Preparation method of p-CuAlO2/n-ZnO:Al transparent thin film heterojunction of glass substrate

A p-cualo2, glass substrate technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems that the performance cannot meet the application requirements, the process is complicated, and the equipment is expensive, and achieves good light transmittance in the visible light region. , precise control, high uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

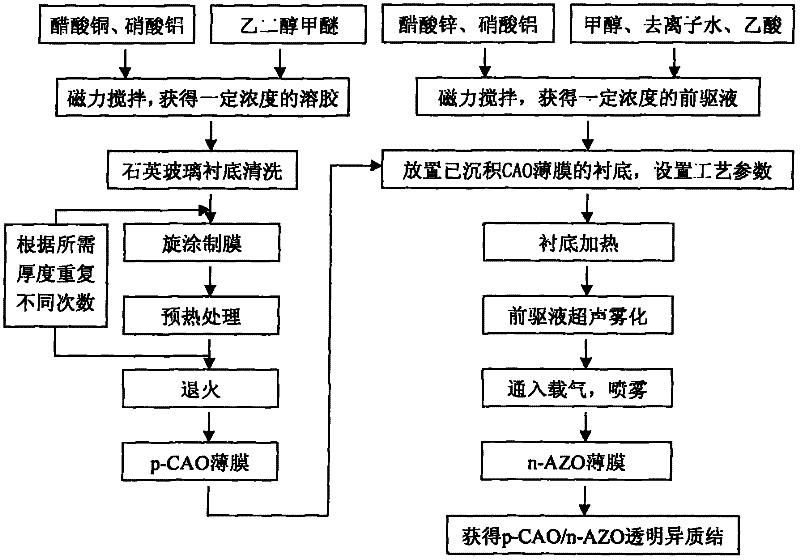

[0055] A glass substrate p-CuAlO 2 / n-ZnO: the preparation method of Al transparent film heterojunction, comprises the steps:

[0056] (1) Using quartz glass as the substrate, the substrate is subjected to surface treatment and cleaning; the process steps of surface treatment and cleaning are:

[0057] ①Soak in sodium hydroxide solution for 24 hours to remove the remaining attachments on the surface;

[0058] ② Ultrasonic cleaning with acetone for 10-15 minutes to remove organic matter on the substrate surface;

[0059] ③Ethanol supershock for 8-10 minutes to remove hydrocarbons on the glass surface;

[0060] ④Finally, supershock with deionized water for 10 minutes to remove residual ethanol;

[0061] (2) Preparation of CAO sol: the raw materials whose purity is 99.99% of analytical purity are used:

[0062] Aluminum nitrate (Al(NO 3 ) 3 9H 2 O) 102.04 grams

[0063] Copper acetate (Cu(CH 3 COO) 2 ·H 2 O) 77.66 grams

Embodiment 2

[0092]Carry out according to the method step of embodiment 1, difference is:

[0093] (2) The following raw materials (whose purity is 99.99% of analytical purity) are used to prepare CAO sol:

[0094] Aluminum nitrate (Al(NO 3 ) 3 9H 2 O) 116.67 grams

[0095] Copper acetate (Cu(CH 3 COO) 2 ·H 2 O) 77.66 grams

[0096] Ethylene glycol methyl ether (CH 3 OCH 2 CH 2 OH) 1000ml

[0097] Wherein: (a) the mol ratio of solute aluminum nitrate and copper acetate is 0.80: 1.00; (b) 0.700 mole of solute (which contains: 0.311 mole of aluminum nitrate, 0.389 mole of copper acetate) is mixed with 1000 milliliters of ethylene glycol methyl ether solvent.

[0098] (4) The wet film of the glue is dried at a low temperature at 100°C to remove the carbon and hydrogen components in the wet film;

[0099] (5) Preheating the dried film on a constant temperature hot plate at 350°C;

[0100] (6) Repeat the above steps (3)-(5) eight times to obtain a CAO film with a thickness of about...

Embodiment 3

[0109] Carry out according to the method step of embodiment 1, difference is:

[0110] (2) The following raw materials (whose purity is 99.99% of analytical purity) are used to prepare CAO sol:

[0111] Aluminum nitrate (Al(NO 3 ) 3 9H 2 O) 131.30 grams

[0112] Copper acetate (Cu(CH 3 COO) 2 ·H 2 O) 77.66 grams

[0113] Ethylene glycol methyl ether (CH 3 OCH 2 CH 2 OH) 1000ml

[0114] Wherein: (a) the mol ratio of aluminum nitrate and copper acetate is 0.90: 1.00; (b) 0.740 mole solute (wherein contains: aluminum nitrate 0.350 mole, copper acetate 0.389 mole) mixes 1000 milliliters of ethylene glycol methyl ether solvents.

[0115] (4) The wet film of the glue is dried at a low temperature at 120°C to remove the carbon and hydrogen components in the wet film;

[0116] (5) Preheating the dried film on a constant temperature hot plate at 370°C;

[0117] (6) Repeat the above steps (3)-(5) seven times to obtain a CAO film with a thickness of about 280nm;

[0118] (7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com