, and the mass ratio of diacetone alcohol, butyl ester and ethyl ester is 2:5:3.

Embodiment 3

[0061] Embodiment 3: A kind of UV-heat dual-curing coating is prepared from the following raw materials in mass percentage:

[0062] Hexafunctional Aliphatic Urethane Acrylate 12.5%

[0063] Difunctional aliphatic urethane acrylate with 15% PGDA 5%

[0064] Hydroxy Acrylic Resin 12.5%

[0065] Trimethylolpropane Triacrylate 10%

[0066] Tripropylene glycol diacrylate 7.5%

[0067] 1-Hydroxy-cycloethyl-phenyl ketone 1.75%

[0068] 2.4.6 Diphenyl phosphorus oxide 0.5%

[0069] Silicone leveling agent 0.2%

[0070] Silicone-containing defoamer 0.05%

[0071] Inert solvent 45%

[0072] Aliphatic urethane acrylate containing NCO groups 5%.

[0073] Wherein, the inert solvent is composed of diacetone alcohol, butyl ester and ethyl ester, and the mass ratio of diacetone alcohol, butyl ester and ethyl ester is 2:5:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com