Constant-temperature high-voltage electrostatic spray device and method preparing polymer medicine-carrying nanoparticles by using same

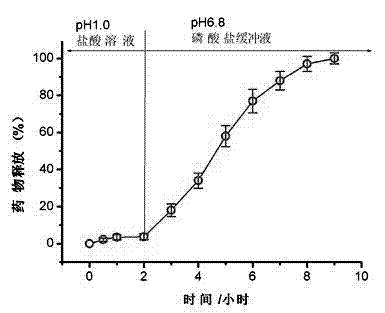

A technology of high-voltage electrostatic spraying and high-voltage power supply, which is applied in the direction of making medicines into special physical or ingestible devices, etc., which can solve the problems of complicated operation, difficult particle size regulation, cumbersome process, etc., and achieve simple preparation process and drug dispersion. The effect of good sex and satisfactory controlled release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A constant temperature and high pressure electrostatic spraying process device, specifically as figure 1 As shown, it includes an axial flow syringe pump 1, a high voltage power supply 3, a powder receiving plate 5, a syringe 2, a temperature regulator 4 and a syringe needle 6;

[0048] The high-voltage power supply 3 is connected to the syringe needle 6 of the syringe 2 through the crocodile pliers;

[0049] The high-voltage power supply 3 and the powder receiving plate 5 are commonly grounded;

[0050] The outer surface of the liquid storage tube 21 of the syringe 2 is wrapped with a flexible electric heating film 22, and the outer surface of the electric heating film is also wrapped with a heat insulating sleeve 23. The schematic diagram of its structure is as follows: figure 2 shown. The heat insulation cover 23 is an asbestos flame retardant material;

[0051] The flexible electric heating film 22 is regulated by the temperature regulator 4 to heat or stop heat...

Embodiment 2

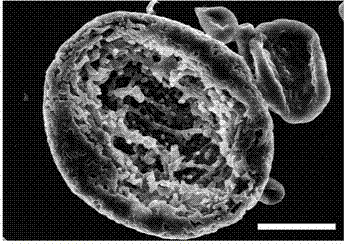

[0055]Utilizing the device described in Example 1, the method for preparing drug-loaded nanoparticles by electrostatic spraying of Eudragit L100 loaded with diclofenac sodium comprises the following steps:

[0056] (1) Preparation of eutectic electrospray solution

[0057] Dissolve 8.0g of Eudragit powder and 1.0g of diclofenac sodium in a mixed solvent of 100ml of methanol and DMAc, and stir magnetically for 1 hour to form a transparent eutectic electrospray solution;

[0058] The volume ratio of methanol to N,N-dimethylacetamide (DMAc) in the mixed solvent, that is, methanol: DMAc is 8:2;

[0059] (2) Control the eutectic electrospray solution obtained in step (1) at a temperature of 50°C for high-voltage electrostatic spraying, and finally obtain Eudragit L100 micro-nano particles loaded with diclofenac sodium;

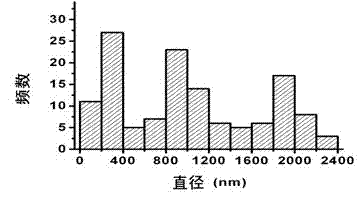

[0060] The high-pressure spray process controls the flow rate of the solution in the syringe to 2.0mL / h, the distance between the powder receiving plate and the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com