A kind of high-content liquid gingerol and preparation method thereof

A high-content technology of gingerol, which is applied in the field of plant extracts and its preparation, can solve the problems of heavy metal residues in products, low separation efficiency, and high production costs, and achieve better product quality, good repeatability, and quality. Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the high-content liquid gingerol described in the present embodiment may further comprise the steps:

[0034] (1) With 0.5 kilogram of ginger resin, its gingerol content is 38.2%, the condition of supercritical carbon dioxide extraction is: extraction pressure / temperature 30MPA / 40 ℃, primary separation pressure / temperature 12MPA / 45 ℃, secondary separation pressure / Temperature 5MPA / 35°C. The ginger resin is obtained in the primary separator, and mainly volatile components in the secondary separator. Adding 2.25 kilograms of weight percent concentration in ginger resin is 70% ethanol aqueous solution, stirs, removes a small amount of insoluble matter by filtration, obtains clear ginger resin alcohol solution;

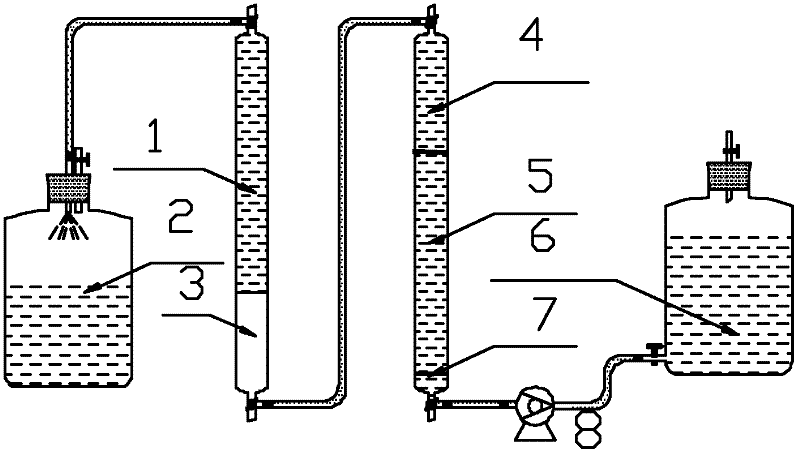

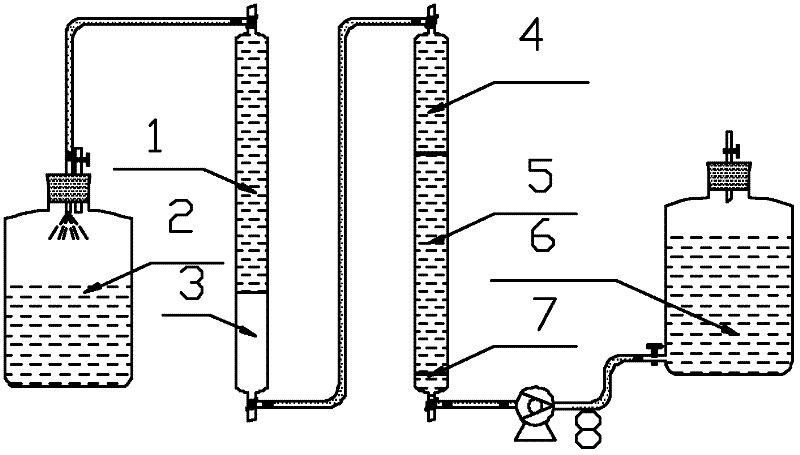

[0035] (2) if figure 1 As shown, the alcohol solution of the above-mentioned ginger resin is transferred to a glass liquid-liquid extractor (90 mm in diameter × 1100 mm in height), and then petroleum ether (boiling range 60 to 90° C.) i...

Embodiment 2

[0039] The preparation method of the high-content liquid gingerol described in the present embodiment may further comprise the steps:

[0040](1) With 1.0 kilograms of ginger resin, its gingerol content is 39.4%, the condition of supercritical carbon dioxide extraction is: extraction pressure / temperature 30MPA / 45 ℃, primary separation pressure / temperature 13MPA / 45 ℃, secondary separation pressure / Temperature 5MPA / 35°C. The ginger resin is obtained in the primary separator, and mainly volatile components in the secondary separator. Adding 4.0 kilograms of concentration by weight wherein is 75% ethanol aqueous solution, stirs, removes a small amount of insoluble matter by filtration, obtains clear ginger resin alcohol solution;

[0041] (2) the alcoholic solution of above-mentioned ginger resin is transferred in the glass liquid-liquid extractor (diameter 90 millimeters × height 1100 millimeters), then sherwood oil (boiling range 60~90 ℃) is passed through the bottom of the ex...

Embodiment 3

[0045] The preparation method of the high-content liquid gingerol described in the present embodiment may further comprise the steps:

[0046] (1) With 2.0 kilograms of ginger resin, its gingerol content is 37.1%, the condition of supercritical carbon dioxide extraction is: extraction pressure / temperature 32MPA / 45 ℃, primary separation pressure / temperature 14MPA / 50 ℃, secondary separation pressure / Temperature 5MPA / 35°C. The ginger resin is obtained in the primary separator, and mainly volatile components in the secondary separator. Adding 7.5 kilograms of weight percent concentration therein is the ethanol aqueous solution of 80%, stirs, removes a small amount of insoluble matter by filtration, obtains clear ginger resin alcohol solution;

[0047] (2) the alcoholic solution of above-mentioned ginger resin is transferred in the glass liquid-liquid extractor (diameter 110 millimeters × height 1300 millimeters), then with metering pump 8 petroleum ether (boiling range 60~90 ℃) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com