High-performance laminated veneer lumber panel and production method thereof

A veneer lamination and production method technology, applied in the direction of layered products, wooden veneer joints, chemical instruments and methods, etc., can solve problems such as high cost, low mechanical properties, and large variability of wood veneers. Achieve the effects of improving bending and wear resistance, improving dimensional stability, and adding bending-resistant reinforcement layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Production of laminated veneer lumber (LVL) by grading and partial impregnation of veneers

[0034] For the imported North American twisted leaf pine, the veneer with a thickness of 3.2mm is obtained by rotary cutting, and dried to a moisture content of 3-6%.

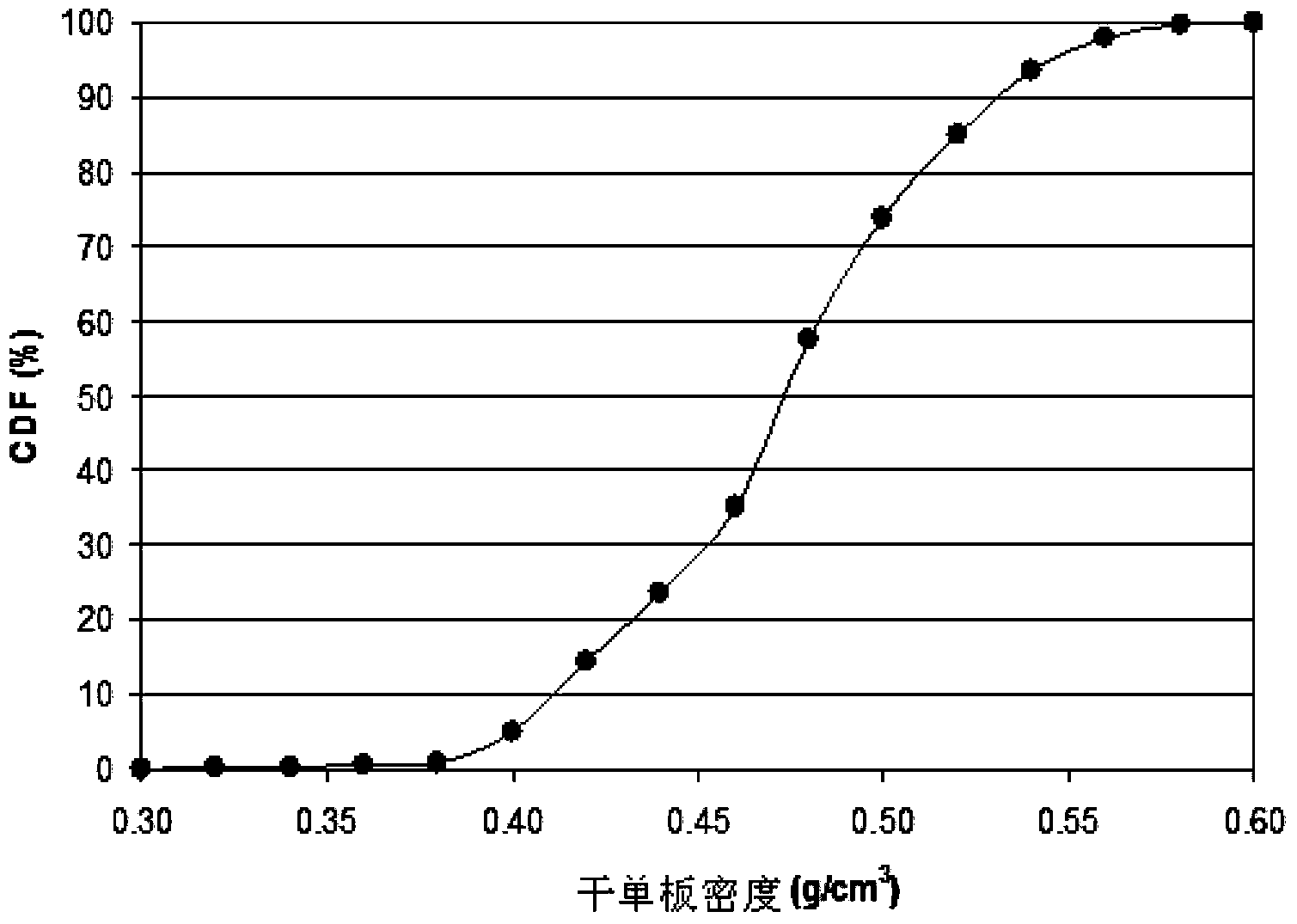

[0035] Before the veneer is graded, the density ρ range of the veneer is determined to be 0.3g / cm 3 to 0.6g / cm 3 , the average density ρ of all veneers is 0.473g / cm 3 , the standard deviation is 0.044g / cm 3 , figure 2 is the cumulative distribution function of the veneer density before veneer grading. figure 2 Among them, the ordinate represents CDF (cumulative distribution function); the abscissa represents the density of dry veneer in g / cm 3 .

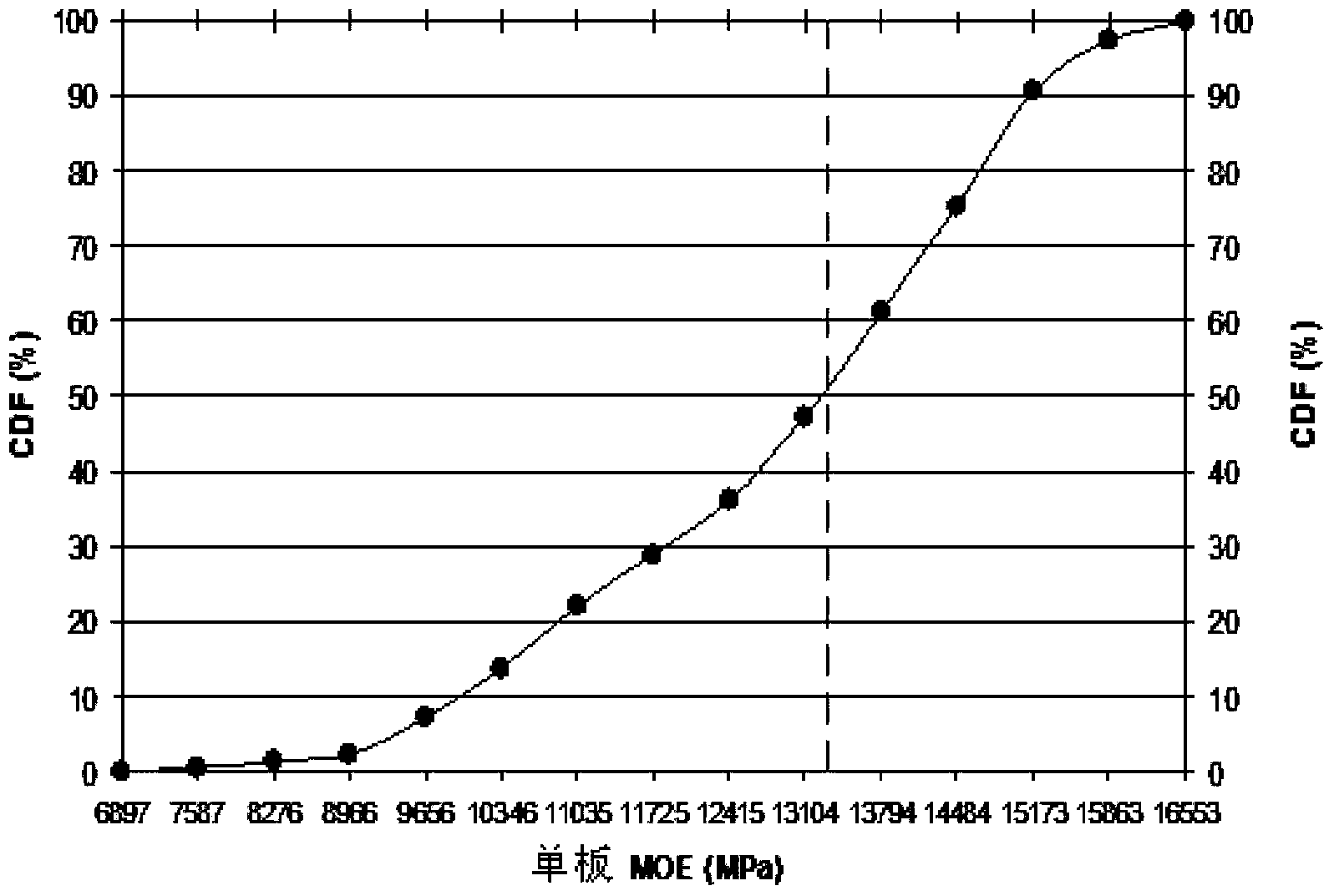

[0036] Measure the propagation time t of the stress wave in the length direction of the veneer according to the length of each veneer l veneer density ρ with MOE=ρv 2 Calculate the dynamic elastic modulus MOE of each veneer. The dynamic elastic modu...

Embodiment 2

[0044] Example 2: Production of laminated veneer boards (LVB) (veneer grading + impregnation of 2 veneers each on the surface layer and the bottom layer)

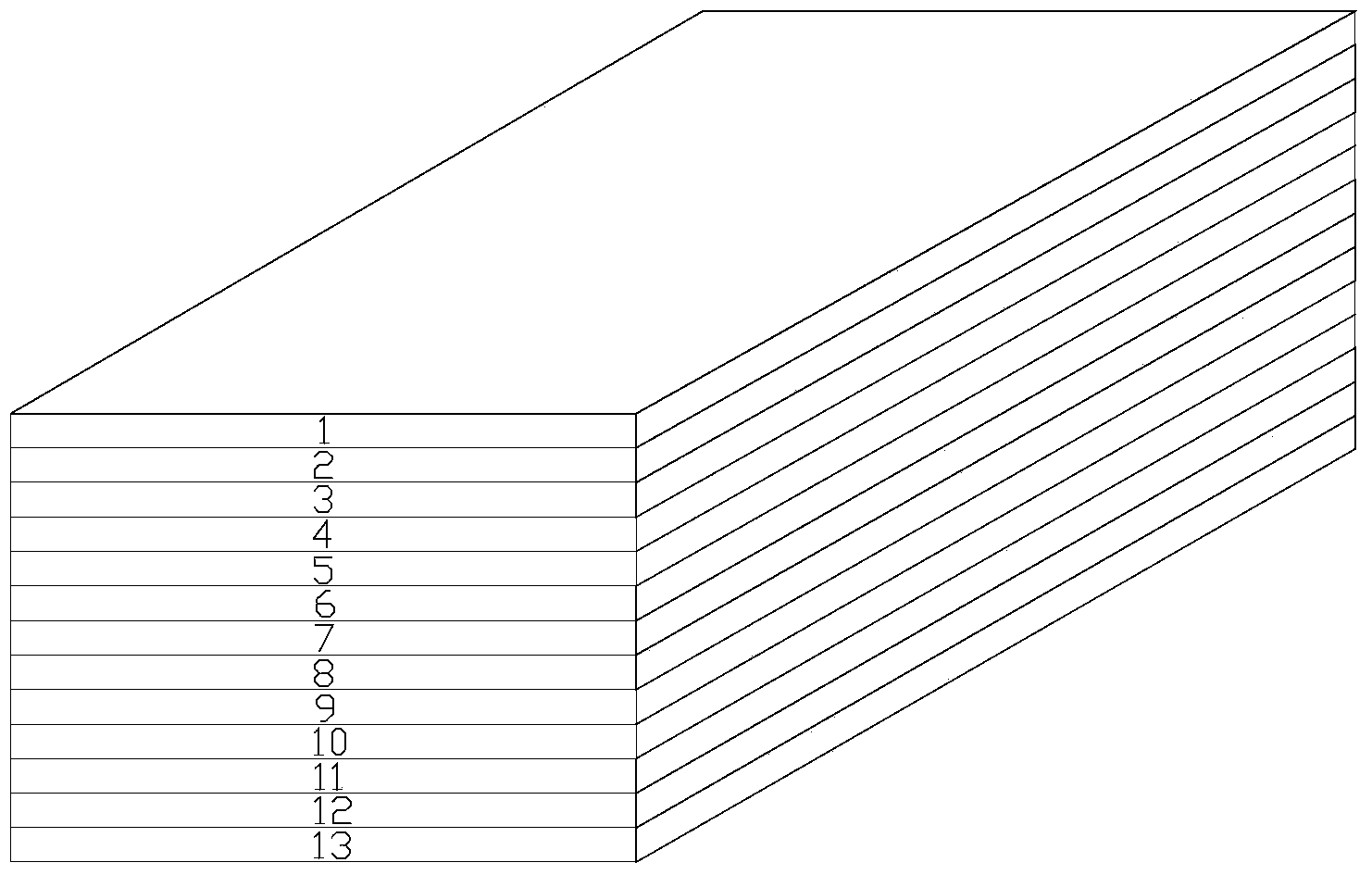

[0045] The difference between Example 2 and Example 1 is that the preform structure in Example 2 is a symmetrical structure, specifically, the surface layer and the bottom layer are respectively two layers of high-grade impregnated E1 veneers 1, 2, 12, and 13;

[0046] The two balance layers adjacent to the surface layer and the bottom layer are each a layer of high-grade impregnated E1 veneer 3, 11;

[0047] The core layer is 7 sheets of low-grade glue-coated E2 veneers 4-10; the grain direction of the balance layer is perpendicular to the grain direction of other veneers, see Figure 5 . Other processes are the same as in Example 1. The resulting laminated veneer boards were sawed and tested for their properties. The results are shown in Table 3.

Embodiment 3

[0048] Example 3: Production of laminated veneer boards (LVB) (veneer grading + impregnation of 1 veneer each for the surface layer and the bottom layer)

[0049] The difference between Example 3 and Example 1 is that the preform structure in Example 3 is a symmetrical structure, specifically, the surface layer and the bottom layer are respectively one layer of high-grade impregnated E1 veneer 1, 13;

[0050] The two balance layers adjacent to the surface layer and the bottom layer are each a layer of high-grade impregnated E1 veneer 2, 12; the core layer is 9 sheets of low-grade glue-coated E2 veneer 3-11; the grain direction of the balance layer is perpendicular to the grain of other veneers direction, see Figure 6 . Other processes are the same as in Example 1. The resulting laminated veneer boards were sawed and tested for their properties. The results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com