Clean nitration reaction of p-chlorobenzotrifluoride under catalysis of degradable functional ionic liquid

A technology of p-chlorotrifluorotoluene and ionic liquid, applied in physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, organic chemistry, etc., can solve the difficulty of increasing post-processing, product separation, imidazole ionic liquids are expensive, cannot meet environmental and economic problems, and achieve the effects of good industrial application prospects, environmental friendliness, and convenient preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

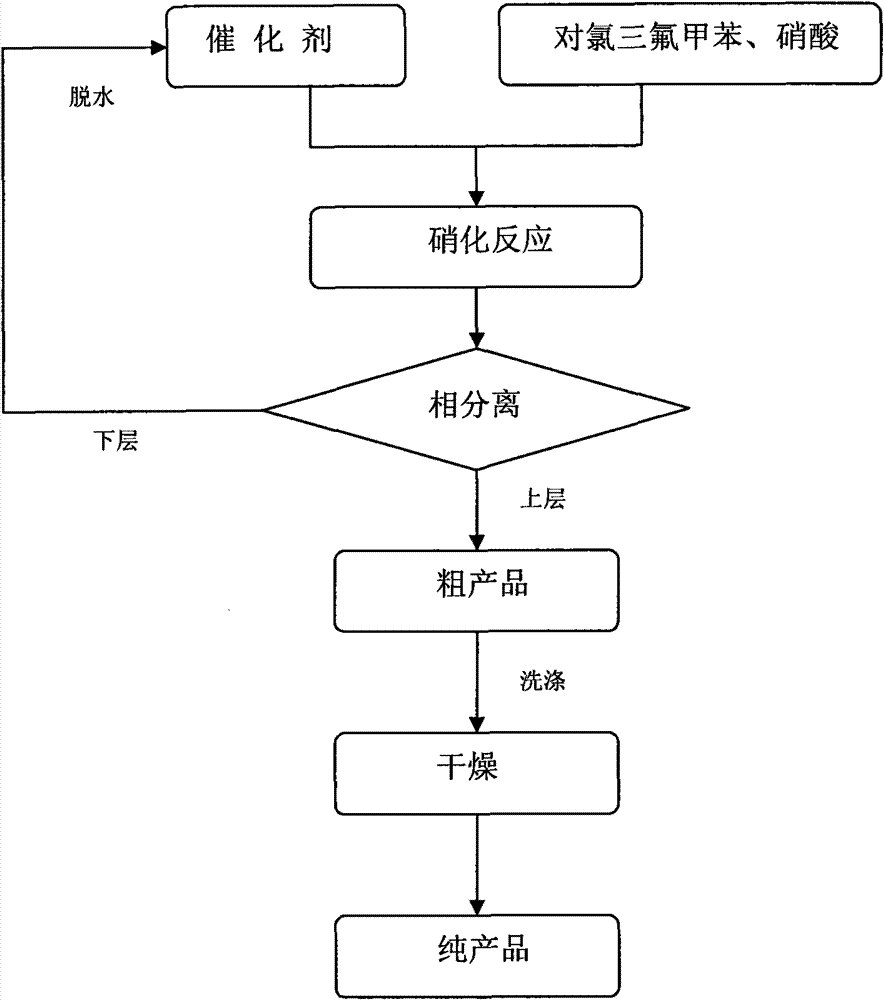

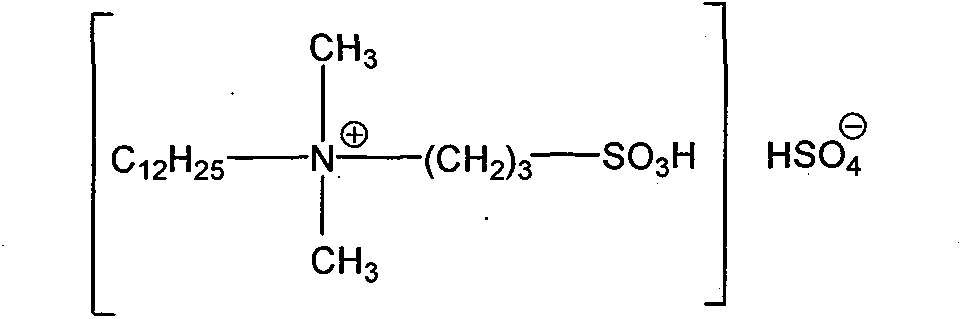

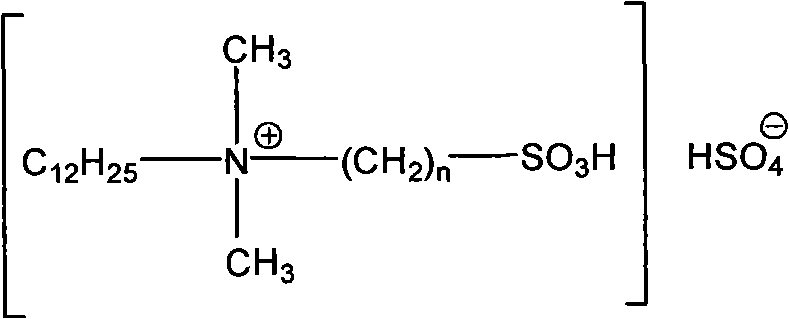

[0022] In a 25mL round bottom flask, add 10mmol (1.81g) of p-chlorobenzotrifluoride, 30mmol (2.8g) of 68% nitric acid, and 1.5mmol (0.65g) of catalyst in sequence, mix and stir for 10 hours at 100°C, cool, and statically The phases were separated, the crude product in the upper layer was washed with water, neutralized and dried in vacuum to obtain the pure product 4-chloro-3-nitrobenzotrifluoride with a yield of 80%.

Embodiment 2

[0024] In a 25mL round bottom flask, add 10mmol (1.81g) of p-chlorobenzotrifluoride, 10mmol (0.63g) of 100% nitric acid, and 1mmol (0.43g) of catalyst in turn, mix and stir at 30°C for 8 hours, cool and stand The phases were separated, the crude product in the upper layer was washed with water, neutralized and dried in vacuum to obtain the pure product 4-chloro-3-nitrobenzotrifluoride with a yield of 81%.

Embodiment 3

[0026] In a 25mL round bottom flask, add 10mmol (1.81g) of p-chlorobenzotrifluoride, 20mmol (1.4g) of 90% nitric acid, and 0.5mmol (0.22g) of catalyst in turn, mix and stir for 5 hours at 80°C, cool and statically The phases were separated, the crude product in the upper layer was washed with water, neutralized and dried in vacuum to obtain the pure product 4-chloro-3-nitrobenzotrifluoride with a yield of 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com