Method for detecting chloride ions in polyisobutylene

A technology of polyisobutylene and detection method, which is applied in the direction of electrochemical variables of materials, etc., can solve the problems of inability to directly dissolve or extract with water, and achieve the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

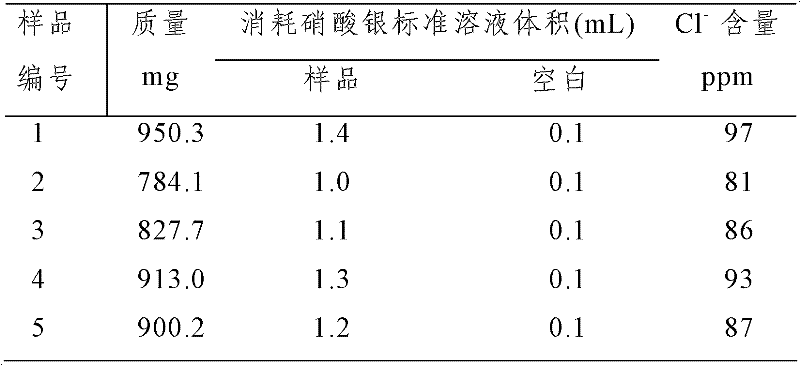

Embodiment 1

[0043] Take 5.0g polyisobutylene sample (HRD-350), after quenching with liquid nitrogen, the sample temperature is -120~-170°C, quickly grind it in a mortar until the particle size is ≤200μm, divide the sample into five parts, and weigh the sample accurately If the weight error is ≤0.1mg, put the sample into the platinum basket combustion chamber, put it into the oxygen combustion bottle with 10.0mL water added in advance, tighten the screw cap of the oxygen combustion bottle, connect the oxygen cylinder, and pass oxygen at a flow rate of 3.0L / min for 2min. When the oxygen combustion bottle is filled with oxygen (the oxygen pressure generated should be lower than the safety pressure specified by the manufacturer), quickly disconnect the oxygen system. Put the oxygen combustion bottle containing the sample into the combustion device, close the door of the combustion device, press the "START" switch, the light source will continue to work for 10 seconds, ignite the sample and bur...

Embodiment 2

[0050] Take 5.0 g of polyisobutylene sample (HRD-550), the operation steps are the same as in Example 1, the particle size of the pretreated sample is less than 200 μm, and the measurement results are shown in Table 2.

[0051]Table 2. HRD-550 sample chloride ion determination results, sample particle size ≤ 200μm.

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com