Foamed plastic sheet material prepared from waste and old polypropylene and rubber, and preparation method thereof

A technology of waste polypropylene and foam plastics, which is applied in the field of engineering plastics, can solve problems such as waste and environmental pollution, and achieve the effects of no three wastes discharge, improved melt strength, and simple operation techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

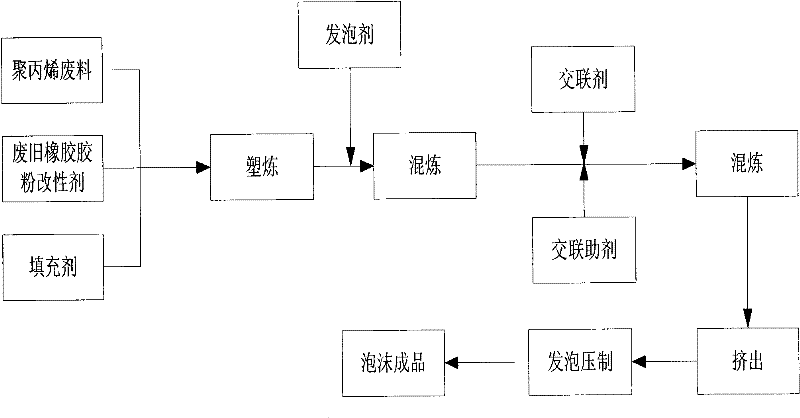

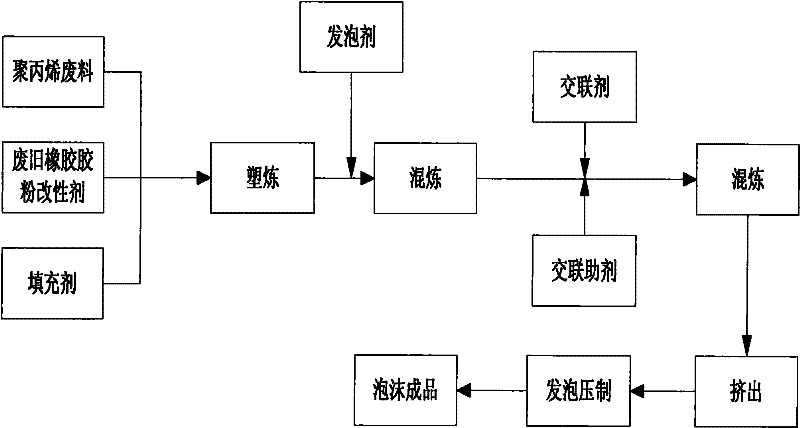

Method used

Image

Examples

Embodiment 1

[0033] 80 parts of waste polypropylene film, 15 parts of modifier waste rubber powder, 4 parts of dicyandiamide AC foaming agent, 0.5 part of cross-linking agent dicumyl peroxide, 40 parts of filler talcum powder, cross-linking auxiliary agent 0.5 parts of divinylbenzene.

[0034] Add waste polypropylene film, modifier and filler plastics to the mixer according to the metering, knead for 10 minutes at 110°C, then add dicyandiamide AC foaming agent, and mix at 80°C for 10 minutes minutes; continue to add cross-linking agent dicumyl peroxide and cross-linking aid divinylbenzene, knead at 80°C for 10 minutes, and cross-link molding; put the mixture into the extruder and extrude, Foaming and shaping in the plastic machine, the foaming temperature is 160°C, and the heating time is 15 minutes to obtain a foamed plastic sheet product 1, microporous, density 0.18g / cm3, Shore hardness 36, tensile strength 0.95Mpa, elongation Elongation 86%, elasticity 27%.

Embodiment 2

[0036] 90 parts of waste polypropylene film, 30 parts of modifier waste rubber powder, 7 parts of dicyandiamide AC foaming agent, 1.0 parts of cross-linking agent dicumyl peroxide, 80 parts of filler talcum powder, cross-linking auxiliary agent 0.8 parts of divinylbenzene.

[0037] Add waste polypropylene film, modifier and filler plastics to the mixer according to the metering, knead at 120°C for 5 minutes, then add dicyandiamide AC foaming agent, knead at 100°C and 7 minutes; continue to add the cross-linking agent dicumyl peroxide and the cross-linking auxiliary divinylbenzene, knead and knead for 7 minutes at 100 ° C, cross-linking; put the mixture into the extruder to extrude, Foaming and shaping in a hot compression molding machine, the foaming temperature is 170°C, and the heating time is 13 minutes to obtain a foamed plastic sheet product 2, microporous, density 0.22g / cm3, Shore hardness 38, tensile strength 0.98Mpa, 87% elongation, 29% elasticity.

Embodiment 3

[0039] 100 parts of waste polypropylene film, 40 parts of modifier waste rubber powder, 10 parts of dicyandiamide AC foaming agent, 1.5 parts of cross-linking agent dicumyl peroxide, 110 parts of filler talcum powder, cross-linking auxiliary agent 1 part of divinylbenzene.

[0040] Add waste polypropylene film, modifier and filler plastic in the mixer according to the metering, knead at 120°C for 5 minutes, then add dicyandiamide AC foaming agent, knead at 120°C and 5 minutes; continue to add crosslinking agent dicumyl peroxide and crosslinking aid divinylbenzene, knead and knead for 5 minutes at 120 ° C, crosslinking; put the mixture into the extruder to extrude, Foaming and shaping in a hot compression molding machine, the foaming temperature is 180°C, and the heating time is 10 minutes to obtain a foamed plastic sheet product 3, microporous, density 0.28g / cm3, Shore hardness 40, tensile strength 1.00Mpa, 88% elongation, 30% elasticity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com