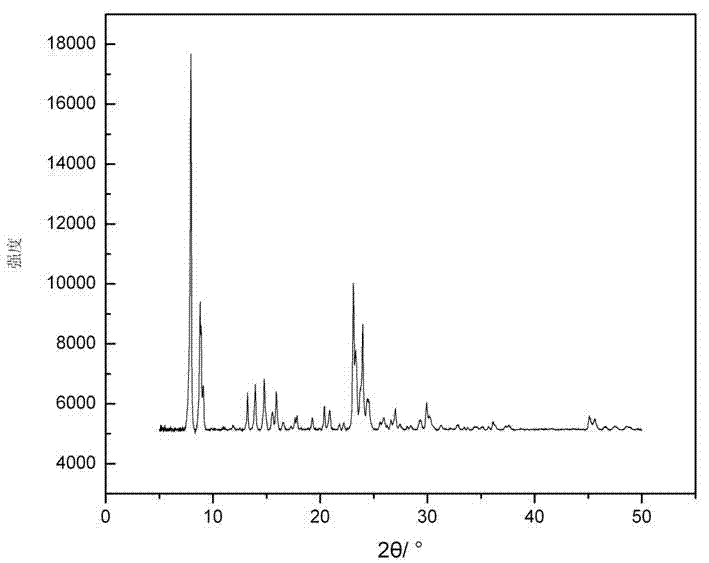

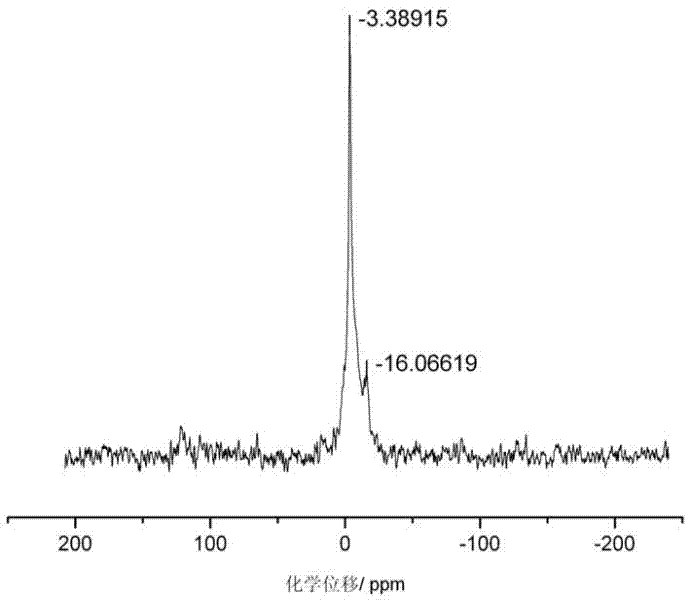

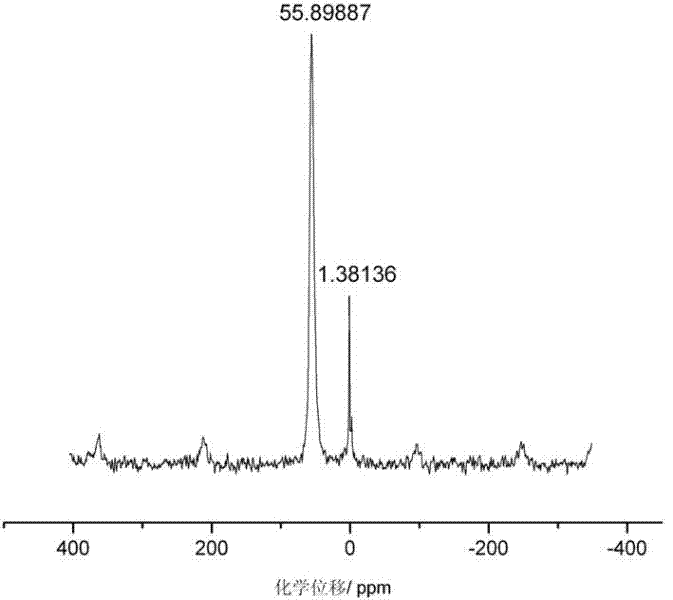

A kind of boron-containing zsm-5 zeolite catalyst for producing olefin from methanol and preparation method thereof

A zeolite catalyst, ZSM-5 technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low reaction conversion rate and weak acidity, and achieve high reaction space velocity and high crystallinity. , the effect of excellent catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation process and steps of this embodiment are as follows:

[0048] a. Preparation of the reaction mixture

[0049] Take the following materials: the silicon source is silica sol, the aluminum source is aluminum isopropoxide, the boron source is boric acid, the template agent is ethylenediamine and deionized water; each material is weighed by molar ratio, namely SiO 2 :Al 2 o 3 :B 2 o 3 : Templating agent: H 2 O = 1: 0.005: 0.05: 1.0: 10, to prepare a mixture solution; the process of preparing a mixture solution is: first mix the aluminum source, boron source and deionized water evenly, add the template agent under constant stirring, and wait to stir to form After clarifying the transparent liquid, continue to stir and slowly add the silicon source. After stirring evenly again, slowly add sulfuric acid to adjust the pH of the solution to neutral, and then add ammonia water to adjust the pH of the solution to 8~10. After further stirring (4~12h), a reacti...

Embodiment 2

[0055] In the preparation process of the catalyst in this example, water glass was used as the silicon source, aluminum sulfate was used as the aluminum source, and sodium tetraborate was used as the boron source. The synthesis steps are exactly the same as in Example 1, and the catalyst obtained is marked as HBZ5-2.

Embodiment 3

[0057] The steps in this embodiment are exactly the same as those in Embodiment 1 above. The difference is: in the preparation process of the reaction mixture, the silicon source adopts ethyl orthosilicate, the boron source adopts boron trichloride, and the template agent adopts tetrapropylammonium hydroxide; and the molar ratio of each substance is: SiO 2 :Al 2 o 3 :B 2 o 3 : Templating agent: H 2 O = 1:0.004:0.02:0.6:20; hydrothermal crystallization at 170°C for three days was used in the hydrothermal crystallization process; Molecular sieve (B-Al-ZSM-5) raw powder was subjected to ion exchange for three consecutive times, each time for 5 hours. Wherein the solution volume / product mass=10ml / g, and the ion exchange temperature is 85°C. The resulting catalyst was labeled HBZ5-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com