Steel belt for bimetal saw back and production technique thereof

A production process, bimetal technology, applied in the field of saw back steel strip and its production process, can solve the problem of no improvement in material and production process, poor performance of the saw back material of bimetal saws, high performance bimetal saws Problems such as high production costs, to achieve the effects of strong operability of the production process, conducive to market promotion and application, and important strategic significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

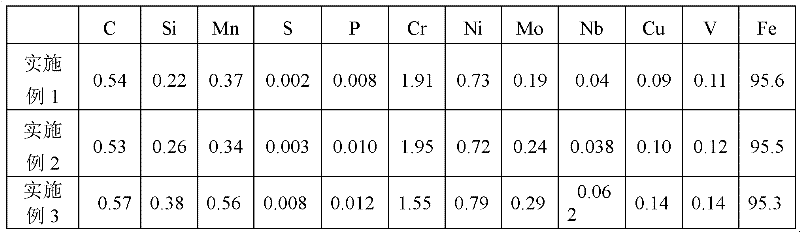

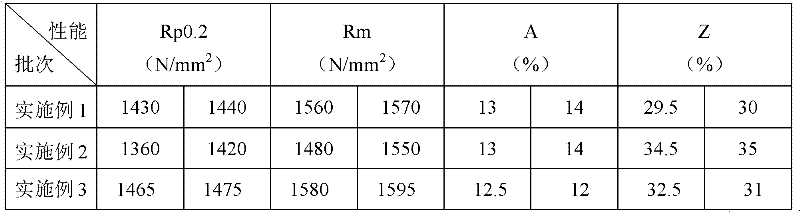

Embodiment 1

[0079] The basic flow of the production process: EAF primary refining→LF refining→VD refining→continuous casting→rolling.

[0080] The following percentages are all in mass percent:

[0081] (1) EAF primary refinement:

[0082] The raw material adopts 40% molten iron and 60% scrap steel, and the raw material is 100 tons in total. The mass percentage content of As in the molten iron is 0.0080%. Add high-chromium iron (FeCr65C9.5, including 9.5% carbon, 65% chromium, Less than 5% other impurities and the balance is iron) 10Kg / ton raw material and medium ferrochromium (FeCr65C3.0, including 3.0% carbon, 65% chromium, less than 5% other impurities and the balance is iron) 18Kg / 1 ton of raw material, pure nickel plate 7.4Kg / ton of raw material, add quicklime, the amount of quicklime added is 55Kg / ton of raw material, initial smelting in the EAF primary smelting furnace at 1550 ° C ~ 1680 ° C for 50 minutes, put steel after the initial smelting, put steel The temperature is 1660°...

Embodiment 2

[0092] The basic flow of the production process: EAF primary refining→LF refining→VD refining→continuous casting→rolling.

[0093] The following percentages are all in mass percent:

[0094] (1) EAF primary refinement:

[0095] In terms of mass percentage, the raw material adopts 40% molten iron and 60% steel scrap, and the raw material is 100 tons in total. The mass percentage content of As in the molten iron is 0.0100%. Add high-chromium iron (FeCr65C9.5, including 9.5% carbon, 65% chromium, less than 5% other impurities and the balance is iron) 12Kg / ton raw material and medium chromium iron (FeCr65C3.0, including 3.0% carbon, 65% chromium, less than 5% other impurities and the balance Iron) 17Kg / ton raw material; pure nickel plate 7.3Kg / ton raw material, add quicklime, the amount of quicklime added is 54Kg / ton raw material, initial smelting in EAF primary smelting furnace at 1550℃~1680℃ for 52min, put Steel, the temperature of putting steel is 1648 ℃, obtains the molten s...

Embodiment 3

[0105] Basic process of production process: EAF primary refining→LF refining→VD refining→continuous casting→rolling

[0106] The following percentages are all in mass percent:

[0107] (1) EAF primary refinement:

[0108] In terms of mass percentage, the raw material adopts 35% pig iron block and 65% scrap steel, the raw material is 100 tons in total, the mass percentage content of As in molten iron is 0.0090%, and high chromium iron (FeCr65C9.5, including 9.5% carbon , 65% chromium, less than 5% other impurities and the balance is iron) 14Kg / ton of raw materials and medium ferrochromium (FeCr65C3.0, including 3.0% carbon, 65% chromium, less than 5% other impurities and balance The amount is iron) 10Kg / ton of raw materials; pure nickel plate 7.8Kg / ton of raw materials, add quicklime, the amount of quicklime added is 48Kg / ton of raw materials, in the EAF primary smelting furnace at 1550 ° C ~ 1680 ° C for 43 minutes, after the initial smelting Putting steel, the temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com