On-chip integrated high repetition frequency laser resonant cavity device and ultrashort pulse laser

A laser resonator, pulsed laser technology, applied in the structure/shape of optical resonators, lasers, laser parts and other directions, can solve the problems of optical fiber mode mismatch, easy to be interfered by the outside world, etc., to improve reliability, not easy to external Interference, improve the effect of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

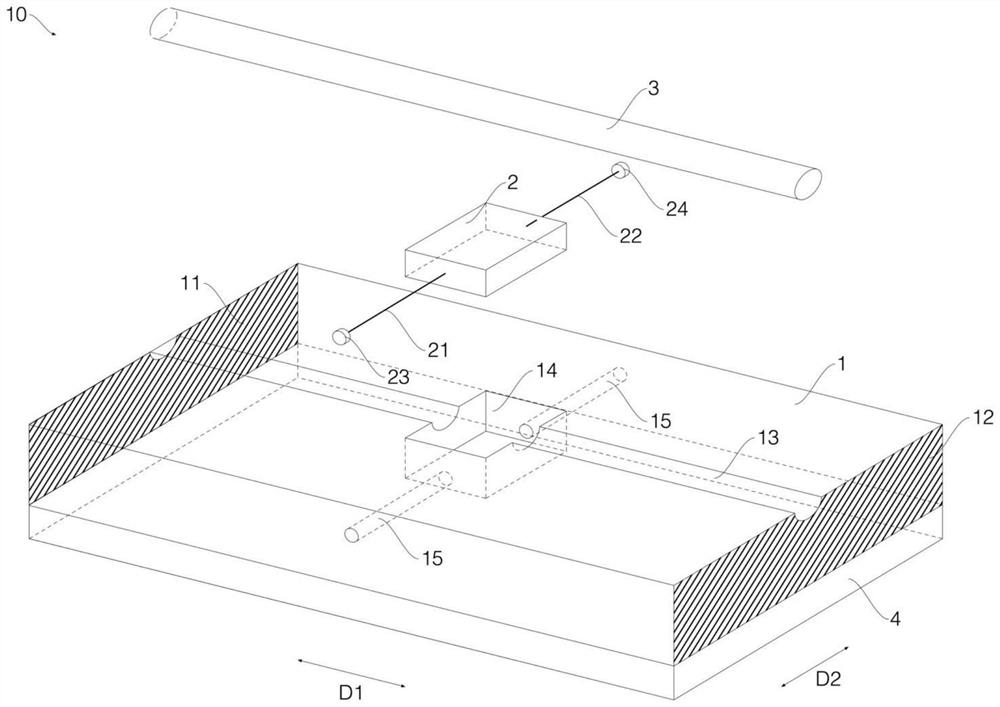

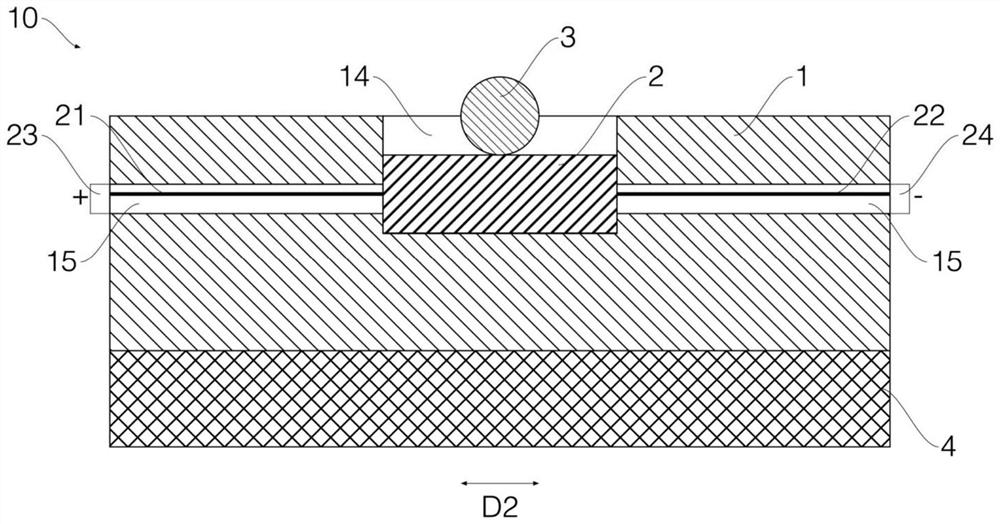

[0049] see figure 1 and figure 2 , figure 1 and figure 2 The on-chip integrated high repetition frequency laser resonator device 10 in Embodiment 1 is shown. It should be noted that, figure 1 and figure 2 The size of each component of the on-chip integrated high repetition frequency laser resonator device 10 does not reflect the actual size of each component in this embodiment, but is only for illustrating the structure of each component. The real size of each component in this embodiment should be subject to the written description.

[0050] Such as figure 1 and figure 2 As shown, the on-chip integrated high repetition frequency laser resonator device 10 in Embodiment 1 includes a semiconductor substrate 1 , a piezoelectric actuator 2 , a gain fiber 3 and a temperature regulator 4 .

[0051] In the present embodiment, the semiconductor substrate 1 adopts a silicon wafer, and its size is 50 mm along the length of the first direction D1, and 50 mm along the width of...

Embodiment 2

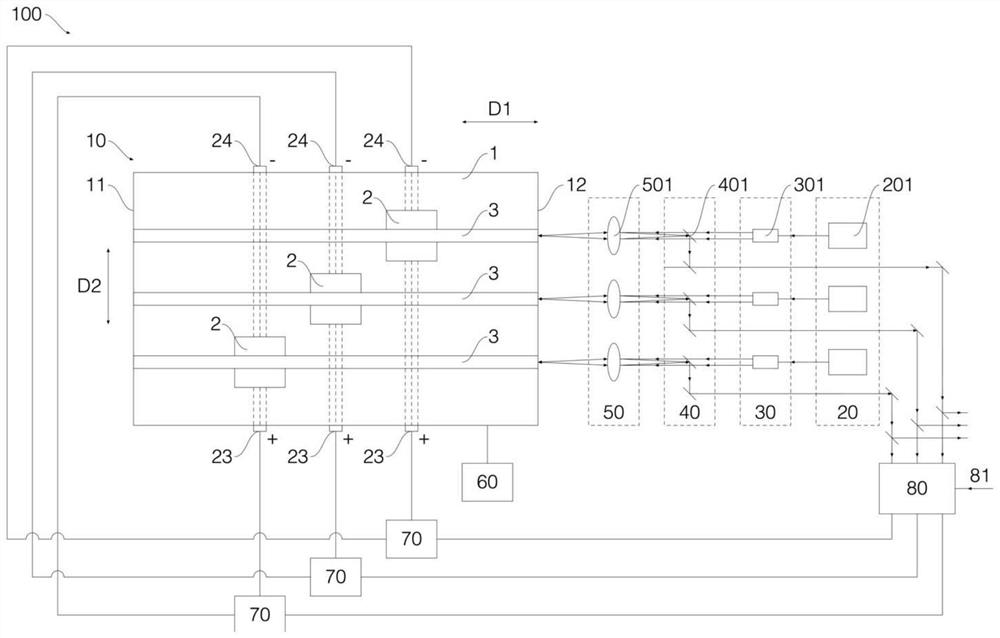

[0069] see image 3 , image 3 shows the ultrashort pulse laser 100 in the second embodiment, as image 3 As shown, the ultrashort pulse laser 100 includes an on-chip integrated high repetition rate laser resonator device 10 , a pump laser generation system 20 , a coupling system, a temperature controller 60 , three voltage regulators 70 and a repetition rate controller 80 .

[0070] Among them, such as image 3 As shown, the on-chip integrated high repetition frequency laser resonator device 10 includes a semiconductor substrate 1, three piezoelectric actuators 2, three gain fibers 3 and a temperature regulator 4 ( image 3 not shown).

[0071] Wherein, the semiconductor substrate 1 is a silicon wafer, and its two ends along the first direction D1 are respectively provided with a semiconductor saturable absorption mirror 11 and a dichroic dielectric film 12 . The semiconductor saturable absorption mirror 11 and the dichroic dielectric film 12 are the same as those in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com