Etoposide long-circulating emulsion and preparation method thereof

A technology of long-term poside and emulsion, applied in the field of etoposide long-circulating emulsion and its preparation, can solve problems such as difficulty in drug loading, and achieve the effects of avoiding drug degradation, increasing concentration and reducing toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

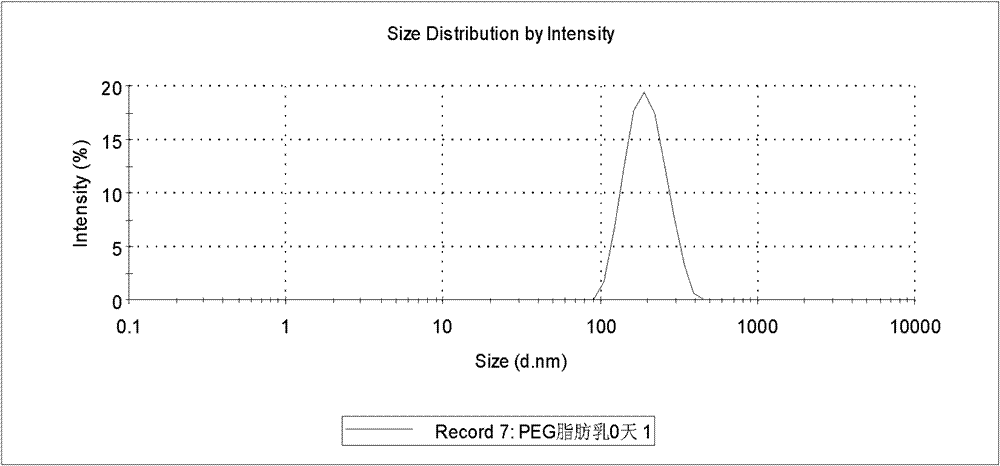

[0046] Add 1.0 g of lecithin, 0.02 g of PEG-DSPE, 0.05 g of oleic acid, and 0.01 g of etoposide into 10 g of soybean oil, and heat in an ultrasonic water bath (40° C.) to dissolve to obtain an oil phase. Take 2.25g of glycerin and dissolve it in 70ml of water for injection as the water phase. In a water bath at 50°C, add the oil phase to the water phase, stir while adding, and cut at 15,000rpm for 20min to obtain colostrum, adjust the pH to about 4.5-5, and make up the injection Water to 100ml, in a microfluidizer, the pressure 80MPa milk evenly 5 times, filling, nitrogen gas, melting seal, 121 ℃ rotary autoclaving for 10 minutes to obtain the final milk.

[0047] Average particle size = 193.7nm, PI = 0.092, encapsulation efficiency = 95.8%

Embodiment 2

[0049] Take 1.2 g of soybean lecithin, 0.1 g of PEG-DSPE, 0.10 g of oleic acid, and 0.05 g of etoposide, add them to 20 g of soybean oil, and heat them in an ultrasonic water bath (50° C.) to dissolve to obtain an oil phase. Take 2.25g of glycerin and dissolve it in 70ml of water for injection as the water phase. In a water bath at 60°C, add the oil phase to the water phase, stir while adding, and cut at 15,000 rpm for 20 minutes to obtain colostrum. Adjust the pH to about 4.5-5, and make up the injection Water to 100ml, in a microfluidizer, the pressure 80MPa milk evenly 5 times, filling, nitrogen gas, melting seal, 121 ℃ rotary autoclaving for 10 minutes to obtain the final milk.

[0050] Average particle size = 196.9nm, PI = 0.052, encapsulation efficiency = 96.7%

Embodiment 3

[0052] Get soybean oil and MCT, prepare mixed liquid oil 20g according to 1:1, get soybean lecithin 1.4g, PEG-DSPE0.4g, oleic acid 0.05g, etoposide 0.1g join in above-mentioned mixed oil phase, ultrasonic water bath heating ( 50°C) to obtain an oily phase. Take 2.25g of glycerin and dissolve it in 70ml of water for injection as the water phase. In a water bath at 70°C, add the oil phase to the water phase, stir while adding, and cut at 15,000rpm for 20min to obtain colostrum, adjust the pH to about 4.5-5, and make up the injection Water to 100ml, in a microfluidizer, the pressure 80MPa milk evenly 5 times, filling, nitrogen gas, melting seal, 121 ℃ rotary autoclaving for 10 minutes to obtain the final milk.

[0053] Average particle size = 191.7nm, PI = 0.082, encapsulation efficiency = 97.8%

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com