High-concentration multi-junction solar cell and preparation method thereof

A technology for solar cells and high concentration of light, which is applied in photovoltaic power generation, circuits, electrical components, etc., and can solve problems such as large open circuit voltage and short circuit current, reduced battery conversion efficiency, and affecting battery fill factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

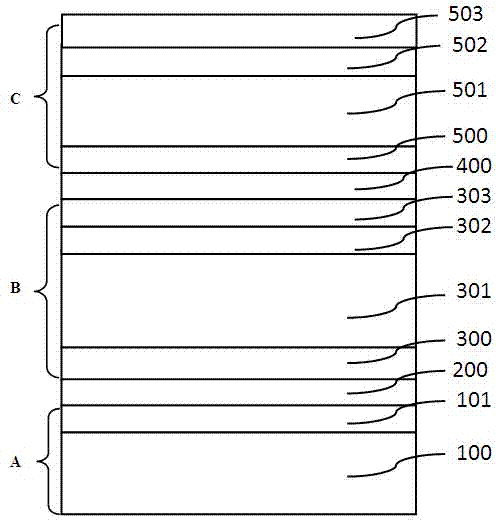

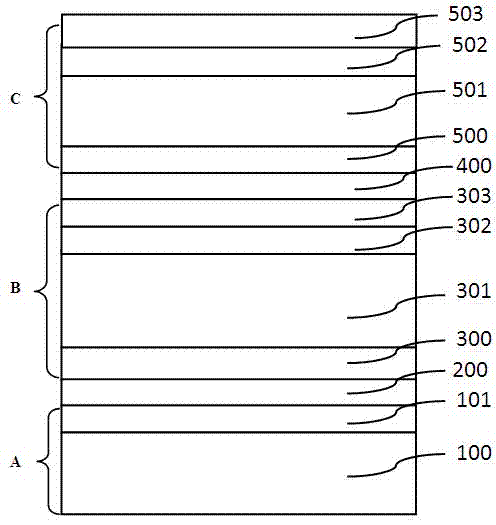

[0037] Such as figure 1 As shown, a high concentration multi-junction solar cell includes a Ge bottom cell A, a middle cell B, a top cell C and two tunnel junctions 200 and 400 therebetween.

[0038] More specifically, the figure shows: a p-type Ge substrate 100 on which an n-type Ga 0.5 In 0.5 The P window layer 101 constitutes the Ge bottom cell A.

[0039] A series of heavily doped p-type and n-type layers are deposited on top of the Ge bottom cell A to form a GaAs tunnel junction 200 for connecting the Ge bottom cell A to the middle cell B.

[0040] A mid-cell back field layer 300 for reducing recombination loss is deposited on top of the GaAs tunneling junction 200, and this layer is preferably made of p-type AlGaAs.

[0041] On the back field layer 300 of the middle cell, a base region 301 of the middle cell and an emitter layer 302 of the middle cell are deposited. In this preferred example, the base region 301 of the middle cell is made of p-type (In) GaAs, and its...

Embodiment 2

[0046] This embodiment is a preparation process of a high-power concentrating multi-junction solar cell described in Example 1, which includes the formation process of sub-cells A, B, C and layers between the sub-cells. In the MOCVD epitaxial growth process, the doping concentration of the emission layer can be gradually changed by adjusting the flow ratio of the n-type doping source in the reaction source.

[0047] Concrete preparation process comprises the following steps:

[0048] A p-type doped single crystal germanium substrate 100 with a thickness of 150 microns is used as the base region of the Ge bottom cell.

[0049] Clean the p-type Ge substrate 100 and put it into the MOCVD reaction chamber, first bake it at 750°C for 10 minutes, then lower the temperature to 600°C, and epitaxially grow n-type Ga 0.5 In 0.5 The P window layer 101 forms a Ge bottom cell A.

[0050] The GaAs tunneling junction 200 of the mid-bottom cell is epitaxially grown on the Ge bottom cell. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com