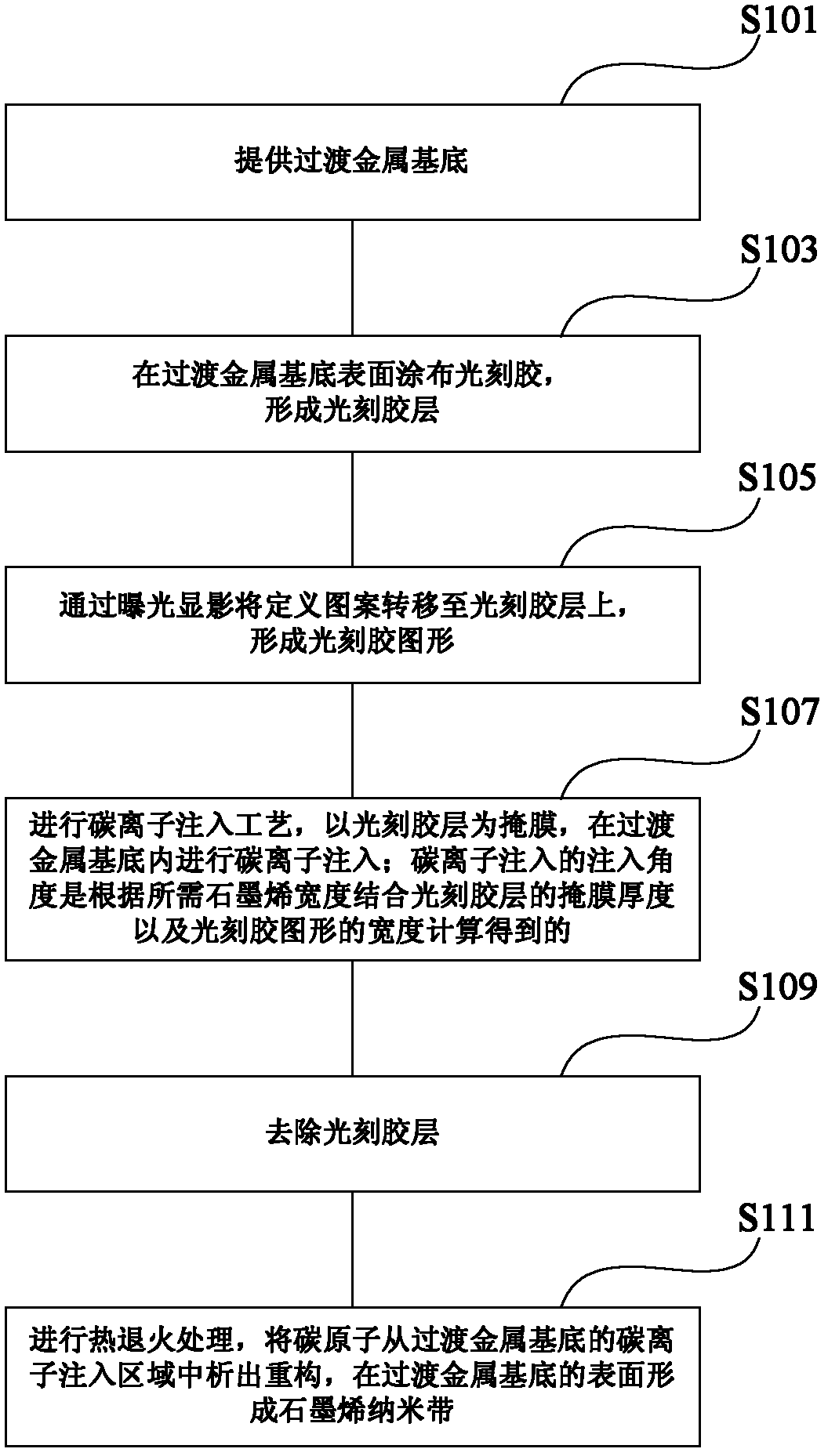

Preparation method of one-dimensional scale limited graphene nano band

A graphene nanoribbon and scale technology, applied in nanotechnology, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of complex preparation and difficult width control, and achieve precise preparation, high yield and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In the preparation technology of graphene nanobelts, the inventors of the present invention have improved the prior art and proposed a novel preparation method of one-dimensional scale-limited graphene nanoribbons, which mainly utilizes The surface of the metal substrate uses photoresist as an implantation mask, and implants carbon ions into a specific region of the transition metal substrate at a calculated optimal implantation angle, and uses thermal annealing to precipitate and reconstruct carbon atoms, so that the transition metal One-dimensional scale-limited graphene nanoribbons with a width close to or even less than 10 nm are formed on the surface of the substrate.

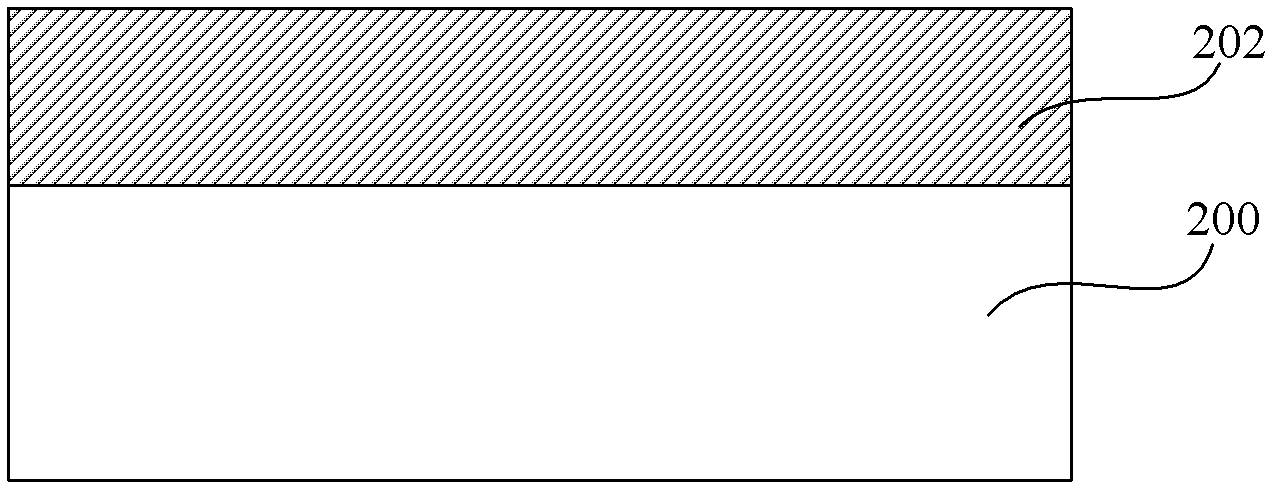

[0018] The invention is described more fully below with reference to the drawings, which provide preferred embodiments, but should not be considered limited to the embodiments set forth herein. In the figure, the thicknesses of layers and regions are appropriately enlarged for a clearer reaction str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com