304 stainless steel bipolar plate for SnO2 film modified proton exchange membrane fuel cell (PEMFC) and preparation method of 304 stainless steel bipolar plate

A 304 stainless steel, bipolar plate technology, applied in solid-state chemical plating, metal material coating technology, coating and other directions, can solve the problems of difficult to widely use, practical limitations, complex methods, etc., to achieve good corrosion resistance and Stability, avoid battery life impairment, good mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

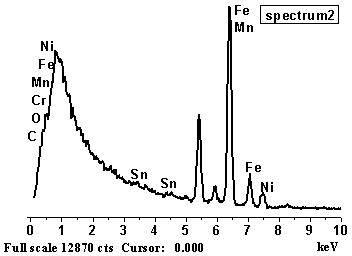

[0041] A kind of SnO 2 The preparation method of 304 stainless steel bipolar plates for membrane modified PEMFC comprises the steps:

[0042] (1), 3.2gSnCl 2 2H 2 O, 0.23g polyethylene glycol 2000, 50ml absolute ethanol, electromagnetically stirred at 50°C for 2h, cooled naturally, and aged for 24h to obtain a colorless transparent sol;

[0043] (2) Pre-treat the 304 stainless steel substrate material 10mm×70mm×2mm, that is, use metallographic sandpaper (#2~#6) to polish it step by step, and degrease the polished substrate 304 stainless steel with absolute ethanol, And use ultrasonic cleaning for 5min, then wash with deionized water, and finally dry with air for use;

[0044] (3) Take 10ml of the sol from step (1) and put it into a 10ml small beaker, and then dip-pull the 304 stainless steel treated in step (2) to form a film. The dipping time is 20s, and the pulling speed is 2mm / s. The number of pulls is 2 times. After the pull is completed, the film is dried naturally an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com