Circularly polarized waveguide flat plate array antenna

An array antenna and circularly polarized wave technology, which is applied in the field of circularly polarized waveguide plate array antennas, can solve the problems of being unable to manufacture low-cost, high-efficiency satellite live TV receiving antennas, and is difficult to produce in large quantities, so as to achieve low production costs , Improve efficiency, high gain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

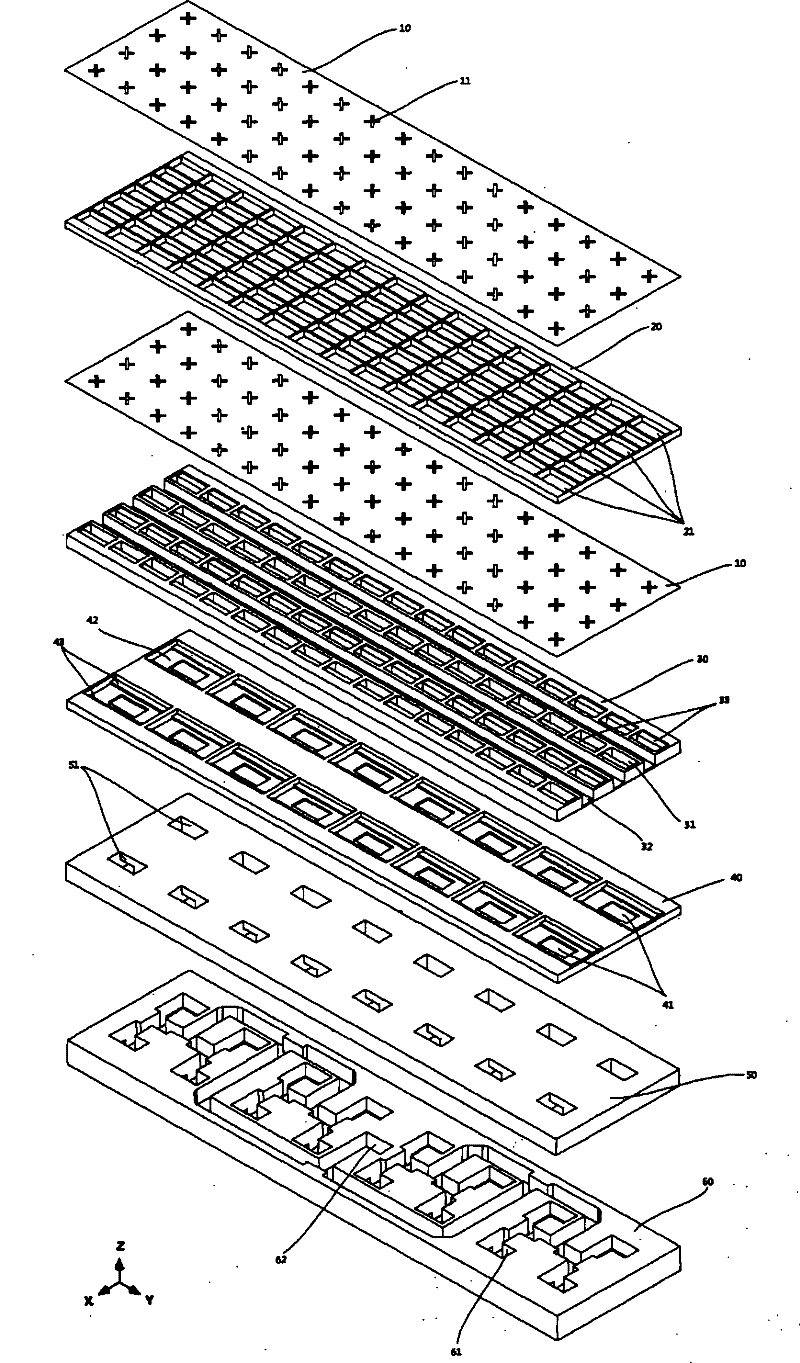

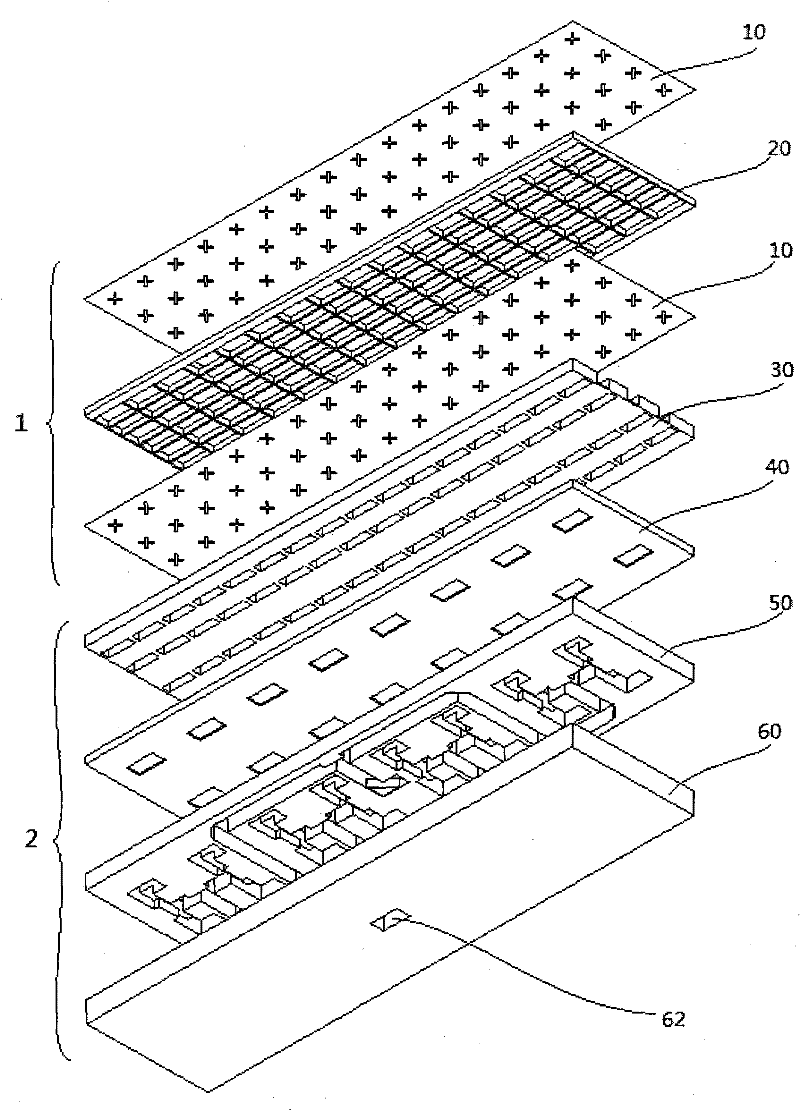

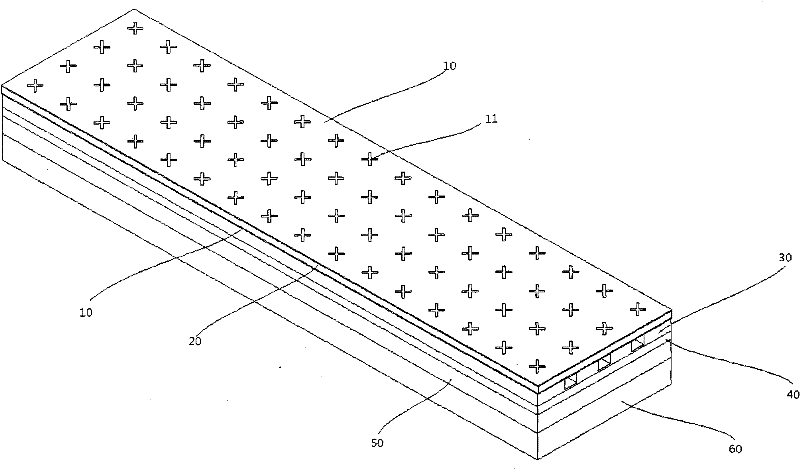

[0021] Such as figure 1 , 2 The antenna shown is composed of seven layers, which are dielectric film 10, dielectric frame 20, dielectric film 10, radiation layer 30, rectangular excitation cavity layer 40, waveguide E-T feed network upper layer 50, waveguide E-T feed network Lower level 60. The first three layers form a circular polarizer 1, and the last four layers form a waveguide plate array antenna 2. The circular polarizer 1 is stacked on the waveguide plate array antenna 2 to form a circularly polarized waveguide plate array antenna, which is located in the lower layer of the waveguide E-T feed network The input and output waveguide port 62 in the middle of 60 is the final input and output port of the signal. image 3 , 4 A circularly polarized waveguide panel array antenna formed after the above seven-layer structure is assembled is shown.

[0022] The dielectric film 10 is made by screen-printing an oblique "cross" pattern 11 with a conductive ink on PET (polyethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com