High-power narrow-pulse laser light source

A technology of laser light source and narrow pulse, which is applied in the field of laser light source, can solve the problems of low precision, small optical peak power, poor stability, etc., and achieve the effect of high adjustment accuracy, adjustable repetition frequency and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation steps of the present invention will be further described below in conjunction with the accompanying drawings.

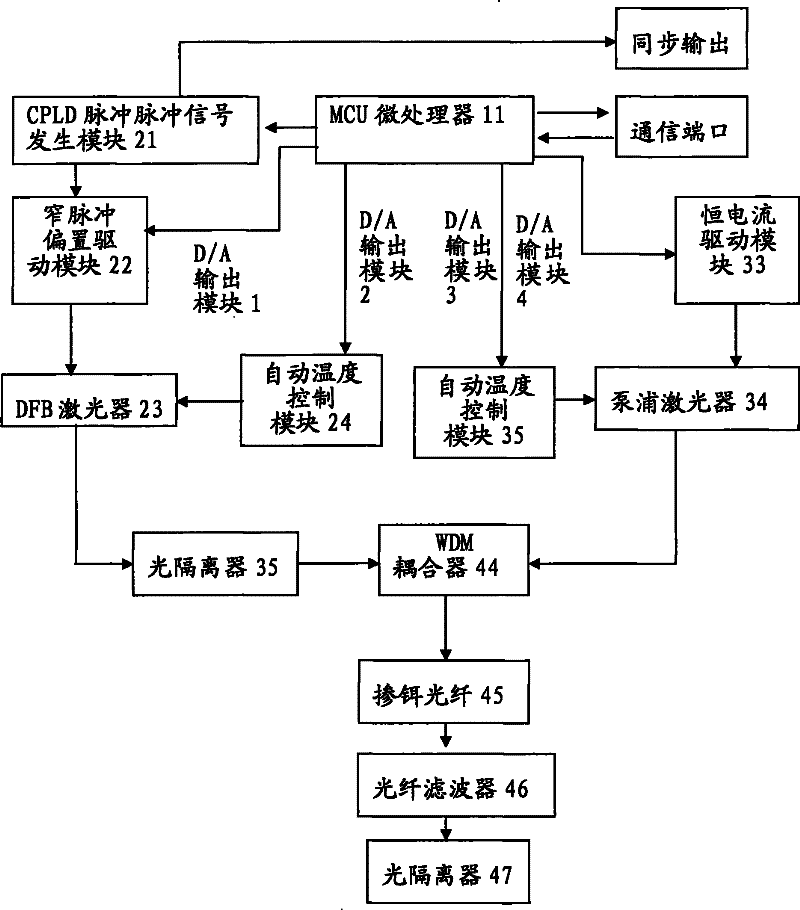

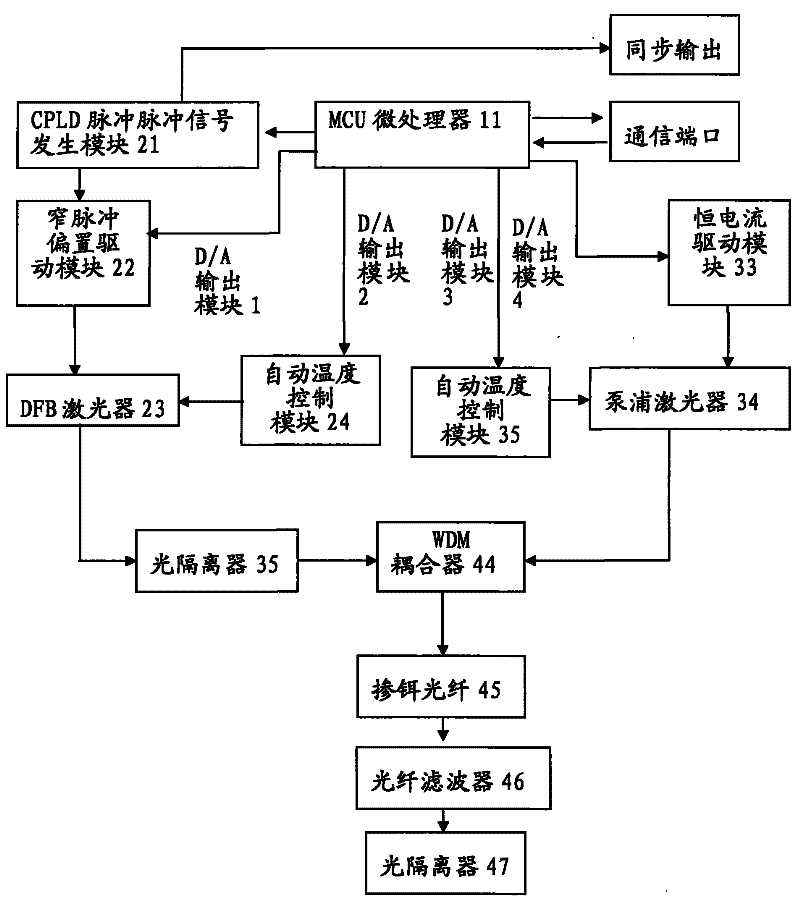

[0039] In this embodiment, the schematic diagram of the system structure of the high-power narrow-pulse laser light source 1 is as follows: figure 1 As shown, it includes CPLD pulse signal generation module 21, MCU microprocessor 11, narrow pulse bias drive module 22, constant current drive module 33, DFB laser 23, automatic temperature control module 24, pump laser 34, automatic temperature control module 35. WDM coupler 44, optical isolator 35, erbium-doped fiber 45, optical fiber filter 46, optical isolator 47 and communication interface.

[0040] The high-power narrow-pulse laser light source 1 includes a bidirectional communication interface, a pulse synchronization interface and an optical output terminal.

[0041] The laser light source includes an optical output end for outputting a hundred-watt-level high-power optical pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com