Oil displacement agent

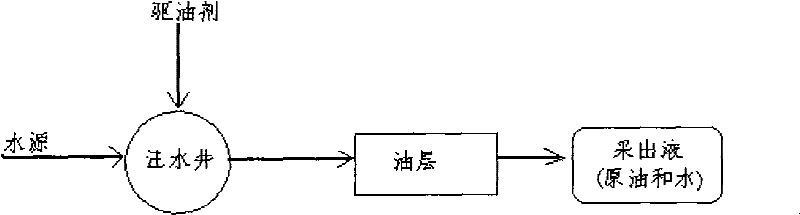

A technology of oil-displacement agent and main agent, which is applied in the field of oil-displacement agent for tertiary oil recovery. It can solve problems such as formation blockage, harsh polymer flooding conditions, and damage to oil displacement rate, so as to save costs, increase oil recovery, and improve utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] raw material:

[0031] 30% hydrogen peroxide aqueous solution (hydrogen peroxide) 60g, water 40g

[0032] Usage method: mix 60g of 30% hydrogen peroxide aqueous solution (hydrogen peroxide) and 40g of water, stir, then dilute to a concentration of 1%, and inject into the water injection well.

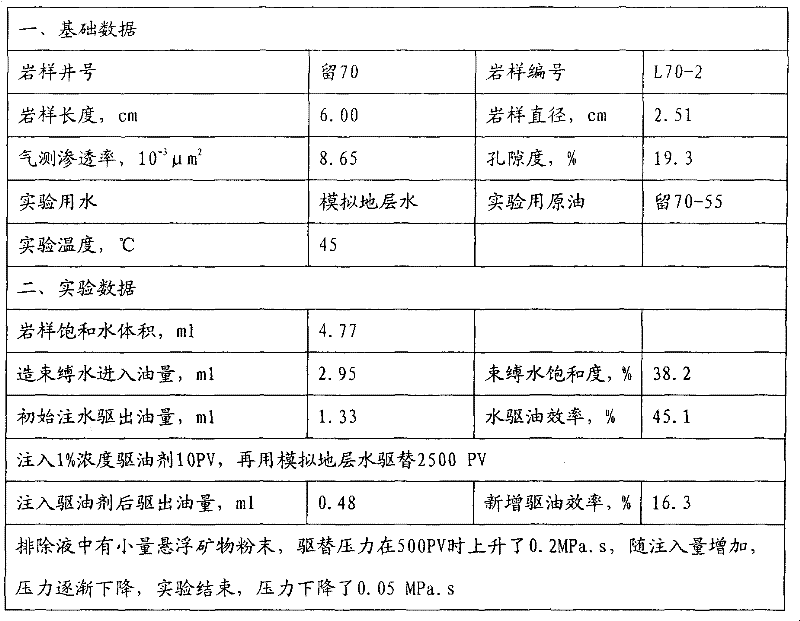

[0033] Experimental results:

[0034]

Embodiment 2

[0036] raw material:

[0037] 0.25% concentration of chlorine peroxide (chlorine dioxide) aqueous solution 30g, alkylphenol polyoxyethylene ether 5g, water 65g

[0038] Usage method: Mix 30g of 0.25% chlorine peroxide (chlorine dioxide) aqueous solution, 5g of alkylphenol polyoxyethylene ether and 65g of water, stir, then dilute to a concentration of 5%, and inject into the water injection well.

[0039] Experimental results:

[0040]

[0041]

Embodiment 3

[0043] raw material:

[0044] Sodium permanganate 10g, 20% concentration of dodecyl dimethyl betaine 15g, water 75g

[0045] Usage method: Mix 10g of sodium permanganate, 15g of dodecyl dimethyl betaine at a concentration of 20% and 75g of water, stir, then dilute to a concentration of 2%, and inject into the water injection well.

[0046] Experimental results:

[0047]

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com