Degradation method for halogenated disinfection by-products

A technology of disinfection by-products and dissolved oxygen concentration, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve inconvenience, high operating costs, secondary pollution, etc. problems, to achieve the effect of convenient use and management, guarantee of water quality safety, and rapid removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

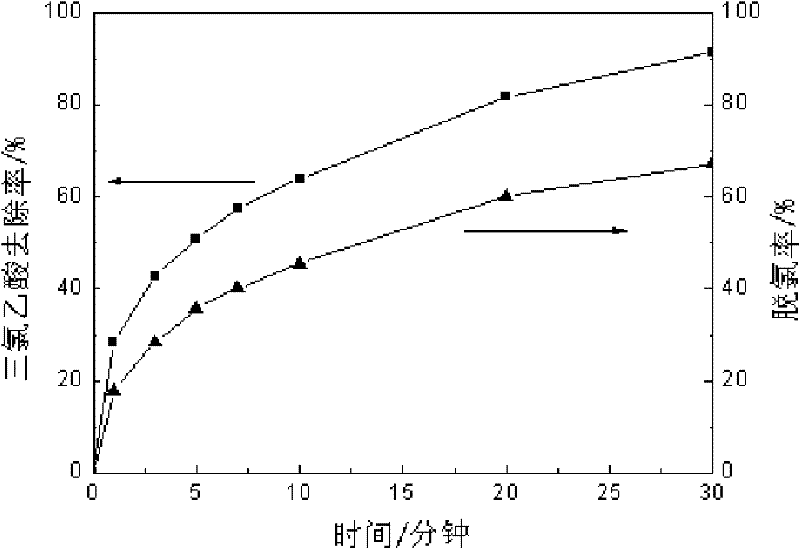

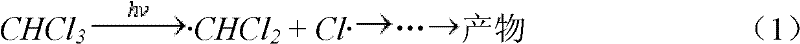

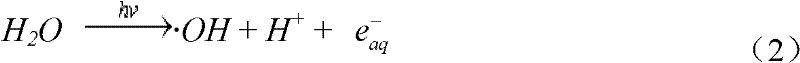

[0028] Specific Embodiment 1: This embodiment is a method for degrading halogenated disinfection by-products, which is achieved through the following steps: adjusting the pH value of the water body to above 7, controlling the dissolved oxygen concentration in the water body to be lower than 2 mg / L, and then using The ultraviolet light with a wavelength of 150-260nm is irradiated to complete the degradation of halogenated disinfection by-products.

[0029]The degradation method of halogenated disinfection by-products in this embodiment does not require expensive oxidants and catalysts, does not produce secondary pollution, does not require follow-up treatment, and does not significantly change the taste of water quality; it can quickly remove disinfection by-products and is convenient Reactors are designed to meet the needs of various water bodies, easy to use and manage, and can ensure water quality safety. It is a safe, efficient, broad-spectrum and economical degradation met...

specific Embodiment approach 2

[0031] Embodiment 2: This embodiment differs from Embodiment 1 in that the concentration of dissolved oxygen in the water body is controlled to be lower than 1 mg / L. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0032] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the irradiation time of ultraviolet light is controlled to be 0.1-100 minutes, and the dose of ultraviolet light is 15-90000 joules / liter. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

[0033] The specific ultraviolet light irradiation time or ultraviolet light dose of the present invention can be comprehensively determined according to actual water quality characteristics (pollutant concentration, turbidity, chromaticity) and light source characteristics (irradiation light intensity, illumination depth), etc., according to the existing The design specifications and requirements can easily determine the specific ultraviolet light irradiation time and dosage corresponding to different water qualities within the above range of ultraviolet light irradiation time and dose.

[0034] For the treatment of conventional drinking water, the UV dose can generally be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com