Carbon nanotube/ dendritic compound/ nanoparticle composite material and preparation method thereof

A carbon nanotube and nanoparticle technology is applied in the field of nanocomposite materials to achieve the effects of good stability, easy availability of raw materials and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

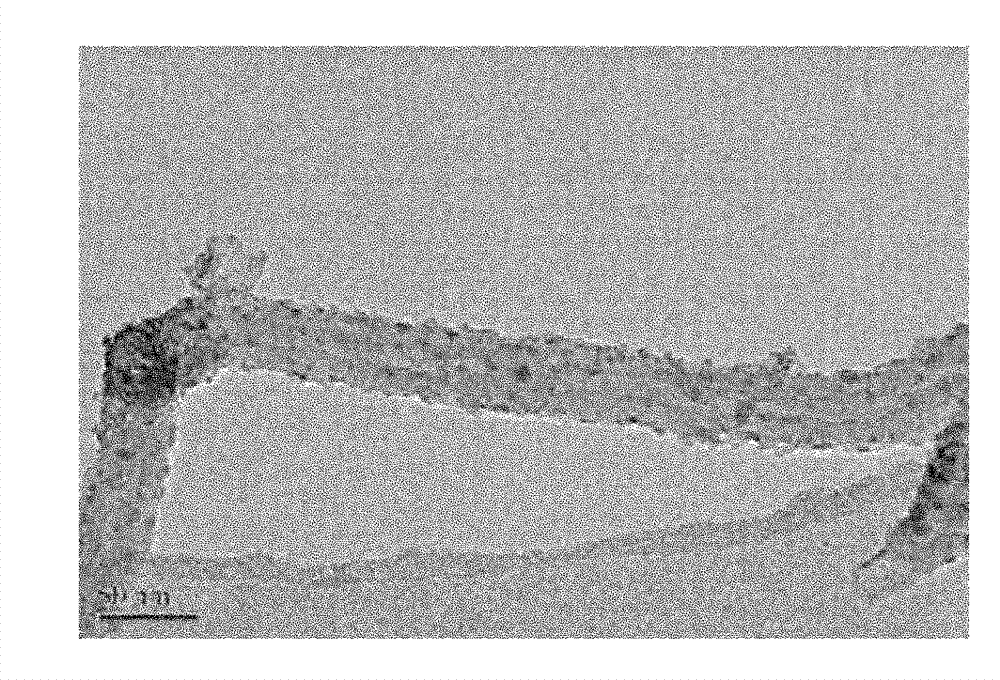

[0038] a) Prepare an aqueous solution of carbon nanotubes: place 5 mg of acid-treated multi-walled carbon nanotubes in 50 mL of distilled water, and ultrasonically disperse at 20° C. for 5 minutes;

[0039] b) At 20°C, add 3mL of 0.2g PAMAM methanol solution dropwise to the carbon nanotube aqueous solution prepared in step a), stir at room temperature for 2 hours, centrifuge to remove the supernatant, wash with methanol twice, and finally centrifuge The covalently modified carbon nanotubes of PAMAM were redispersed in 30mL of methanol;

[0040] c) At 20°C, add 10mL of 0.001mol / L methanol solution of copper acetate into the methanol solution of carbon nanotubes covalently modified with PAMAM prepared in step b), stir and react for 2 hours, press the formed metal sulfide Add 10mL of 0.001mol / L methanol solution of sodium sulfide dropwise to the stoichiometric ratio, then stir and react for 2 hours;

[0041] d) The supernatant was removed by centrifugation, and the centrifuged s...

Embodiment 2

[0048] a) Prepare an aqueous solution of carbon nanotubes: place 5 mg of acid-treated multi-walled carbon nanotubes in 50 mL of distilled water, and ultrasonically disperse at 25° C. for 5 minutes;

[0049] b) Ultrasonicate 3mL of 0.2g PAMAM methanol solution at 25°C for 2 hours, then add dropwise to the carbon nanotube aqueous solution prepared in step a), first stir at room temperature for 2 hours, centrifuge to remove the supernatant, wash with methanol twice , and finally redisperse the centrifuged covalently modified PAMAM carbon nanotubes in 30mL of methanol;

[0050] c) At 25°C, add 0.0005 mol / L silver nitrate methanol solution into the carbon nanotube methanol solution covalently modified with PAMAM prepared in step b), stir and react for 2 hours, according to the chemical composition of the formed metal sulfide Add 10mL of 0.001mol / L methanol solution of sodium sulfide drop by drop, and then stir for 2 hours;

[0051] d) The supernatant was removed by centrifugation,...

Embodiment 3

[0056] a) Prepare an aqueous solution of carbon nanotubes: place 5 mg of acid-treated multi-walled carbon nanotubes in 50 mL of distilled water, and ultrasonically disperse at 20° C. for 5 minutes;

[0057] b) At 20°C, add 3mL of 0.2g PAMAM methanol solution dropwise to the carbon nanotube aqueous solution prepared in step a), first stir at room temperature for 2 hours, centrifuge to remove the supernatant, wash with methanol twice, and finally centrifuge The final covalently modified PAMAM carbon nanotubes were redispersed in 30mL methanol;

[0058] c) At 20°C, add 0.0005mol / L methanol solution of metal silver nitrate to the methanol solution of carbon nanotubes covalently modified with PAMAM prepared in step b), stir and react for 2 hours, then add 20mL of 0.1mol / L dropwise Sodium borohydride methanol solution, the metal silver ion in the solution is reduced to elemental silver;

[0059] d) The supernatant was removed by centrifugation, and the centrifuged solid was washed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com